Imaginez la situation : Vous êtes en train d'installer un système de canalisation dans une usine à haute pression lorsqu'une question cruciale vous arrête en plein milieu de votre tâche...Les vannes papillon sont-elles directionnelles ?? Si vous vous trompez, votre vanne risque de fuir sous la pression ou de s'user prématurément. Il ne s'agit pas seulement d'un problème académique ; cela a un impact sur l'efficacité, la sécurité et le budget de votre projet.

J'ai vu cette confusion coûter des mois de dépannage à des équipes de maintenance. Démystifions vanne papillon de la dynamique des flux afin que vous les installiez correctement dès la première fois.

Le résultat ?

La plupart des vannes papillon sont bidirectionnelles, MAIS certains modèles fonctionnent de manière optimale avec un fluide circulant dans une direction spécifique. Vérifiez toujours les indications du fabricant.

Table des matières

- L'impact de la conception des vannes papillon sur le sens d'écoulement

- Pourquoi la direction de l'installation affecte-t-elle les performances ?

- Guide d'installation Pro : Optimisation de l'orientation des vannes

- Informations spécifiques à l'industrie

- Dépannage des problèmes liés à la direction du flux

- Conclusion : Quand les vannes papillon sont directionnelles

L'impact de la conception des vannes papillon sur le sens d'écoulement

Qu'est-ce qui définit la "direction" d'une vanne papillon ?

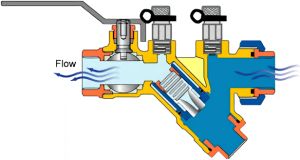

Les vannes papillon utilisent un disque circulaire monté sur une tige rotative. Lorsqu'il est ouvert, le fluide passe autour de Contrairement aux robinets à soupape, qui redirigent le flux par une trajectoire en S. Cette conception symétrique du noyau rend la plupart des modèles intrinsèquement bidirectionnel.

Cependant, toutes les vannes ne gèrent pas l'inversion de flux de la même manière. Les performances dépendent de :

- Géométrie des disques/joints

- Ingénierie offset

- Conditions de pression/température

Le comportement directionnel est dicté par trois conceptions principales :

| Type de vanne | Directionnalité | Pression d'écoulement idéale |

|---|---|---|

| Concentrique (décalage zéro) | Entièrement bidirectionnel | Basse pression (≤150 PSI) |

| Double décalage | Bidirectionnel (flux préférentiel recommandé) | Moyenne pression (150-750 PSI) |

| Triple décalage | Unidirectionnel (flux directionnel strict) | Haute pression/haute température (750+ PSI) |

Vannes papillon concentriques : Véritable bidirectionnalité

Ces vannes d'entrée de gamme positionnent le disque centré sur la tige et l'alésage. Résultat ? Des caractéristiques d'écoulement identiques dans les deux sens.

Pourquoi bidirectionnel ?

- Les sièges revêtus de caoutchouc assurent l'étanchéité du contact à 360° autour du disque.

- Répartition égale de la force en position fermée

- La conception simple permet de gérer les inversions de flux (par exemple, les arrêts de pompe).

Vannes à haute performance : Modèles décalés et débit préférentiel

Vannes papillon à double excentration (excentrique #1)

Ici, la tige est :

- Décalage derrière l'axe du disque

- Décalage par rapport à l'axe du tuyau (créant un mouvement de came)

Aperçu de la directionnalité:

- Techniquement bidirectionnel

- Recommandé : Installer avec le flux entrant dans le côté fort du disque (généralement contre l'offset)

- Le flux inversé augmente la turbulence de 15-22% (selon les tests de Velan)

La direction importe le plus dans les systèmes à plus de 15 barres", "la direction importe le plus dans les systèmes à plus de 15 barres". note Marie Tremblay, ingénieure au SLB. "Les vannes fonctionnent à contre-courant mais sont plus étanches dans la direction préférée.

Vannes papillon à triple excentration (haute performance)

Ces valves ajoutent une joint d'angle conique pour créer des joints d'étanchéité métal sur métal, ce qui les rend plus résistants :

- Presque étanche

- Résistant à plus de 1 000 PSI

- Strictement unidirectionnel

Pourquoi une contrainte directionnelle ? Le flux doit :

- Forcer le disque dans le scellé (et non le décoller)

- Prévenir l'usure du siège par les boues et les débris à grande vitesse

- Maintien d'un faible couple

Vous trouverez un Flèche d'écoulement gravée sur des marques réputées comme Bray et Jamesbury.

Pourquoi la direction de l'installation affecte-t-elle les performances ?

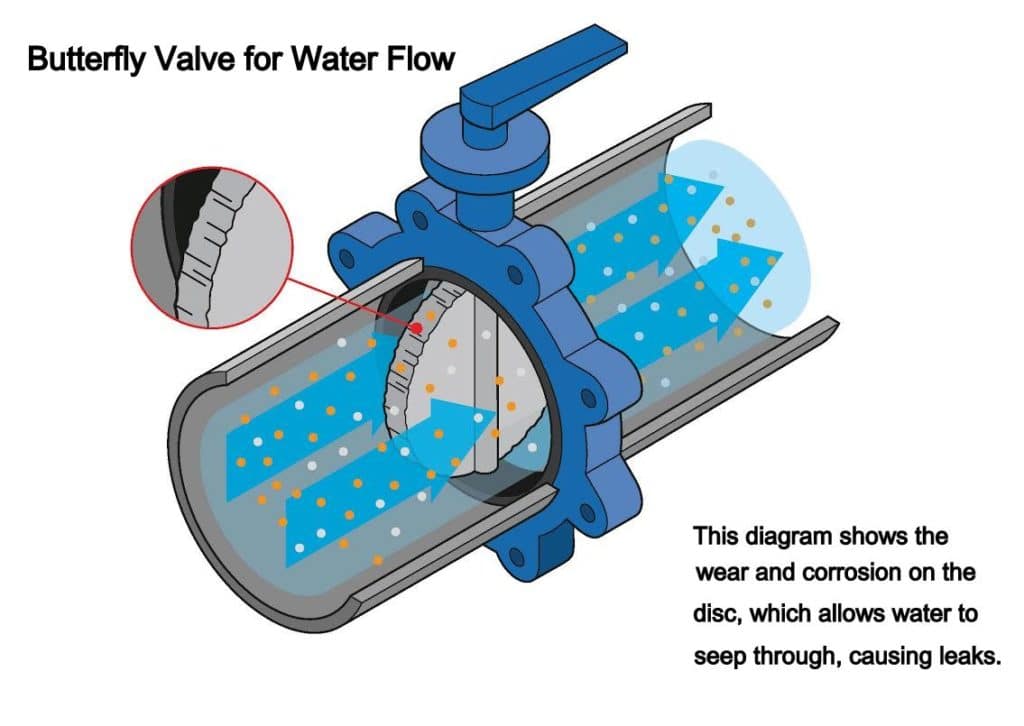

Les conséquences de l'inversion de flux

L'ignorance directionnelle n'est pas bénigne. Dans une installation de soupape à triple excentration qui a mal tourné :

- Déséquilibre de pression : L'écoulement éloigne le disque du siège → risque de fuite ↑ 300% (étude de cas Emerson)

- Usure prématurée : Les abrasifs ciblent les zones non durcies des disques

- Cavitation : Une mauvaise direction de l'écoulement entraîne la formation de bulles de vapeur → piqûres

Repérer les marques directionnelles

Les fabricants signalent leurs préférences en matière de flux via :

⬆️ Flèches en relief sur le corps de la vanne

⬆️ "FLOW" moulé dans la face de la bride

⬆️ Étiquettes de documentation (par exemple, "INSTALL SEAT UPSTREAM")

Les vannes à haute performance indiquent physiquement le sens du flux. Pas de flèche ? Probablement bidirectionnel.

Guide d'installation Pro : Optimisation de l'orientation des vannes

Étape 1 : Identifier le type de vanne

- Concentrique : Pas de décalage | siège élastique | alignement des trous de boulons

- Double décalage : Siège en caoutchouc/métal

- Triple décalage : 3 excentricités | siège métallique conique

Étape 2 : Déterminer la direction de l'écoulement (cas non concentriques)

- Trouver des marqueurs d'écoulement (flèches/coulées "INLET")

- Positionner la vanne à l'endroit où le flux entre dans le côté pression de disque

- Pas de marquage ? Consulter les fiches techniques/diagrammes

Étape 3 : Contrôles des positions critiques

| Paramètres | Meilleures pratiques | Éviter |

|---|---|---|

| Orientation de l'arbre | Horizontal | Verticale en cas de sédiments lourds |

| Écarts entre les brides | Espace uniforme <0,8 mm | Brides mal alignées |

| Position de l'actionneur | Zone accessible et protégée | Chemins d'écoulement de l'eau/des substances |

Informations spécifiques à l'industrie

🔄 Eau/eaux usées

Les cas d'écoulement inversé sont fréquents dans ce cas. Utilisez des vannes concentriques ou à double excentration avec des sièges en élastomère (par exemple, EPDM/Nitrile). Évitez les vannes à triple excentration, à moins qu'elles ne soient explicitement marquées comme étant bidirectionnelles.

🧪 Pétrole, gaz et produits chimiques

Le triple décalage domine dans :

- Unités de service hydrogène

- Lignes de transfert de pétrole brut

- Applications de vapeur à haute teneur en phosphore

La direction du flux régit la sécurité. Le rapport 2023 d'ExxonMobil mentionne des vannes inversées dans 40% des défaillances d'isolation des usines de GNL.

❄️ Systèmes CVC

Les boucles hydroniques inversent souvent le flux en fonction des saisons. Il faut s'en tenir à des modèles concentriques bidirectionnels comme la série 737 de Victaulic, qui ne dépendent pas de la direction.

Dépannage des problèmes liés à la direction du flux

Symptôme → Problématique probable → Fixer

La vanne se bloque lors de la fermeture → Débit installé à l'envers → Repositionner selon la flèche

Érosion du siège après 6 mois→ La direction expose le côté faible du joint → Réorienter le disque du côté fort vers l'avant

Fuite du siège sous pression → Disque de pelage à flux inversé → Installer avec le flux dans le sens de la flèche préférée

Conclusion : Quand les vannes papillon Sont Directionnel

Alors...Les vannes papillon sont-elles directionnelles ? Voici le récapitulatif pratique :

- ✅ Vannes concentriques : Entièrement bidirectionnel. Le sens du flux n'a pas d'importance.

- ⚠️ Valves à double excentration : Bidirectionnel, mais il faut s'attendre à une perte de charge supérieure de 10 à 60 PSI en cas d'écoulement inverse.

- ❌ Valves à triple excentration : Unidirectionnel. Suivre scrupuleusement les flèches de flux.

90% des erreurs d'installation impliquent ignorer les marquages des fabricants. Si vous ne vous souvenez de rien d'autre :

Localisez la flèche. Orienter le flux vers elle.

Les systèmes à haute pression ne tolèrent aucune approximation. En cas de doute ? Prenez une photo de votre vanne sans marqueur de débit et envoyez-la par courrier électronique au fabricant. Une requête de $5 minutes vaut mieux que $50 000 en temps d'arrêt imprévu.

Dernier conseil : Marquez les préférences en matière de flux lors de l'achat, et non de l'installation. Votre futur utilisateur (et l'équipe d'entretien) vous remerciera.

Soutenu par les normes de l'industrie : API 609, EN 593 et MSS-SP-67.

Vous avez un dilemme concernant les soupapes ? Partagez-le dans les commentaires.