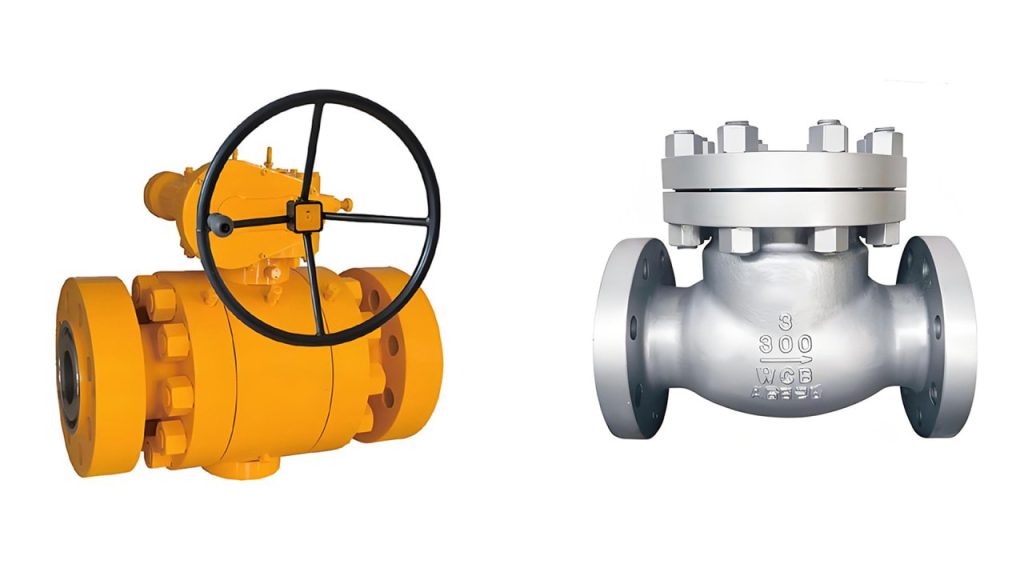

Les vannes sont des composants essentiels de tout système de traitement des fluides. Ils régulent le débit, assurent l'arrêt et empêchent les retours d'eau. Deux des types les plus courants sont les robinets à bille et les clapets anti-retour. Mais quand faut-il utiliser l'un ou l'autre ?

Je comparerai robinets à boisseau sphérique contre clapets anti-retour dans cet article, afin que vous sachiez exactement quand utiliser chaque type. Je couvrirai les points suivants :

- Comment ils fonctionnent

- Principales différences

- Applications

- Avantages et inconvénients

De plus, je vous aiderai à choisir ce qui convient le mieux à vos besoins spécifiques.

Table des matières

- Fonctionnement des robinets à bille et des clapets anti-retour

- Principales différences entre les robinets à bille et les clapets anti-retour

- Applications du robinet à boisseau sphérique et du clapet anti-retour

- Avantages et inconvénients du robinet à boisseau sphérique et du clapet anti-retour

- Choix entre un robinet à boisseau sphérique et un clapet anti-retour

Fonctionnement des robinets à bille et des clapets anti-retour

Tout d'abord, un aperçu rapide du fonctionnement de chaque type de soupape.

Vannes à bille

Les vannes à bille utilisent une bille rotative avec un alésage au milieu pour contrôler le débit. En tournant la bille de 90 degrés, vous pouvez passer d'une ouverture totale à une fermeture totale.

Schéma du robinet à boisseau sphérique

Les robinets à tournant sphérique assurent une fermeture positive lorsqu'ils sont fermés. Et lorsqu'ils sont ouverts, ils ont très peu de perte de charge ou de restriction de débit. Elles sont donc idéales pour les applications tout ou rien.

Clapets anti-retour

Les clapets anti-retour ne permettent l'écoulement que dans un sens ; ils empêchent le reflux. Ils utilisent l'énergie du fluide en circulation pour s'ouvrir automatiquement. Ils se ferment ensuite lorsque le flux s'arrête ou s'inverse.

Schéma du clapet anti-retour

Les clapets anti-retour les plus courants sont les clapets à battant, les clapets à bascule et les clapets à levage. Ils fonctionnent tous selon le même principe unidirectionnel.

Les clapets de non-retour à ressort ajoutent un ressort qui maintient l'étanchéité du clapet jusqu'à ce que la pression de la ligne surpasse la force du ressort.

Principales différences entre les robinets à bille et les clapets anti-retour

Maintenant que vous connaissez les bases de leur fonctionnement, examinons quelques différences essentielles :

1. Contrôle du débit

- Vannes à bille assurent un débit total lorsqu'ils sont ouverts et une fermeture positive lorsqu'ils sont fermés. Idéal pour les opérations fréquentes de marche/arrêt.

- Clapets anti-retour ne permettent qu'un débit unidirectionnel. Ils ne contrôlent pas le débit lorsqu'ils sont ouverts.

2. Fonctionnement automatique

- Vannes à bille nécessitent un actionnement manuel ou automatisé pour s'ouvrir ou se fermer.

- Clapets anti-retour fonctionnent automatiquement en fonction du débit et de la pression. Aucune commande externe n'est nécessaire.

3. Coût

- Vannes à bille coûtent généralement plus cher que les clapets de retenue de même taille. La conception du boisseau et du siège est plus complexe.

- Clapets anti-retour sont simples à l'intérieur. Il suffit d'un disque, d'une charnière et d'un siège. Ils sont relativement peu coûteux.

4. Chute de pression

- Vannes à bille ont une très faible perte de charge lorsqu'ils sont ouverts. Les vannes à passage intégral maintiennent le diamètre intérieur du tuyau.

- Clapets anti-retour induisent une perte de charge plus importante. Le débit doit faire fléchir le mécanisme de contrôle.

Applications du robinet à boisseau sphérique et du clapet anti-retour

Examinons maintenant les applications typiques pour lesquelles les robinets à boisseau sphérique ou les clapets anti-retour sont préférables.

Applications du robinet à boisseau sphérique

Les robinets à tournant sphérique se distinguent dans les applications qui requièrent :

- Opérations fréquentes de mise en marche et d'arrêt

- Arrêt positif en cas de fermeture

- Faible perte de charge en cas d'ouverture

- Possibilité d'étrangler/équilibrer le débit

Applications courantes des robinets à tournant sphérique :

- Contrôle des processus

- Systèmes à vapeur

- Injection de produits chimiques

- Isolation des branches

- Mélange ou détournement de services

Applications des clapets anti-retour

Les clapets anti-retour sont conçus pour :

- Empêcher l'inversion du flux

- Éviter d'endommager la pompe ou le processus en cas de reflux

- Empêcher le reflux des contaminants dans l'eau potable

Applications typiques des clapets anti-retour :

- Prévention des retours d'eau

- Décharge de la pompe

- Lignes d'alimentation par gravité

- Climatisation et réfrigération

Avantages et inconvénients du robinet à boisseau sphérique et du clapet anti-retour

Enfin, résumons les avantages et les inconvénients uniques des robinets à boisseau sphérique par rapport aux clapets de non-retour :

Pros du robinet à boisseau sphérique

- Fermeture positive

- Plein débit en cas d'ouverture

- Gestion des cycles fréquents

- Variété de configurations et de tailles

- Régule le débit lorsqu'il est utilisé pour l'étranglement

Valve à bille Cons

- Coût initial plus élevé

- Nécessite des contrôles manuels ou automatisés

- Difficile à automatiser par rapport à d'autres types de vannes

Clapet anti-retour Pros

- Aucune alimentation ou commande externe n'est nécessaire

- Empêche automatiquement les retours d'eau

- Conception simple avec une seule pièce mobile

- Faible coût d'achat

Clapet anti-retour Cons

- Perte de pression permanente

- Capacité limitée de contrôle du débit

- Peut se bloquer en ouverture/fermeture en fonction de l'installation

- Les pièces mobiles peuvent s'user avec le temps

Choix entre un robinet à boisseau sphérique et un clapet anti-retour

Comme vous pouvez le constater, les robinets à tournant sphérique et les clapets anti-retour présentent tous deux des avantages uniques. Souvent, ce sont les exigences de l'application qui dictent le meilleur choix.

Pour une fermeture positive et une restriction minimale du débit, robinets à boisseau sphérique l'emportent presque toujours.

Pour empêcher automatiquement l'inversion du flux, clapets anti-retour sont idéales.

Dans certaines applications, vous pouvez avoir besoin des deux ! Les robinets à boisseau sphérique permettent d'isoler des sections de conduites et d'arrêter manuellement le débit. Les clapets anti-retour, quant à eux, assurent une protection automatique contre les retours d'eau aux points clés.

Quel que soit le style que vous choisirez, veillez à sélectionner des valves de qualité provenant de fabricants réputés tels que Flomatic ou Vanne Zeco. Payer un peu plus pour la durabilité et la performance en vaut presque toujours la peine lorsqu'il s'agit de lignes critiques.

Voilà qui conclut cette comparaison entre robinet à boisseau sphérique et clapet anti-retour ! Vous connaissez maintenant les différences, les applications typiques et les cas où il est préférable d'utiliser chaque type.

Si vous avez d'autres questions sur les vannes, n'hésitez pas à m'en faire part. Je suis toujours heureux de discuter davantage des systèmes de plomberie et de traitement des fluides !