Vous êtes-vous déjà demandé comment un clapet anti-retour pour éviter des catastrophes coûteuses dues au reflux dans vos systèmes de plomberie ou industriels ? Ces dispositifs ingénieux bloquent automatiquement les flux inversés sans aucune alimentation ou commande externe. En fait, les clapets anti-retour évitent chaque année des millions de dollars de dommages aux équipements en permettant simplement au fluide de s'écouler dans une seule direction.

Aujourd'hui, je vais vous montrer exactement comment fonctionnent les composants du clapet de non-retour, les différents types disponibles et comment choisir le bon clapet pour vos besoins spécifiques.

Table des matières

- Qu'est-ce qu'un clapet anti-retour (et pourquoi s'en préoccuper) ?

- Le principe de fonctionnement de base (c'est plus simple que vous ne le pensez)

- Types de clapets anti-retour (et quand les utiliser)

- Applications réelles (où vous trouverez ces vannes)

- Problèmes courants (et comment les résoudre)

- Meilleures pratiques d'installation (réussir du premier coup)

- Conseils d'entretien (pour que vos vannes fonctionnent comme si elles étaient neuves)

- Choisir le bon clapet anti-retour (cadre décisionnel)

- Applications avancées et conceptions spéciales

- Normes et spécifications de l'industrie

- L'essentiel sur le fonctionnement des clapets anti-retour

Qu'est-ce qu'un clapet anti-retour (et pourquoi s'en préoccuper) ?

Voici ce qu'il en est :

Un clapet anti-retour est en fait une vanne à sens unique pour les fluides. Il est également appelé clapet anti-retour ou vanne à sens unique.

Il fait exactement ce que son nom suggère : il "vérifie" la direction du flux et n'autorise le mouvement que dans une seule direction.

Et le plus beau, c'est qu'il fonctionne automatiquement. Il fonctionne automatiquement. Pas d'électricité. Pas d'opération manuelle. Pas de système de contrôle complexe.

C'est du pur génie mécanique.

Pensez-y de la manière suivante : Imaginez une porte qui ne pivote que dans un sens. Lorsque vous poussez du côté droit, elle s'ouvre facilement. Mais essayez de pousser du mauvais côté ? Ce n'est pas possible.

C'est essentiellement ce que fait un clapet anti-retour pour l'écoulement des liquides ou des gaz.

Le principe de fonctionnement de base (c'est plus simple que vous ne le pensez)

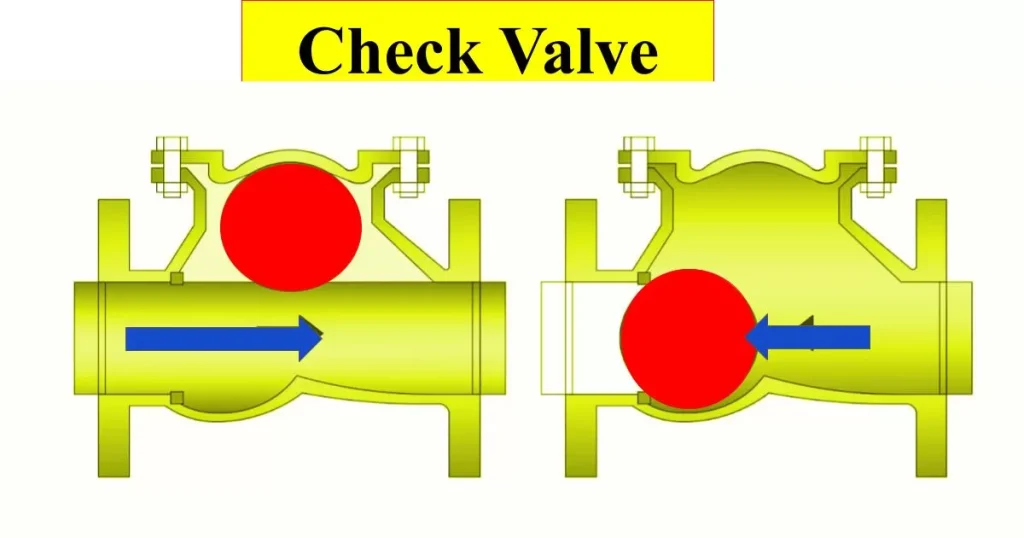

Le mécanisme de fonctionnement d'un clapet anti-retour est étonnamment simple.

Tout se résume à pression différentielle.

Lorsque la pression d'entrée dépasse la pression de sortie d'une certaine valeur (appelée "pression de rupture"), la soupape s'ouvre. Lorsque cette relation de pression s'inverse ou s'égalise, la soupape se ferme brusquement.

Voici ce qui se passe étape par étape :

1. Mode "Forward Flow" (flux vers l'avant)

La pression en amont pousse contre l'élément de fermeture de la vanne (qui peut être un disque, une bille ou un diaphragme). Une fois que cette pression a surmonté la résistance de la vanne, celle-ci s'ouvre et permet l'écoulement.

2. Mode sans débit

Lorsque la pression s'équilibre ou tombe en dessous de la pression de tarage, la gravité ou un ressort repousse l'élément de fermeture vers son siège. La soupape est alors fermée.

3. Prévention de l'écoulement inverse

Si la pression tente de s'écouler vers l'arrière, elle pousse en fait l'élément de fermeture plus fort contre le siège, créant ainsi un joint encore plus étanche.

Plutôt malin, non ?

Types de clapets anti-retour (et quand les utiliser)

Tous les clapets de non-retour ne sont pas identiques.

Des applications différentes nécessitent des conceptions différentes. Permettez-moi d'en présenter les principaux types :

Clapets anti-retour à battant

Il s'agit de l'outil de travail par excellence dans le domaine des clapets anti-retour.

Un disque est suspendu à une charnière et s'ouvre lorsque l'écoulement se fait vers l'avant. Lorsque le flux s'arrête ou s'inverse, la gravité (et la contre-pression) le fait basculer vers la fermeture.

Meilleur pour : Conduites de grand diamètre, applications à faible chute de pression, installations horizontales

Les inconvénients : Ils peuvent provoquer des coups de bélier s'ils se referment trop rapidement.

Clapets anti-retour à bille

Au lieu d'un disque oscillant, ils utilisent une boule sphérique qui se soulève de son siège.

La bille peut être flottante ou à ressort. L'écoulement vers l'avant pousse la bille vers le haut et l'éloigne. L'écoulement inverse (ou la gravité) la repousse vers le bas pour l'étanchéifier.

Meilleur pour : Fluides visqueux, applications à écoulement vertical, espaces compacts

Les inconvénients : Perte de charge plus importante que pour les types à oscillation

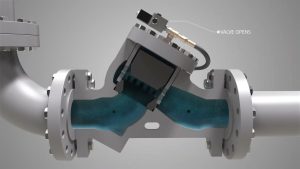

Clapets de non-retour à ressort

Ces mauvais garçons utilisent un ressort pour faciliter la fermeture.

Le grand avantage ? Ils fonctionnent dans n'importe quelle orientation - horizontale, verticale, et même à l'envers. Le ressort assure une fermeture rapide et positive, indépendamment de la gravité.

Meilleur pour : Angle d'installation quelconque, fermeture rapide, prévention des coups de bélier

Les inconvénients : Augmente la perte de charge en raison de la résistance du ressort

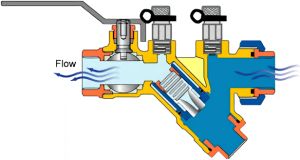

Clapets anti-retour à levage

Imaginez un piston qui monte et descend dans un cylindre.

C'est essentiellement ainsi que fonctionne un clapet anti-retour à levée. Le disque se soulève directement de son siège lorsque le débit le pousse. Le fonctionnement est assez similaire à celui des clapets à bille, mais avec un disque guidé à la place.

Meilleur pour : Applications à haute pression, systèmes à vapeur, contrôle précis du débit

Les inconvénients : Doit être installé dans des orientations spécifiques

Applications réelles (où vous trouverez ces vannes)

Les clapets anti-retour sont littéralement partout. Et je dis bien partout.

Permettez-moi de vous présenter quelques applications courantes :

Dans votre maison :

- Conduites de refoulement de la pompe de puisard (empêche l'eau pompée de refluer)

- Chauffe-eau (empêche l'eau chaude de refouler dans les conduites froides)

- Systèmes d'irrigation (empêche la saleté et les débris de pénétrer dans les conduites d'alimentation)

- Pompes de puits (maintien de l'amorçage et prévention des retours d'eau)

Applications industrielles :

- Traitement chimique (évite les mélanges chimiques dangereux)

- Raffineries de pétrole (protège les équipements coûteux contre l'écoulement inverse)

- Centrales électriques (maintient le sens d'écoulement de l'eau d'alimentation de la chaudière)

- Traitement des eaux usées (empêche le reflux des eaux usées)

Utilisations spécialisées :

- Dispositifs médicaux (débit unidirectionnel dans les lignes IV et les respirateurs)

- Automobile (systèmes de carburant et conduites de frein)

- Systèmes CVC (contrôle du débit du réfrigérant)

- Systèmes de protection contre l'incendie (maintien de la pression de l'eau)

Problèmes courants (et comment les résoudre)

Même les meilleurs clapets de non-retour peuvent présenter des problèmes.

Voici les problèmes les plus courants que je rencontre :

Coups de bélier

Il s'agit du bruit "BANG !" que l'on entend lorsqu'une soupape se ferme.

Ce phénomène se produit lorsque l'eau en mouvement rapide s'arrête soudainement, créant une onde de pression. La solution ? Installer une vanne à fermeture plus lente ou ajouter un dispositif anti-bélier.

Bruit des soupapes

Si votre valve semble applaudir, c'est qu'il y a du bavardage.

Cela signifie généralement que la vanne est surdimensionnée par rapport à votre débit. Le disque ou la bille s'ouvre et se ferme constamment au lieu de rester dans une seule position.

Fixer : Dimensionner correctement la vanne ou ajuster les débits du système

Fuites internes

Le mode de défaillance #1 pour les clapets de retenue.

Avec le temps, les surfaces d'étanchéité s'usent ou sont endommagées par des débris. Résultat ? Le clapet n'est pas complètement étanche et permet un certain retour d'eau.

Fixer : Entretien et nettoyage réguliers, ou remplacement des vannes

Blocage de l'ouverture ou de la fermeture

CorrosionL'accumulation d'eau, de débris ou de minéraux peut entraîner le blocage du mécanisme de la vanne.

Fixer : Rinçage et entretien réguliers, choix du matériau approprié pour votre fluide

Meilleures pratiques d'installation (réussir du premier coup)

Vous voulez que votre clapet de non-retour dure longtemps ? Suivez ces conseils d'installation :

1. Vérifier le sens d'écoulement

Je ne saurais vous dire combien de clapets anti-retour j'ai vus. Recherchez la flèche sur le corps du clapet. Elle DOIT être orientée dans le sens du débit.

2. Fournir des conduites droites

Installer avec au moins 5 diamètres de tuyau droit en amont. Cela permet d'assurer un écoulement régulier et non turbulent dans la vanne.

3. Considérer l'orientation

Toutes les vannes ne fonctionnent pas dans toutes les positions. Les clapets à bascule doivent être horizontaux. Les types à ressort sont plus flexibles.

4. La bonne taille

Une soupape surdimensionnée provoque des claquements. Une vanne sous-dimensionnée crée une chute de pression excessive. Utiliser les tableaux de dimensionnement du fabricant.

5. Compatibilité des matériaux

Assurez-vous que les matériaux de vos vannes sont compatibles avec votre fluide. L'acier inoxydable pour les produits corrosifs, le laiton pour l'eau, les alliages spéciaux pour les conditions extrêmes.

Conseils d'entretien (pour que vos vannes fonctionnent comme si elles étaient neuves)

Voici ce qu'il faut savoir sur les clapets de non-retour :

Ils sont souvent oubliés jusqu'à ce qu'ils échouent. Ne commettez pas cette erreur.

Calendrier des inspections régulières :

- Inspection visuelle : Tous les mois

- Tests opérationnels : Tous les trimestres

- Inspection interne : Annuellement

Ce qu'il faut rechercher :

- Fuites externes ou corrosion

- Bruits inhabituels pendant le fonctionnement

- La perte de charge augmente

- Signes d'usure des connexions

Maintenance préventive :

- Rincer régulièrement les conduites pour éviter l'accumulation de débris

- Actionner périodiquement les vannes dans les systèmes à faible débit

- Remplacer les joints et les sièges usés avant qu'ils ne tombent en panne.

- Tenir des registres d'entretien détaillés

Choisir le bon clapet anti-retour (cadre décisionnel)

Choisir le bon clapet anti-retour n'est pas sorcier. Mais vous devez tenir compte de plusieurs facteurs :

Caractéristiques d'écoulement :

- Plage de débit

- Exigences en matière de pression

- Températures extrêmes

- Propriétés des fluides (viscosité, corrosivité, teneur en solides)

Contraintes d'installation :

- Espace disponible

- Orientation des tuyaux

- Accès pour la maintenance

- Types de connexions nécessaires

Exigences de performance :

- Perte de charge acceptable

- Exigences en matière de vitesse de fermeture

- Tolérance de fuite

- Durée de vie prévue

Considérations relatives aux coûts :

- Prix d'achat initial

- Complexité de l'installation

- Exigences en matière d'entretien

- Fréquence de remplacement

Applications avancées et conceptions spéciales

Le concept de base du clapet anti-retour a donné naissance à de nombreux modèles spécialisés :

Clapets anti-retour à double disque

Utilise deux disques à ressort qui s'ouvrent par le centre. Super compact et à fermeture rapide.

Clapets anti-retour à disque inclinable

Le disque bascule sur un axe décalé plutôt que de s'ouvrir complètement. Il réduit les coups de bélier tout en maintenant une faible perte de charge.

Vannes à bec de canard

Fabriqué à partir d'élastomères flexibles qui ressemblent... à un bec de canard. Idéal pour les boues et les fluides chargés de solides.

Valves de pied

Il s'agit en fait d'un clapet de non-retour auquel est attachée une crépine. Il maintient les conduites d'aspiration de la pompe amorcées et exemptes de débris.

Normes et spécifications de l'industrie

Les clapets anti-retour de qualité répondent à des normes rigoureuses :

- API 594/598 : Normes de l'industrie pétrolière

- ASME B16.34 : Pressions et températures nominales

- MSS SP-61 : Exigences en matière d'essais sous pression

- NSF 61 : Certification de la sécurité de l'eau potable

Vérifiez toujours que votre vanne est conforme aux normes applicables à votre application.

L'essentiel sur le fonctionnement des clapets anti-retour

Ainsi, Comment fonctionne un clapet anti-retour ??

C'est magnifiquement simple - la pression différentielle l'ouvre pour l'écoulement vers l'avant et il se ferme automatiquement pour empêcher l'écoulement vers l'arrière. Pas d'alimentation externe, pas de commandes complexes, juste un fonctionnement mécanique fiable.

Qu'il s'agisse de protéger un compresseur d'une valeur d'un million de dollars ou d'empêcher une pompe de puisard de fonctionner à l'envers, la compréhension du fonctionnement des clapets de non-retour vous aide à sélectionner, installer et entretenir correctement ces composants essentiels.

N'oubliez pas : Le bon clapet de non-retour dans la bonne application, installé correctement et entretenu régulièrement, assurera des années de service sans problème.

C'est le tableau complet de Comment fonctionne un clapet anti-retour ? - des principes de base aux applications avancées.