Voici ce qu'il en est :

Les vannes d'air peuvent sembler être des dispositifs simples, mais elles sont en fait les héros méconnus des systèmes de distribution d'eau. Comment un soupape d'air travail ? En termes simples, ces dispositifs mécaniques contrôlent automatiquement le mouvement de l'air à l'intérieur et à l'extérieur des pipelines à l'aide d'un mécanisme de flotteur qui fonctionne selon les principes de la flottabilité. Ils libèrent l'air emprisonné en fonctionnement normal, admettent de l'air pour empêcher la formation de vide et évacuent l'air pendant le remplissage de la canalisation.

Mais il y a bien plus que cela.

En fait, si les vannes d'air ne fonctionnent pas correctement, votre système de canalisation peut être confronté à de graves problèmes tels que des coups de bélier, une réduction de l'efficacité du débit, voire un effondrement catastrophique de la canalisation.

Aujourd'hui en tant que professionnel fabricant de vannes d'airDans ce numéro, je vais expliquer exactement comment fonctionnent les soupapes d'air, pourquoi elles sont importantes et comment en tirer le meilleur parti.

Table des matières

- Qu'est-ce qu'une vanne d'air ?

- La science derrière le fonctionnement du mécanisme du flotteur

- Types de vannes d'air (et quand les utiliser)

- Pourquoi les vannes d'air sont-elles essentielles pour l'efficacité des pipelines ?

- Placement stratégique : Où installer les vannes d'air

- Les meilleures pratiques d'installation qui comptent vraiment

- Problèmes courants (et comment les résoudre)

- Applications avancées à connaître

- Considérations sur le retour sur investissement et les coûts

- L'essentiel sur le fonctionnement des vannes d'air

Qu'est-ce qu'une vanne d'air ?

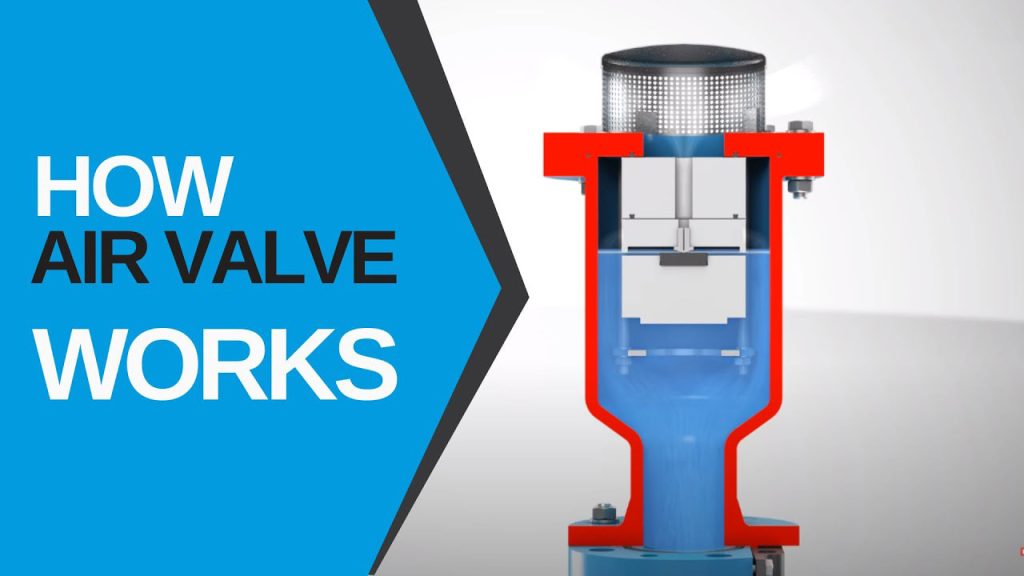

Un soupape d'air est un dispositif de contrôle de débit hydromécanique conçu pour gérer automatiquement l'air dans les systèmes de tuyauterie liquide.

Considérez-le comme le système respiratoire de votre pipeline.

Ces vannes remplissent trois fonctions essentielles :

- Dégagement d'air en cours de fonctionnement - Ventiler en permanence les petites poches d'air qui s'accumulent

- Admission d'air pendant la vidange - Prévenir les conditions de vide dangereuses

- Libérer l'air pendant le remplissage - Evacuation rapide de grands volumes d'air lors du remplissage de tuyaux vides

La beauté des vannes pneumatiques ? Elles fonctionnent automatiquement sans alimentation externe ni intervention manuelle.

La science derrière le fonctionnement du mécanisme du flotteur

Entrons maintenant dans le vif du sujet.

La plupart des vannes d'air utilisent un mécanisme du flotteur qui fonctionne selon un principe simple : la flottabilité.

Voici comment cela fonctionne :

Lorsque le pipeline est plein (fonctionnement normal)

Lorsque votre canalisation fonctionne normalement, le liquide remplit le corps de la vanne. Le flotteur à l'intérieur s'élève avec le niveau du liquide, tout comme un flotteur de pêche. Ce mouvement ascendant pousse le flotteur contre un petit orifice (ouverture), créant ainsi un joint qui maintient la vanne fermée.

Aucun liquide ne s'échappe. Aucun problème.

Quand l'air s'accumule

Mais c'est là que les choses deviennent intéressantes.

Lorsque de petites poches d'air s'accumulent dans la soupape, elles déplacent le liquide. Le niveau du liquide baisse, tout comme le flotteur. Lorsque le flotteur descend suffisamment bas, il s'éloigne de l'orifice et ouvre la soupape.

L'air emprisonné s'échappe dans l'atmosphère jusqu'à ce que le liquide pénètre à nouveau dans la soupape, soulevant le flotteur et l'obturant à nouveau.

Ce cycle se répète automatiquement en cas d'accumulation d'air.

Dans des conditions de vide

Lorsqu'une canalisation se vide ou subit une chute de pression soudaine, la situation devient critique.

Le liquide s'échappe du corps de la soupape, ce qui fait tomber complètement le flotteur. Cela ouvre un grand orifice, permettant à des volumes massifs d'air de s'engouffrer. Cette ouverture permet à l'air de s'engouffrer. prévention du vide est cruciale - sans elle, vos tuyaux pourraient littéralement s'effondrer sous l'effet de la pression négative.

Types de vannes d'air (et quand les utiliser)

Toutes les soupapes d'air ne sont pas égales.

En fait, choisir le mauvais type de valve peut être aussi néfaste que de ne pas en avoir du tout.

En voici les trois principaux types :

1. Valves d'échappement d'air

Meilleur pour : Libération de petites accumulations continues d'air sous pression

Comment ils fonctionnent : Conception à petit orifice avec système de flotteur pondéré

Caractéristiques principales :

- Libère les bulles d'air pendant le fonctionnement normal

- Fonctionne sous la pression totale du système

- Capacité limitée pour les grands volumes d'air

2. Vannes d'air/de vide

Meilleur pour : Protection contre les conditions de vide et les opérations de remplissage/vidange

Comment ils fonctionnent : Grand orifice normalement ouvert, qui se ferme lorsque l'eau pénètre dans l'appareil.

Caractéristiques principales :

- Admission rapide de grands volumes d'air

- Prévient l'effondrement des pipelines

- Ne peut pas relâcher l'air sous pression

3. Vannes d'air combinées

Meilleur pour : Gestion complète de l'air (mon préféré)

Comment ils fonctionnent : Incorpore à la fois les petits et les grands orifices dans une seule unité

Caractéristiques principales :

- Traite tous les soupape d'air fonctions

- L'option la plus polyvalente

- Un coût plus élevé mais une meilleure protection

Pourquoi les vannes d'air sont-elles essentielles pour l'efficacité des pipelines ?

Soyons clairs :

Ignorer l'air dans vos canalisations, c'est comme ignorer le cholestérol dans vos artères. Un jour ou l'autre, quelque chose va céder.

Voici ce qui se passe en l'absence de soupapes d'air adéquates :

Efficacité de pompage réduite

Les poches d'air créent des blocages qui obligent les pompes à travailler davantage. J'ai vu des systèmes où l'air emprisonné augmentait la consommation d'énergie de 15-20%.

C'est de l'argent bien réel qui est jeté par les fenêtres.

Coups de bélier et dégâts dus à la surtension

Lorsque des poches d'air se détachent et se déplacent vers l'aval, elles peuvent provoquer des coups de bélier dévastateurs. Il s'agit de forces qui peuvent littéralement déchirer les canalisations.

Erreurs de mesure

Les bulles d'air perturbent les débitmètres et les instruments. Vous ne pouvez pas gérer ce que vous ne pouvez pas mesurer avec précision.

Accélération de la corrosion

L'oxygène contenu dans l'air emprisonné accélère la canalisation corrosionsurtout aux points de température élevés. Cela réduit considérablement la durée de vie des pipelines.

Placement stratégique : Où installer les vannes d'air

Avec les soupapes d'air, l'emplacement est primordial.

Si vous les installez au mauvais endroit, ils deviendront des décorations coûteuses.

C'est ici que vous avez besoin de soupapes d'air :

Points forts du pipeline

L'air s'élève naturellement et s'accumule aux sommets. Il s'agit de la priorité #1 pour soupape d'échappement d'air placement.

Longs parcours horizontaux

Même les conduites "plates" présentent de légères variations d'altitude où l'air s'accumule. Sur les longues distances, installez des vannes tous les 1 500 à 2 500 pieds.

Modification de la pente de la canalisation

Tout endroit où le pipeline passe d'une position ascendante à une position descendante doit être protégé.

Après les pompes et les surpresseurs

Les pompes peuvent introduire de l'air par cavitation ou par des fuites au niveau des joints. Il faut toujours installer des vannes combinées en aval.

Vannes avant et après

Les vannes d'isolement, les vannes de contrôle et les robinets à soupape créent des turbulences qui libèrent de l'air dissous.

Les meilleures pratiques d'installation qui comptent vraiment

Voici ce qu'il en est :

Même les meilleurs soupape d'air ne fonctionnera pas s'il est mal installé.

Suivez les lignes directrices suivantes :

Toujours installer verticalement

Les soupapes d'air doivent être montées verticalement, avec l'entrée orientée vers le bas. Toute autre orientation les rendrait inopérantes.

Ajouter des vannes d'isolation

Installer un robinet d'arrêt sous chaque soupape d'air. Vous me remercierez au moment de l'entretien.

Assurer une bonne ventilation

Les vannes d'air ont besoin de respirer. Installez-les à un endroit où l'air expulsé peut s'échapper et où l'air frais peut entrer librement.

Dimensionner correctement

Les soupapes sous-dimensionnées ne peuvent pas faire face à l'accumulation d'air. Les vannes surdimensionnées gaspillent de l'argent. Utilisez les tableaux de dimensionnement des fabricants en fonction du diamètre des conduites et des débits.

Problèmes courants (et comment les résoudre)

Même si l'installation est correcte, des problèmes peuvent survenir.

Voici les problèmes les plus courants que je rencontre :

Le clapet ne libère pas l'air

Cause : En général, des débris bloquent l'orifice

Fixer : Démonter et nettoyer soigneusement

Décharge d'eau continue

Cause : Flotteur endommagé ou joints usés

Fixer : Remplacer les composants internes

Bruit des soupapes

Cause : Vanne surdimensionnée ou écoulement turbulent

Fixer : Installer un dispositif d'étranglement ou redimensionner la vanne

Échec prématuré

Cause : Matériau de soupape inadapté à l'application

Fixer : Passage à des matériaux appropriés (acier inoxydable pour les environnements corrosifs)

Applications avancées à connaître

Les vannes d'air ne sont pas réservées aux conduites d'eau.

Voici quelques applications spécialisées :

Systèmes d'assainissement

Les eaux usées génèrent des gaz par décomposition. Les vannes d'air spéciales pour eaux usées traitent ces gaz corrosifs tout en évitant l'encrassement.

Traitement chimique

Les vannes en acier inoxydable dotées de joints spéciaux traitent les produits chimiques agressifs en toute sécurité.

Systèmes à haute pression

Les vannes renforcées supportent des pressions allant jusqu'à 300 PSI pour les applications industrielles.

Considérations sur le retour sur investissement et les coûts

Parlons argent.

Les soupapes d'air de qualité ne sont pas bon marché. Mais ce n'est pas non plus le cas :

- Remplacement des canalisations éclatées

- Augmentation des coûts énergétiques

- Temps d'arrêt du système

- Défaillance prématurée de la pompe

J'ai vu des soupape d'air L'installation est amortie en 12 à 18 mois rien que par les économies d'énergie réalisées.

L'essentiel sur le fonctionnement des vannes d'air

Comment un soupape d'air travail ? Grâce à l'utilisation ingénieuse des principes de flottabilité et de la fonctionnement automatiqueCes dispositifs protègent les pipelines contre les problèmes liés à l'air sans nécessiter d'alimentation électrique ou d'intervention manuelle. Les mécanisme du flotteur monte et descend avec les niveaux de liquide, ouvrant et fermant les orifices pour libérer l'air emprisonné, admettre de l'air dans des conditions de vide, et maintenir un niveau optimal d'humidité. efficacité des pipelines. Qu'il s'agisse de gérer poches d'air à points forts du pipeline Les vannes d'air sont des composants essentiels qui permettent à nos systèmes d'alimentation en eau et d'assainissement de fonctionner correctement ou d'éviter un effondrement catastrophique du vide. systèmes d'eau Le trafic se fait de manière fluide et en toute sécurité.