Lorsqu'il s'agit de gérer la circulation des fluides dans un environnement industriel ou commercial, les vannes jouent un rôle crucial. Deux des types de vannes les plus courants sont les vannes à clapet et les Vannes.

Mais comment savoir lequel utiliser pour votre application spécifique ?

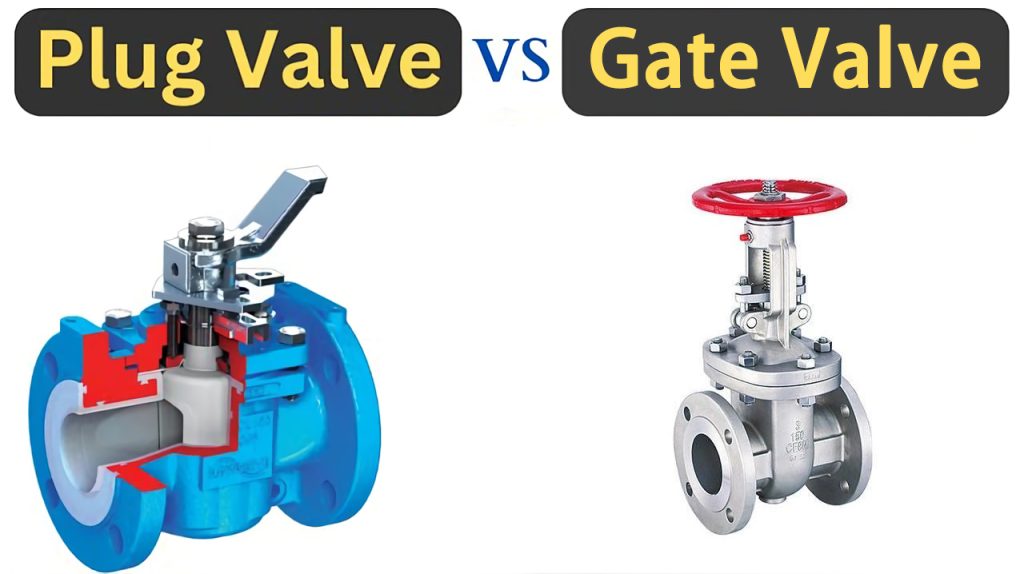

Dans ce guide complet, nous comparerons les robinets à tournant conique et les robinets-vannes pour vous aider à faire le bon choix. Nous aborderons tous les aspects, de la conception et du fonctionnement aux facteurs de performance, en passant par les applications et la maintenance.

Table des matières

- Quelles sont les différences de conception entre les robinets à tournant conique et les robinets-vannes ?

- En quoi leur fonctionnement et leurs performances diffèrent-ils ?

- Quelles sont les applications qui conviennent aux robinets à tournant conique ou aux robinets-vannes ?

- Quelle est la différence entre l'installation et l'entretien ?

- Conclusion : Choisir la meilleure vanne pour votre application

Quelles sont les différences de conception entre les robinets à tournant conique et les robinets-vannes ?

La principale différence entre ces deux types de vannes réside dans leur mécanisme interne et dans la manière dont elles régulent le flux de fluide.

Conception du robinet à boisseau conique

Comme son nom l'indique, un robinet à tournant conique utilise un tournant cylindrique ou conique dont le centre est percé d'un passage. En faisant pivoter ce clapet de 90 degrés, vous pouvez aligner ou décaler le passage avec les orifices d'entrée et de sortie.

Lorsqu'ils sont ouverts, les orifices se connectent à travers le bouchon percé, ce qui permet au fluide de s'écouler. Lorsqu'il est fermé, le bouchon bloque les orifices, ce qui arrête le débit.

Les robinets à tournant conique existent en modèles lubrifiés ou non lubrifiés. Les robinets à tournant conique lubrifiés conviennent bien aux liquides à haute température tels que les huiles. Les robinets non lubrifiés sont dotés d'un manchon pour les fluides à basse température.

Conception des robinets-vannes

Les robinets-vannes fonctionnent de manière très différente. Au lieu d'un clapet rotatif percé, ils utilisent une vanne solide qui coulisse perpendiculairement à la voie d'écoulement.

Pour ouvrir et fermer la vanne, il faut lever et abaisser cette vanne. Lorsqu'elle est ouverte, l'opercule se soulève pour sortir de la voie d'écoulement, laissant une ouverture libre pour le fluide. En fermant la vanne, l'opercule s'abaisse pour bloquer l'écoulement.

La plupart des robinets-vannes ont une tige montante, ce qui signifie que la tige sort du chapeau lorsque vous ouvrez le robinet. Cela permet d'obtenir un indicateur visuel de l'état du robinet. Les modèles à tige non montante gardent la tige à l'intérieur, ce qui permet de gagner de la place mais de perdre l'indicateur.

En quoi leur fonctionnement et leurs performances diffèrent-ils ?

Au-delà de leur conception de base, les robinets à tournant conique et les robinets-vannes se distinguent par divers facteurs de performance et de fonctionnement.

Comparaison des opérations

L'une des principales différences est la vitesse de fonctionnement. Les robinets à tournant conique ne nécessitent qu'une rotation de 90 degrés pour s'ouvrir ou se fermer complètement. Ils sont donc plus rapides pour les applications nécessitant une commande marche/arrêt rapide.

Les robinets-vannes utilisent des tiges multitours, qui nécessitent plusieurs tours complets pour lever ou abaisser la vanne. Cette action plus lente peut aider à prévenir les coups de bélier dans certains systèmes. Mais elle rend les robinets-vannes peu pratiques pour les besoins d'isolation rapide.

Les deux types de vannes peuvent fonctionner à l'aide de poignées manuelles, d'engrenages ou d'actionneurs. Les capacités d'automatisation sont donc similaires.

Facteurs de performance

Les robinets à tournant conique et les robinets-vannes diffèrent également dans divers domaines de performance :

- Traitement de la pression - Les robinets-vannes conviennent aux pressions plus élevées, tandis que les robinets à tournant conique conviennent aux pressions plus faibles.

- Plage de température - Dans la plupart des cas, les températures maximales sont plus élevées pour les robinets-vannes.

- Contrôle de flux - Les robinets à tournant conique permettent d'étrangler le débit. Les robinets-vannes fonctionnent de préférence en position ouverte ou fermée.

- Types de fluides - Les robinets à tournant conique conviennent aux liquides, aux gaz et aux boues. Les robinets-vannes fonctionnent mieux avec les fluides propres.

En position complètement ouverte, les robinets-vannes sont à passage intégral, ce qui signifie qu'ils offrent très peu de restriction de débit ou de perte de charge. Les robinets à tournant conique ont tendance à avoir une perte légèrement plus importante à travers leurs passages forés.

Quelles sont les applications qui conviennent aux robinets à tournant conique ou aux robinets-vannes ?

En comprenant leurs différences de conception et de performance, nous pouvons mieux adapter ces vannes aux applications appropriées.

Applications du robinet à boisseau conique

Les vannes à clapet fonctionnent bien pour :

- Applications marche/arrêt nécessitant une isolation rapide

- Contrôle du flux d'étranglement

- Systèmes à basse pression

- Fluides et boues corrosifs ou abrasifs

- Cyclisme fréquent

Ils conviennent aux systèmes de traitement de l'eau, de traitement chimique, de produits pharmaceutiques et de fabrication industrielle répondant à ces critères.

Applications des robinets-vannes

Les vannes à guillotine sont bien adaptées pour :

- Isolation des conduites à haute pression

- Perte de charge minimale

- Capacité d'écoulement élevée

- Cyclisme peu fréquent

- Fluides propres comme les gaz et l'eau

Les applications typiques des robinets-vannes comprennent les conduites de vapeur, le traitement des hydrocarbures, les systèmes d'extinction d'incendie et la distribution d'eau.

Quelle est la différence entre l'installation et l'entretien ?

Les deux types de vannes présentent des particularités en matière d'installation et d'entretien.

Facteurs d'installation

Les robinets à tournant conique sont généralement plus compacts que les robinets-vannes. Ainsi, les robinets à tournant conique sont plus compacts que les robinets-vannes. Les robinets à tournant conique conviennent aux applications où l'espace est limité.

Cependant, vous devez tenir compte du rayon de rotation de la béquille. Les robinets-vannes ont besoin de plus d'espace en hauteur sur les modèles à tige montante.

Considérations relatives à l'entretien

Les vannes à clapet ont plus de composants internes exposés au flux de fluide. Ils ont donc tendance à avoir besoin de une inspection et une lubrification plus fréquentes pour éviter le collage et assurer une bonne étanchéité.

Les robinets-vannes ont moins de pièces en contact avec le fluide et leur conception "tout ou rien" limite l'usure. Ils ont donc tendance à offrir une bonne durée de vie et à nécessiter moins de maintenance de routine. Négliger une inspection occasionnelle peut toutefois entraîner des problèmes au fil du temps.

Conclusion : Choisir la meilleure vanne pour votre application

Comme vous pouvez le constater, les robinets à tournant conique et les robinets-vannes ont des conceptions très différentes, adaptées à certaines exigences d'installation, aux conditions du système et aux préférences de fonctionnement.

Pour les tâches de mise en marche et d'arrêt rapides inférieures à 1 000 psi, les robinets à tournant conique sont souvent fiables et offrent un contrôle souple de l'étranglement. Les robinets-vannes supportent des pressions plus élevées mais sont plus lents pour les tâches d'isolation. Il existe également des compromis en matière de maintenance.

En comprenant les caractéristiques de ces vannes, ainsi que les besoins de votre système spécifique, vous pouvez sélectionner la meilleure option en toute confiance. Vous êtes ainsi assuré d'obtenir une vanne offrant la sécurité, les performances et la durée de vie exigées par votre application.

Le choix de la bonne vanne est un élément essentiel du fonctionnement efficace du système. Prenez donc le temps de bien comparer les robinets à tournant conique et les robinets-vannes lorsque vous étudiez les différentes options. L'effort est récompensé par des années de bon fonctionnement.