Вы когда-нибудь задумывались, как поворотный клапан работают в тех огромных промышленных трубопроводах, которые вы видите?

Дело в том, что поворотные затворы встречаются повсюду. От местных водоочистных сооружений до нефтеперерабатывающих заводов - эти четвертьоборотные клапаны каждый день управляют потоками миллионов галлонов.

Но вот в чем дело...

Большинство людей не имеют ни малейшего представления о том, как на самом деле работают эти хитроумные устройства. И это проблема, если вы работаете в любой отрасли, связанной с системами управления жидкостями.

Сегодня я расскажу вам о том, как работают поворотные затворы, почему они так популярны и что еще нужно знать об этих важнейших промышленных компонентах.

Звучит неплохо? Давайте погрузимся.

Оглавление

- Что такое поворотный клапан?

- Как работает поворотный клапан: Пошаговый процесс эксплуатации

- Ключевые компоненты, благодаря которым все это работает

- Типы дисковых затворов

- Применение в реальном мире

- Преимущества, которые делают их популярными

- Недостатки, которые следует учитывать

- Поиск и устранение неисправностей

- Критерии отбора на 2025 год

- Итоги

Что такое поворотный клапан?

A поворотный клапан это четвертьоборотный вращающийся клапан, регулирующий поток жидкости в трубопроводах.

Подумайте об этом так:

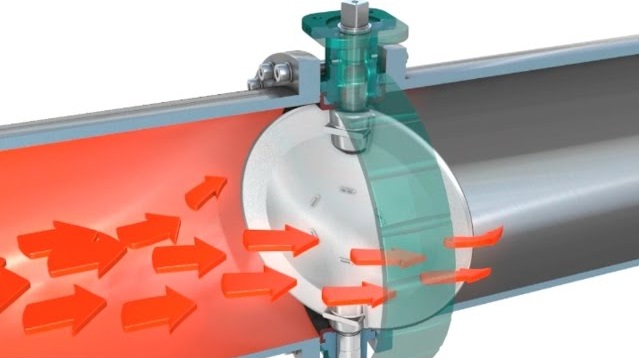

Представьте себе круглый диск ("бабочку"), расположенный внутри трубы. Когда вы поворачиваете этот диск на 90 градусов, он переходит от полного перекрытия потока к практически беспрепятственному прохождению.

Довольно просто, правда?

Название происходит от того, что диск при вращении напоминает крыло бабочки. В отличие от других типов клапанов, которым требуется несколько оборотов для открытия или закрытия, клапанам типа "бабочка" достаточно одного четвертьоборота.

Совет профессионала: Благодаря такому быстрому срабатыванию они идеально подходят для аварийного отключения, где важна скорость.

Как работает поворотный клапан: Пошаговый процесс эксплуатации

Сейчас я расскажу, как именно работает клапан-бабочка:

Шаг 1: Закрытое положение

Когда клапан закрыт, диск сидит на месте. перпендикулярно потоку жидкости.

В этой должности:

- Диск полностью перекрывает проход трубопровода

- Он создает плотное прилегание к седлу клапана

- Через систему проходит ноль жидкости

Это все равно что закрыть дверь в коридоре - ничего не пролезет.

Шаг 2: Последовательность открытия

Вот где происходит волшебство:

Привод (ручная рукоятка, электродвигатель или пневматическая система) начинает вращать шток. Когда диск начинает вращаться, даже небольшое вращение сразу же позволяет начать поток.

Главный вывод? В отличие от задвижек, которые поднимаются прямо вверх, поворотные заслонки вращаются на месте. Это означает, что они невероятно быстро реагируют на управляющие воздействия.

Шаг 3: Полностью открытое положение

При повороте на 90 градусов диск выравнивается параллельно потоку жидкости.

Теперь клапан предлагает:

- Почти беспрепятственное прохождение потока

- Минимальный перепад давления на клапане

- Максимальная пропускная способность трубопровода

Но вот что важно: диск никогда полностью не исчезает из потока. Он всегда создает некоторую турбулентность и перепад давления, даже когда полностью открыт.

Шаг 4: Управление дросселированием

В диапазоне от 0 до 90 градусов вы можете расположить диск под любым углом для регулирование расхода.

Это позволяет операторам:

- Точная настройка расхода

- Давление в системе управления

- Реагируйте на меняющиеся требования к процессу

Итог? Вся операция происходит при повороте всего на 90 градусов. Сравните это с задвижками, которым для полного открытия требуется более 20 полных оборотов.

Ключевые компоненты, благодаря которым все это работает

Чтобы понять, как работают поворотные затворы, необходимо знать их основные части. Позвольте мне рассказать вам о каждом компоненте:

Сборка диска

The Диск - сердце клапана. Эта плоская круглая пластина выполняет всю тяжелую работу по управлению потоком.

Современные диски имеют несколько вариантов дизайна:

- Симметричные диски: Стандартные круглые пластины для общего применения

- Асимметричные диски: S-образные профили, улучшающие характеристики потока

- Усиленные диски: Сверхпрочная конструкция для систем высокого давления

Материал диска полностью зависит от области применения. Чугун отлично подходит для систем водоснабжения, а экзотические сплавы справляются с агрессивными химическими веществами.

Шток и подшипниковая система

The шток соединяет диск с приводомпередавая вращательное усилие по всей системе.

На рынке преобладают две основные конфигурации:

Сквозная конструкция вала: Один вал полностью проходит через корпус клапана. Это обеспечивает максимальную прочность и выравнивание при работе с высокими крутящими моментами.

Конструкция с раздельными валами: Верхний и нижний сегменты вала соединяются с диском отдельно. Это упрощает обслуживание, но снижает общую прочность.

Технология уплотнения

The седло создает критическое уплотнение между диском и корпусом. Три подхода позволяют работать в разных условиях:

Упругие сиденья используйте эластомерные материалы, такие как EPDM или нитрила. Они обеспечивают превосходное уплотнение при минимальном усилии привода, но ограничивают температурный диапазон.

Композитные сиденья сочетают эластомерное уплотнение с жесткими материалами основы. Это повышает долговечность при сохранении хороших характеристик уплотнения.

Металлические сиденья используйте металлические поверхности с прецизионной обработкой для работы в условиях экстремальных температур и давления, когда эластомеры не выдерживают.

Механизмы приводов

Привод обеспечивает управление клапаном. На выбор предлагаются следующие варианты:

- Ручные операторы: Штурвалы или рычаги для местного управления

- Электрические приводы: Точное позиционирование с возможностью дистанционного управления

- Пневматические приводы: Быстрая работа с безотказным пружинным возвратом

- Гидравлические приводы: Максимальный крутящий момент для больших клапанов

Типы дисковых затворов

Не все поворотные затворы созданы одинаковыми. Конструктивные вариации учитывают различные требования к давлению, температуре и применению:

Концентрическая (с нулевым смещением) конструкция

На сайте концентрические поворотные затворыДиск вращается вокруг своей центральной линии. Седло располагается на внутреннем диаметре корпуса клапана.

Лучшее для: Применение при низком давлении, например, в системах отопления, вентиляции и кондиционирования воздуха и водоподготовки, где экономическая эффективность имеет первостепенное значение.

Ограничения: Во время работы диск трется о седло, что со временем приводит к его износу.

Дизайн с двойным смещением

Клапаны с двойным смещением переместите вал за осевую линию диска и сместите его по вертикали. Это создает кулачок, который приподнимает диск от седла сразу после открытия.

Преимущества:

- Значительное снижение износа сидений

- Низкие требования к рабочему моменту

- Подходит для применения при повышенном давлении

Типичные области применения: Переработка нефти и газа, химические заводы, производство электроэнергии.

Дизайн с тройным смещением

Клапаны с тройным смещением добавьте коническую поверхность седла в качестве третьего смещения. Диск соприкасается с седлом только в последние несколько градусов закрытия, устраняя трение на протяжении большей части операции.

Почему это важно: Конструкции с тройным смещением справляются с самыми сложными задачами:

- Паровые системы высокого давления

- Криогенное обслуживание

- Пожаробезопасное применение

- Изоляция критических процессов

Применение в реальном мире

Позвольте мне показать вам, в чем преимущества поворотных затворов в 2025 году:

Системы водоснабжения и водоотведения

Муниципальные водоочистные сооружения в значительной степени полагаются на поворотные затворы для изоляция трубопроводов и контроль потока.

Почему они так хорошо работают здесь:

- Большие размеры (до 120+ дюймов) позволяют выдерживать большие скорости потока

- Коррозионностойкие материалы выдерживают жесткие химические условия воды

- Быстрое управление позволяет оперативно реагировать на изменения в системе

- Более низкая стоимость по сравнению с задвижками или шаровыми кранами

Нефтегазовая промышленность

В нефтехимической промышленности, высокопроизводительные поворотные затворы управлять потоками углеводородов на нефтеперерабатывающих заводах и трубопроводах.

Ключевые требования:

- Пожаробезопасная конструкция в соответствии со стандартами API 607

- Испытания на летучие выбросы в соответствии с ISO 15848

- Номинальное давление до класса 2500

- Экзотические материалы для работы в условиях коррозии

Химическая обработка

В химической промышленности используется поворотные затворы с полимерной футеровкой чтобы справиться с агрессивной средой.

Особые соображения:

- Футеровка из PTFE или PFA устойчива к химическому воздействию

- Санитарные конструкции для пищевой и фармацевтической промышленности

- Совместимость с технологией "чистка на месте" (CIP)

- Материалы, одобренные FDA для контакта с пищевыми продуктами

Производство электроэнергии

Электростанции используют поворотные затворы в системах охлаждения воды, обработки золы и дымовых газов.

Уникальные требования:

- Возможности большого диаметра (обычно 60+ дюймов)

- Автоматизированное управление с помощью пульта дистанционного управления

- Надежная работа в условиях циклической эксплуатации

- Минимальные требования к обслуживанию

Преимущества, которые делают их популярными

Вот почему поворотные затворы занимают доминирующее положение во многих областях применения:

Экономически эффективное решение

Поворотные затворы обычно стоят на 50-70% меньше, чем аналогичные задвижки или шаровые краны. Для крупных трубопроводных проектов это означает значительную экономию.

Компактная установка

Благодаря короткому размеру между торцами поворотные затворы занимают минимум места. Это очень важно при модернизации, когда пространство ограничено.

Быстрая операция

Этот четвертьоборотный механизм позволяет быстро реагировать в чрезвычайных ситуациях. Сравните это с задвижками, которым для полного закрытия требуется несколько минут.

Легкий дизайн

24-дюймовый поворотный затвор весит примерно 500 фунтов. Аналогичная задвижка? 2 000+ фунтов. Это снижает требования к конструктивным опорам и затраты на установку.

Универсальные варианты крепления

Вафельный стиль Клапаны устанавливаются между существующими фланцами. Ушко Конструкции обеспечивают независимое подключение к каждому участку трубопровода. Такая гибкость упрощает монтаж и обслуживание.

Недостатки, которые следует учитывать

Но поворотные затворы не идеальны. Вот их ограничения:

Всегда на пути потока

Даже в полностью открытом состоянии диск создает турбулентность и перепад давления. В системах, требующих полностью беспрепятственного потока (например, в трубопроводах скребок), дроссельные заслонки не подойдут.

Ограниченная точность дросселирования

Хотя поворотные затворы могут регулировать поток, они не так точны, как шаровые или регулирующие клапаны для критически важных приложений управления процессом.

Восприимчивость к кавитации

Высокие перепады давления на частично открытых поворотных заслонках могут вызвать кавитацию при работе с жидкостью, что может привести к повреждению клапана и последующего оборудования.

Температурные ограничения

Эластомерные седла ограничивают максимальную рабочую температуру. Даже конструкции с металлическими седлами сталкиваются с проблемами при температуре выше 1 000°F без применения специальных материалов.

Поиск и устранение неисправностей

Вот как диагностировать и устранить типичные неисправности дроссельной заслонки:

Внешняя утечка

Симптом: Вытекание жидкости из области ствола или суставов тела.

Решение: Замените уплотнения штока или прокладки корпуса. Обычно это требует снятия привода, но не требует полной замены клапана.

Внутренняя утечка

Симптом: Поток продолжается, когда клапан должен быть закрыт.

Возможные причины:

- Повреждение сиденья в результате попадания мусора или износа

- Деформированный диск в результате термоциклирования

- Перекос при неправильной установке

Решение: Осмотрите и замените поврежденные компоненты. Иногда проблема решается только заменой сиденья.

Чрезмерный рабочий момент

Симптом: Клапан становится трудно управляемым или привод борется.

Общие причины:

- Скопление мусора в корпусе клапана

- Коррозия на штоке или диске

- Неправильная установка, приводящая к сцеплению

Решение: Разберите, очистите и осмотрите все компоненты. Замените поврежденные детали и обеспечьте правильное выравнивание при сборке.

Совет профессионала: Регулярное техническое обслуживание предотвращает большинство проблем с крутящим моментом. Простой ежеквартальный осмотр позволяет выявить проблемы на ранней стадии.

Критерии отбора на 2025 год

Выбор подходящего дискового затвора включает в себя несколько ключевых факторов:

Анализ давления и температуры

В качестве отправной точки используйте номинальные значения давления и температуры по ASME B16.34. Но помните, что реальные условия эксплуатации часто включают скачки давления и температуры, выходящие за рамки нормальных условий эксплуатации.

Совместимость материалов

Материалы корпуса от чугуна (для воды) до супердуплексной нержавеющей стали (для агрессивных химических веществ). Всегда обращайтесь к таблицам совместимости и учитывайте антикоррозийные требования при длительной эксплуатации.

Расчеты расхода

Рассчитайте требуемый Cv, исходя из расхода и допустимого перепада давления:

Cv = Q × √(SG/ΔP)

Где Q - расход (GPM), SG - удельный вес, а ΔP - перепад давления (psi).

Требования к приводу в действие

Подумайте, нужно ли вам это:

- Ручное управление для периодического использования

- Электрический привод для дистанционного управления

- Пневматическое управление для быстрого аварийного закрытия

- Гидравлический привод для максимального крутящего момента

Итоги

Как работает дроссельный клапан? Все очень просто: диск поворачивается на 90 градусов, чтобы управлять потоком жидкости в трубопроводе.

Благодаря этому элегантному механизму поворотные затворы стали оптимальным выбором для бесчисленных промышленных применений. От муниципальных систем водоснабжения до морских нефтяных платформ - их сочетание простоты, экономичности и надежности обеспечивает бесперебойную работу процессов по всему миру.

Главный вывод? Понимание принципов работы поворотных затворов поможет вам принимать более правильные решения при выборе, установке и обслуживании клапанов. Независимо от того, выбираете ли вы клапаны для нового проекта или устраняете неполадки в существующих системах, эти знания принесут вам дивиденды в виде повышения производительности и снижения затрат.

Помните: успешное применение клапанов начинается с понимания основ. Освойте эти основы, и вы будете во всеоружии, чтобы справиться даже с самыми сложными ситуациями в области управления жидкостями, которые могут возникнуть на вашем пути.