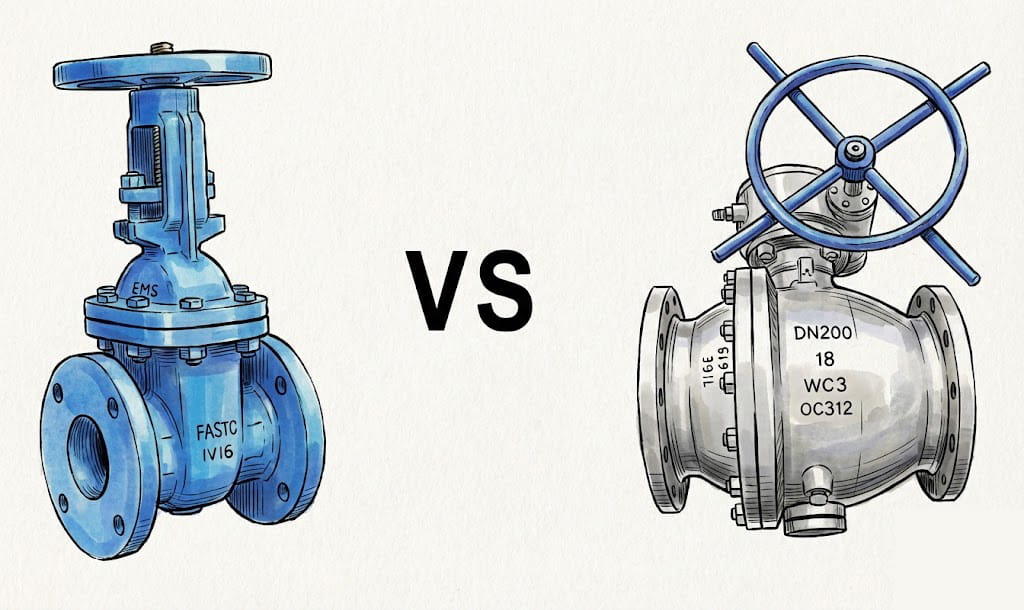

Ball valve vs gate valve – which one should you choose?

Here’s the deal:

If you’re installing valves in your home, industrial facility, or any plumbing system, picking the wrong type can cost you time, money, and a whole lot of headaches.

I’ve seen people waste thousands of dollars on valve replacements because they didn’t understand the key differences between these two valve types.

But don’t worry. As a professional шаровой клапан и производитель задвижек, I’m going to break down everything you need to know.

In this guide, you’ll learn:

- The exact differences between ball valves and gate valves

- When to use each type (with real examples)

- Cost comparisons that’ll save you money

- Common mistakes to avoid

- Step-by-step selection guide

Let’s dive in.

Краткое резюме

- Ball valves are fast, low-maintenance, and provide superior sealing — best for gas lines, compressed air, chemical service, emergency shutoffs, and systems likely to be automated.

- Gate valves suit large-diameter mains, slurry service, high-temperature steam, and throttling applications where slower operation is acceptable and cost matters.

- Main risks: ball valves can cause water hammer and are poor for throttling; gate valves are slow, require more maintenance, and may leak.

- Use the provided step-by-step selection checklist (application, priorities, codes, future needs, total cost) and follow installation/maintenance tips to avoid common costly mistakes.

What’s The Real Difference Between Ball Valves and Gate Valves?

Think of it this way:

A шаровой клапан is like a light switch. Quick on, quick off. It uses a rotating ball with a hole through it to control flow.

A задвижка is more like a garage door. It slowly raises and lowers a metal gate to start or stop the flow.

But here’s where it gets interesting:

These different mechanisms create HUGE differences in how these valves perform.

For example, I recently helped a manufacturing plant switch from gate valves to ball valves on their compressed air lines. The result? They cut their maintenance costs by 47% in just one year.

(More on that later.)

Ball Valves: The Quarter-Turn Champions

Ball valves are the speed demons of the valve world.

Почему?

Because they only need a 90-degree turn to go from fully open to completely closed.

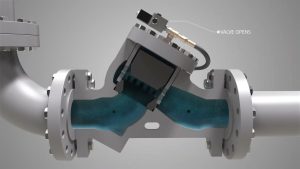

How Ball Valves Actually Work

Here’s what happens inside a ball valve:

- A hollow ball sits inside the valve body

- When the handle is parallel to the pipe, the hole aligns with the flow

- Turn the handle 90 degrees, and the solid part of the ball blocks everything

Просто, правда?

That’s the beauty of it.

Совет профессионала: You can tell if a ball valve is open just by looking at the handle. Parallel = open. Perpendicular = closed.

The Good Stuff About Ball Valves

Let me share what makes ball valves awesome:

Lightning-fast operation – Remember that 90-degree turn? It means you can shut off flow in literally one second.

Rock-solid sealing – Ball valves create what we call a “bubble-tight” seal. Perfect for gas lines where even tiny leaks are dangerous.

Низкие расходы – I’ve seen ball valves run for 10+ years without any service. Try that with a gate valve.

Компактная конструкция – They take up way less space than gate valves of the same size.

The Not-So-Good Stuff

But ball valves aren’t perfect:

Water hammer risk – That super-fast shutoff can create pressure waves in high-pressure systems. (I’ll show you how to avoid this.)

Poor throttling control – Using a ball valve to control flow (not just on/off) will wear it out fast.

Higher upfront cost – Quality ball valves typically cost 20-40% more than gate valves.

Gate Valves: The Steady Workhorses

Now let’s talk about gate valves.

These are the valves your grandfather probably used. And there’s a good reason they’re still around.

How Gate Valves Do Their Thing

Gate valves work exactly like they sound:

- A flat metal gate sits inside the valve body

- Turn the handwheel, and the gate rises up

- Keep turning, and it clears the flow path completely

The key difference? This takes multiple turns – usually 10-15 full rotations.

Why People Still Use Gate Valves

Despite being “old school,” gate valves have serious advantages:

Минимальный перепад давления – When fully open, it’s like the valve isn’t even there. The flow path is completely straight.

Better for throttling – Unlike ball valves, you can partially open gate valves without destroying them.

Низкая стоимость – Usually 20-40% cheaper than equivalent ball valves.

No water hammer – That slow opening/closing eliminates pressure surges.

The Downsides You Need to Know

Here’s where gate valves fall short:

Slow operation – Those 15 turns take time. In emergencies, every second counts.

More maintenance – The rising stem and packing glands need regular attention.

Prone to leaks – After a few years, gate valves often develop small leaks around the stem.

Takes up space – That rising stem needs clearance above the valve.

Ball Valve vs Gate Valve: Head-to-Head Comparison

Let’s get into the nitty-gritty with some real data:

Speed of Operation

- Шаровой кран: 1-2 seconds from open to closed

- Задвижка: 30-60 seconds (depending on size)

In one facility I consulted for, switching to ball valves cut their emergency shutdown time from 45 seconds to 3 seconds.

Durability Stats

Based on industry data from 2025:

- Шаровые краны: Average 15-20 years before major maintenance

- Задвижки: Average 5-10 years before stem seal replacement

Cost Analysis

For a typical 2-inch valve:

- Задвижка: $50-150

- Шаровой кран: $75-200

But here’s the thing:

When you factor in maintenance costs over 10 years, ball valves often end up cheaper.

Pressure Drop Comparison

This surprised me when I first learned it:

- Gate valve (fully open): 0.1-0.2 PSI drop

- Ball valve (full port): 0.1-0.3 PSI drop

Basically identical for most applications.

When to Use Ball Valves (With Real Examples)

Based on my experience, here’s when ball valves are your best bet:

1. Natural Gas Lines

Why: That bubble-tight seal is critical for safety. Plus, you need quick shutoff capability in emergencies.

2. Compressed Air Systems

Why: Frequent on/off cycling would destroy a gate valve’s packing in months.

3. Chemical Processing

Why: Many ball valves have PTFE seats that resist aggressive chemicals.

4. Residential Main Shutoffs

Why: When your pipe bursts at 2 AM, you want to shut it off NOW, not in 60 seconds.

5. Fire Protection Systems

Why: Quick operation can literally save lives.

When Gate Valves Make More Sense

Gate valves aren’t dead. Here’s where they shine:

1. Large Water Mains

Why: On 12-inch+ pipes, gate valves are significantly cheaper and work fine for infrequent use.

2. Slurry Applications

Why: The straight-through design handles particles better than ball valves.

3. High-Temperature Steam

Why: Metal-seated gate valves handle extreme heat better than ball valve seats.

4. Throttling Applications

Why: When you need to control flow (not just on/off), gate valves won’t self-destruct.

Распространенные ошибки, которые стоят больших денег

I’ve seen these errors countless times:

Mistake #1: Using Ball Valves for Throttling

One plant tried using ball valves to control flow on their cooling water system. Within 6 months, every valve was leaking.

The fix: Use gate valves or proper control valves for throttling.

Mistake #2: Installing Gate Valves Where Speed Matters

A food processing plant used gate valves on their emergency chemical wash-down system. During an actual emergency, the 45-second closing time caused $50,000 in product loss.

The fix: Always use ball valves where quick action is critical.

Mistake #3: Ignoring Water Hammer

High-pressure systems + ball valves + untrained operators = broken pipes.

The fix: Install water hammer arrestors or train operators to close valves slowly.

My Step-by-Step Valve Selection Process

Here’s exactly how I help clients choose the right valve:

Step 1: Define Your Application

Спросите себя:

- What’s flowing through it? (Water, gas, chemicals, etc.)

- What’s the pressure and temperature?

- How often will it be operated?

Step 2: Determine Your Priorities

Rank these from most to least important:

- Speed of operation

- Надежность уплотнения

- Initial cost

- Требования к техническому обслуживанию

- Ограничения по площади

Step 3: Check Local Codes

Some jurisdictions require specific valve types. For example, many areas mandate ball valves for gas lines.

Step 4: Consider Future Needs

Will you need to automate these valves later? Ball valves are much easier to automate.

Step 5: Calculate Total Cost

Don’t just look at purchase price. Factor in:

- Installation cost

- Expected maintenance

- Energy losses (pressure drop)

- Potential downtime

Advanced Considerations for 2026

The valve industry isn’t standing still. Here’s what’s new:

Технология интеллектуальных клапанов

Новый IoT-enabled valves can report their status, predict maintenance needs, and even operate remotely. Ball valves are leading this trend due to their simple operation.

Инновации в области материалов

Advanced polymers and coatings are extending valve life dramatically. I’m seeing PTFE-coated ball valves lasting 25+ years in aggressive services.

Экологические нормы

Tighter emissions standards are driving demand for better-sealing valves. Ball valves have a clear advantage here.

Installation Tips That Prevent Problems

Whether you choose ball or gate valves, proper installation is crucial:

For Ball Valves:

- Support the pipeline – Ball valves can’t handle pipe stress

- Check flow direction – Some ball valves are directional

- Leave handle clearance – That 90-degree swing needs room

- Consider orientation – Stem horizontal is usually best

For Gate Valves:

- Install upright when possible – Prevents debris accumulation

- Allow stem clearance – Rising stems need space

- Never force closed – Over-tightening damages seats

- Lubricate regularly – Prevents stem binding

Maintenance Schedules That Actually Work

Here’s what I recommend to clients:

Ball Valve Maintenance:

- Ежемесячно: Cycle the valve if it’s normally static

- Ежегодно: Проверьте наличие внешних утечек

- Every 5 years: Consider replacing seats and seals

Gate Valve Maintenance:

- Квартал: Смажьте резьбу штока

- Semi-annually: Check and adjust packing

- Ежегодно: Full operation test

- Каждые 3-5 лет: Repack or replace packing

Making The Final Decision

Итак, шаровой кран против задвижки – which wins?

Here’s the bottom line:

For most modern applications, ball valves are the better choice. They’re more reliable, require less maintenance, and offer better sealing.

But gate valves still have their place, especially in large-diameter, infrequent-use applications where cost is critical.

Мой совет?

When in doubt, go with a ball valve. The higher upfront cost usually pays for itself through reduced maintenance and better reliability.

Remember: The right valve choice depends on YOUR specific situation. Use this guide to evaluate your needs, and you’ll make the right decision.

Now you know exactly how to choose between a шаровой кран против задвижки for any application. The key is matching the valve type to your specific needs rather than just picking the cheapest option.