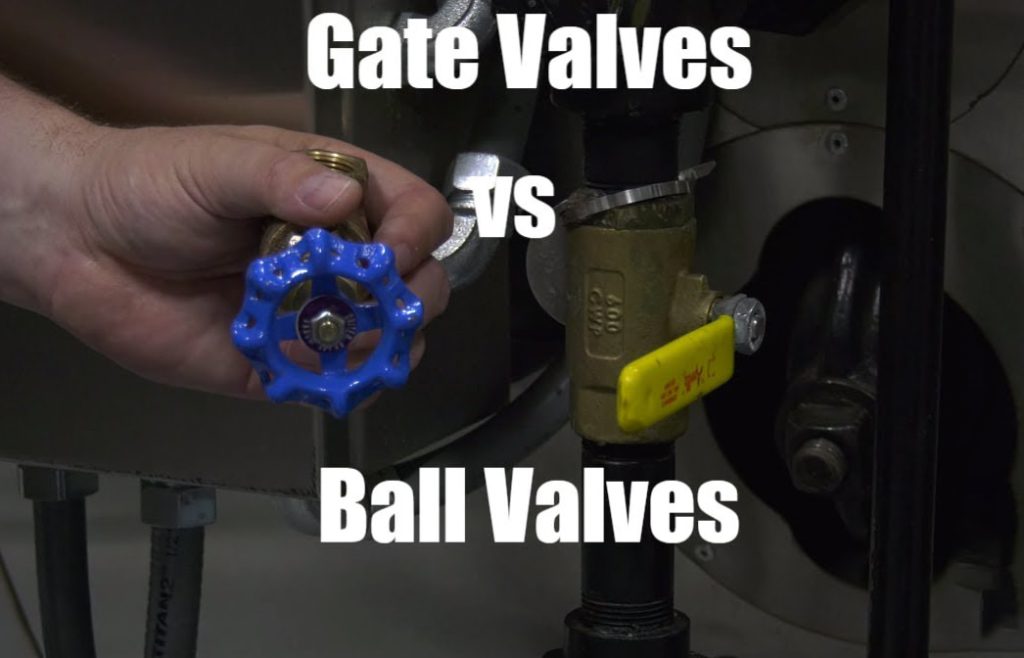

При установке клапанов для жидкостных или газовых систем большинство людей предпочитают шаровые краны. И на это есть веская причина - шаровые краны универсальны, долговечны и обеспечивают надежное перекрытие.

Но шаровые краны не всегда являются лучшим выбором. В некоторых областях применения старые надежные Задвижки это более разумный выбор.

Что такое задвижка?

Прежде чем перейти к причинам выбора задвижек, давайте вкратце расскажем, что это такое и как они работают.

Задвижки состоят из корпуса клапана, в который вставляется затвор. Когда затвор полностью опущен, он прилегает к седлам в корпусе клапана и перекрывает поток. Чтобы открыть клапан, нужно с помощью штока поднять затвор и пропустить через него жидкость.

Задвижки получили свое название благодаря скользящему действию клина, напоминающему ворота. И если шаровые краны работают с помощью простого поворота на 90 градусов, то для открытия/закрытия задвижки требуется повернуть шток на несколько оборотов.

5 ключевых преимуществ задвижек

Теперь, когда вы знаете основы работы задвижек, давайте рассмотрим пять областей, в которых они превосходят шаровые краны.

1. Регулирование потока

Одно из самых больших преимуществ задвижек перед шаровыми кранами заключается в регулировании потока.

Шаровые краны действительно работают только в полностью открытом или полностью закрытом состоянии. Но задвижки позволяют точно регулировать расход путем изменения положения штока. Это позволяет точно контролировать скорость потока жидкости или газа через клапан.

В тех случаях, когда требуется не полностью остановить поток, а задушить его, задвижки - единственный выбор. Подумайте о системах технологических трубопроводов, где требуется точное управление потоком.

2. Полнопроходная конструкция

Задвижки подходят для систем с высокой пропускной способностью, поскольку их отверстие соответствует диаметру трубы при полном открытии. Полнопроходная конструкция исключает ограничения потока или перепады давления, связанные с уменьшением отверстия.

Поэтому, если ваш трубопровод должен обрабатывать большие объемы жидкости, задвижки с меньшей вероятностью будут препятствовать потоку. Шаровые краны могут потребовать значительно большего размера клапана, что увеличивает затраты, чтобы обеспечить беспрепятственный поток от задвижки такого же размера.

3. Возможность дросселирования вязких жидкостей

Дросселирование потока означает частичное закрытие клапана для ограничения - но не полного прекращения - потока. Это бесценный инструмент для управления транспортировкой вязких веществ, таких как осадок сточных вод.

Задвижки дросселируют эти тяжелые жидкости гораздо лучше, чем шаровые краны. Шаровые краны обеспечивают минимальный проход среды перед ее полным перекрытием. Задвижки обеспечивают более широкий контроль над пропуском и предотвращают засоры.

4. Устойчивость к воздействию кавитации

Кавитация - это образование пузырьков пара в областях с низким давлением, которые разрушаются при достижении более высокого давления. Это может привести к серьезному повреждению клапанов и трубопроводов.

Задвижки лучше противостоят разрушительному воздействию кавитации, чем шаровые краны. При высоких скоростях потока мучительный путь через шаровой клапан делает его более склонным к разделению жидкости и кавитации.

5. Низкая первоначальная стоимость

Для арматуры эквивалентного размера задвижки также выигрывают, когда речь идет о первоначальных затратах. Однако при анализе затрат следует учитывать общую стоимость жизненного цикла, а не только начальную цену.

А для поддержания нормального функционирования задвижек часто требуется более регулярное техническое обслуживание. Таким образом, в долгосрочной перспективе эксплуатационные расходы могут уравновесить или даже выиграть у шаровых кранов.

Тем не менее, если при принятии решения приходится ориентироваться на бюджетные ограничения, задвижки станут приятным облегчением. В дальнейшем вы всегда сможете заменить их на более сложные шаровые краны.

Недостатки задвижек

Я сосредоточился в основном на том, почему задвижки выигрывают у шаровых кранов при выполнении определенных функций. Но и шаровые краны имеют ряд преимуществ, которые стоит отметить.

Ограниченные номинальные значения давления

Шаровые краны обычно выдерживают значительно более высокое давление, чем задвижки из тех же материалов и тех же размеров. Поэтому, если расчетное давление в системе превышает пределы задвижек, шаровые краны становятся лучшей альтернативой.

Отсутствие резервного метода герметизации

В большинстве шаровых кранов используются как уплотнения "металл-металл", так и уплотнения из эластомеров. Уплотнения из эластомера защищают металлические компоненты, если седло выше по потоку выходит из строя. Задвижки не имеют такой резервной защиты.

Отсутствие визуальной индикации положения

С помощью шаровых кранов можно с первого взгляда определить, открыт или закрыт клапан. У задвижек нет такой возможности визуального контроля, поскольку затвор находится внутри корпуса клапана. Состояние задвижки можно определить на ощупь по маховику или гайке штока.

Почему кто-то может выбрать задвижку сегодня?

Шаровые краны незаменимы, когда нужно быстро запустить и остановить поток. Именно поэтому их можно встретить на жилых, коммерческих и промышленных объектах. Задвижки выполняют в основном нишевые функции, связанные с регулированием потока.

Возьмем, к примеру, ирригационные системы. Фермеры используют задвижки на концах трубопроводов, чтобы регулировать скорость подачи воды на поля. Они также дросселируют поток, чтобы предотвратить чрезмерный сброс в одной точке выброса.

Для работы с такими веществами, как хлорный газ под давлением, заводы выбирают задвижки, а не шаровые краны. Инженеры завода могут точно откалибровать скорость впрыска хлора, чтобы сбалансировать ее с объемом потока воды ниже по течению.

В любом случае, когда автоматическое управление расходом воды важнее удобства быстрого отключения, предпочтение отдается задвижкам. Их способность точно регулировать проход за счет изменения положения задвижки делает их идеальными для регулирования расхода.

Почему стоит использовать задвижку вместо шарового крана?

Когда точность управления превосходит удобство, задвижки регулируют поток лучше, чем быстро закрывающиеся шаровые краны. Хотя шаровые краны отлично справляются с надежной остановкой потока жидкости и газа, задвижки справляются с дросселированием, требующим более тонких манипуляций с потоком.

Уменьшение их использования не уменьшает возможностей задвижек для выполнения определенных функций. Вы по-прежнему сможете найти их там, где важнее всего точное управление потоком.