Wafer butterfly valves are lightweight, budget-friendly options that work well for low-pressure systems but require full system shutdown for maintenance. Lug butterfly valves cost 15-30% more but allow you to isolate one side for maintenance and handle pressures up to 300 PSI. Choose wafer valves for HVAC and water distribution; choose lug valves for oil & gas, chemical processing, and any application where you can’t afford system shutdowns. The key mistake to avoid: never use wafer valves for dead-end service – they’ll literally fall out.

İşte anlaşma:

If you’re choosing between a wafer and lug butterfly valve, you’re probably wondering which one is right for your system.

And I get it. The wrong choice can lead to maintenance headaches, unexpected shutdowns, and blown budgets.

Bu kılavuzda, bir profesyonel olarak kelebek vana üreticisi, I’ll break down everything you need to know about wafer vs lug butterfly valve selection. Including real-world examples, cost comparisons, and exactly when to use each type.

Hadi içeri dalalım.

What’s the Real Difference Between Wafer and Lug Butterfly Valves?

First, let me clear something up:

Both wafer and lug butterfly valves do the same basic job. They control flow using a rotating disc that turns 90 degrees.

But here’s where things get interesting:

The main difference comes down to how they connect to your pipes. And trust me, this seemingly small detail makes a HUGE difference in how you’ll use them.

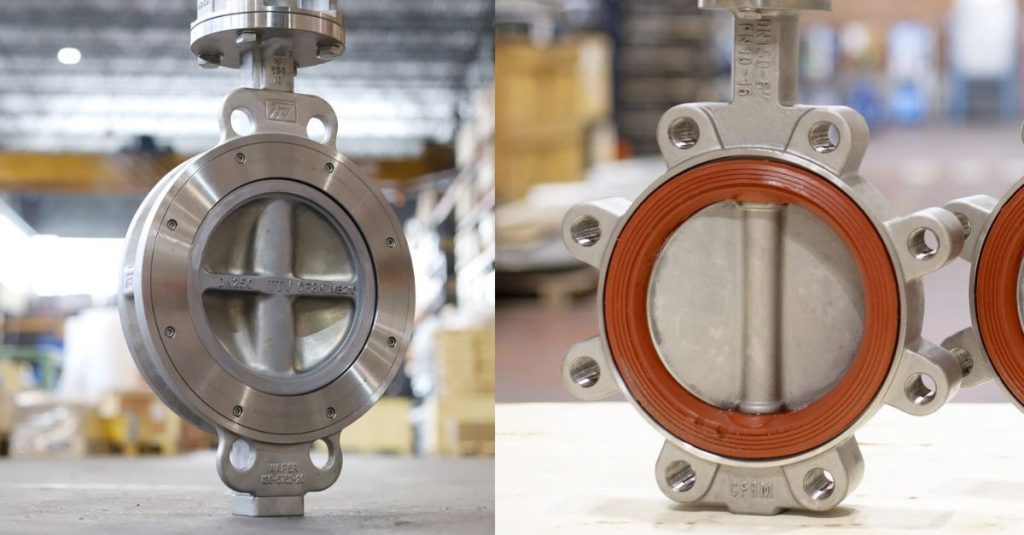

Wafer butterfly valves get sandwiched between two pipe flanges. Think of it like a piece of cheese between two slices of bread. The bolts pass through both flanges and compress the valve in place.

Lug butterfly valves have threaded holes (called lugs) built into the valve body. Each flange bolts directly to the valve. No sandwich effect needed.

Sound simple? It is. But this design difference changes EVERYTHING about how these valves perform in the real world.

The Wafer Butterfly Valve: When Simplicity Wins

Kısa bir hikâye paylaşmama izin verin:

A few years back, I was consulting for a water treatment plant. They needed to replace dozens of valves in their low-pressure distribution system.

Their budget? Tight. Their timeline? Even tighter.

We went with wafer butterfly valves. And it was the perfect choice.

Here’s why wafer valves might be right for you:

The Good Stuff

1. They’re lightweight champions

Wafer valves typically weigh 20-30% less than their lug counterparts. This matters more than you think. Lighter valves mean:

- Daha kolay kurulum

- Less stress on pipe supports

- Lower shipping costs

2. Budget-friendly pricing

In my experience, wafer valves cost about 15-25% less than lug valves. On a project with 50+ valves? Those savings add up fast.

3. Compact design

Wafer valves have the shortest face-to-face dimensions possible. Perfect for tight spaces where every inch counts.

4. Simple installation

No need for precise bolt alignment. Just slide it between the flanges and tighten. A skilled tech can install one in under 20 minutes.

Çok İyi Olmayan Şeyler

But wafer valves aren’t perfect. Here’s what you need to watch out for:

The biggest limitation? You can’t use them for dead-end service. Period.

(Dead-end service = situations where you need to remove downstream piping while maintaining upstream pressure)

Try it, and the valve will literally fall out. I’ve seen it happen. It’s not pretty.

Other drawbacks include:

- Can’t isolate one side for maintenance

- Lower pressure ratings (typically max out at 150-250 PSI)

- Need perfectly aligned flanges

- Require system shutdown for valve replacement

The Lug Butterfly Valve: Built for Flexibility

Now let’s talk about lug valves.

These are the workhorses of industrial applications. And for good reason.

Why Lug Valves Rock

1. True isolation capability

This is the killer feature. With a lug valve, you can:

- Disconnect downstream piping while keeping upstream pressure

- Service equipment without draining the entire system

- Use it as an end-of-line valve

I once worked with a chemical plant that switched from wafer to lug valves. Their maintenance downtime dropped by 40%. Why? They could isolate sections without shutting down the whole process.

2. Higher pressure ratings

Lug valves handle pressure like champs. Most are rated for 250-300 PSI, with some specialty models going even higher.

3. Better for high-vibration environments

Those threaded connections? They create a rock-solid mount that won’t loosen under vibration.

4. Installation flexibility

Each side bolts independently. This means:

- Easier alignment during installation

- Can accommodate slight flange misalignment

- Works with different flange standards on each side

The Trade-offs

Of course, lug valves have their downsides:

- Higher cost (expect to pay 15-30% more)

- Heavier (important for overhead installations)

- Longer installation time (double the bolts = double the work)

- Larger footprint (those lugs add width)

Gofret ve Lug Kelebek Vana

Real-World Application Compare

Let me break this down by industry:

Where Wafer Valves Shine

HVAC Sistemleri

- Low pressure

- Rarely need isolation

- Space constraints in mechanical rooms

- Cost-sensitive

Municipal Water Distribution

- Moderate pressures

- Scheduled maintenance windows

- High volume of valves = cost matters

Yiyecek ve İçecek

- Clean applications

- Regular CIP (Clean-in-Place) cycles

- Sanitary designs available

Swimming Pools & Spas

- Low pressure

- Simple on/off control

- Budget-conscious applications

Where Lug Valves Dominate

Petrol ve Gaz

- High pressures

- Critical isolation requirements

- Safety regulations demand redundancy

- Corrosive media handling

Kimyasal İşleme

- Frequent maintenance needs

- Hazardous materials require secure isolation

- High temperature/pressure combinations

Enerji Üretimi

- Steam and cooling water systems

- Can’t afford full shutdowns

- High cycling applications

Mining & Slurry Service

- Abrasive media wears valves quickly

- Need frequent valve changes

- Isolation prevents process interruption

The Installation Showdown

Here’s exactly how installation differs:

Installing a Wafer Valve (The Quick Version)

- Flanş hizalamasını kontrol edin (critical!)

- Insert valve between flanges

- Insert long bolts through both flanges

- Tighten in a star pattern

- Test operation

Total time: 15-30 minutes

Pro tip: Use a valve centering tool. Misaligned wafer valves leak. Every. Single. Time.

Installing a Lug Valve (The Sturdy Approach)

- Bolt valve to upstream flange

- Align and bolt downstream flange

- No through-bolts needed

- Each side secured independently

Total time: 30-45 minutes

The extra time? Worth it for the flexibility you get.

Cost Comparison: The Real Numbers

Let’s talk money. Here’s what I typically see in 2026:

For a 6-inch valve:

- Wafer: $250-400

- Lug: $350-500

For a 12-inch valve:

- Wafer: $800-1,200

- Lug: $1,000-1,500

Ama şöyle bir şey var:

Initial cost isn’t everything. Consider the total cost of ownership:

Wafer vanalar save money upfront but cost more in downtime during maintenance.

Lug valfler cost more initially but can save thousands in avoided shutdowns.

One client calculated that a single avoided shutdown paid for the upgrade to lug valves across their entire facility.

Making the Right Choice: My Decision Framework

Here’s my simple framework for choosing between wafer vs lug butterfly valve options:

Choose WAFER when:

- Budget is the primary concern

- Space is extremely limited

- System can be shut down for maintenance

- Pressure is below 150 PSI

- You’re doing a one-time installation

Choose LUG when:

- You need isolation capability

- Pressure exceeds 150 PSI

- Maintenance flexibility is crucial

- It’s a critical process application

- The valve will see frequent service

Still unsure? Ask yourself this:

“If this valve fails, can I afford to shut down the entire system?”

If the answer is no, go with a lug valve. The extra cost is cheap insurance.

Kaçınılması Gereken Yaygın Hatalar

Bu hataları sayısız kez gördüm:

Mistake #1: Using wafer valves in vertical pipes

Without bottom support, they can sag and leak. Always add supports or use lug valves.

Mistake #2: Mixing flange standards

Wafer valves need matching flanges. Mixing ANSI with DIN? Recipe for disaster.

Mistake #3: Over-tightening wafer valve bolts

This distorts the body and ruins the seal. Follow torque specs religiously.

Mistake #4: Assuming all lug valves handle dead-end service

Some don’t! Always verify the pressure rating for dead-end applications.

İleri Düzey Değerlendirmeler

For the engineers reading this:

Akış Karakteristikleri

Both valve types use the same disc design, so flow coefficients (Cv) are identical. But installation can affect performance:

- Wafer vanalar with poor centering show 5-10% higher pressure drop

- Lug valfler maintain consistent performance regardless of installation

Automation Readiness

Planning to automate later? Lug valves handle actuator weight and torque better. Their rigid mounting prevents actuator-induced stress on the valve body.

Temperature Cycling

High temperature cycling? Lug valves win. The independent bolting accommodates thermal expansion better than the sandwich-style wafer mounting.

Alt Çizgi

İşte her şey buna bağlı:

Wafer butterfly valves are perfect when you need simple, cost-effective flow control in non-critical applications. They’re the Honda Civic of butterfly valves – reliable, affordable, and they get the job done.

Lug butterfly valves are for when you need flexibility, reliability, and isolation capability. They’re the Toyota Land Cruiser – built tough for challenging conditions and worth the extra investment.

The key is matching the valve to your specific needs. Don’t overspend on lug valves for simple HVAC applications. But don’t cheap out with wafer valves on critical process lines.

Remember: The right valve isn’t the cheapest or the most expensive. It’s the one that keeps your system running smoothly for years to come.

Now you know exactly when to use wafer vs lug butterfly valve designs in your applications. The choice should be crystal clear based on your specific requirements, budget, and maintenance needs.