Hiç merak ettiniz mi bir kelebek vana Kene mi?

Endüstriyel boru tesisatı, HVAC veya su arıtma alanında çalışıyorsanız, muhtemelen her yerde bu çeyrek turlu vanalarla karşılaşmışsınızdır. Ve bunun iyi bir nedeni vardır.

Kelebek vana bileşenleri akışkan akışını inanılmaz bir verimlilikle kontrol etmek için iyi yağlanmış bir makine gibi birlikte çalışır. Ama şöyle bir şey var: çoğu insan bu basit görünen cihazların içinde neler olup bittiğini gerçekten anlamıyor.

Bu bugün değişiyor.

Bu kılavuzda, kelebek vanaları bu kadar etkili kılan her bir bileşeni tek tek inceleyeceğim. Her bir parçanın tam olarak nasıl çalıştığını, hangi malzemelerin en iyi sonucu verdiğini ve bu bileşenlerin özel uygulamanız için neden önemli olduğunu öğreneceksiniz.

Kulağa hoş geliyor mu? Hadi başlayalım.

İçindekiler tablosu

- Kelebek Vana Bileşenleri Nelerdir?

- Kelebek Vana Bileşenleri Analizi

- Gerçekten Önemli Olan Seçim Kriterleri

- Basınç ve Sıcaklık Değerleri

- En İyi Kurulum Uygulamaları

- Sorunları Önleyen Bakım

- Sektöre Göre Yaygın Uygulamalar

- Alt Çizgi

Kelebek Vana Bileşenleri Nelerdir?

İşte anlaşma:

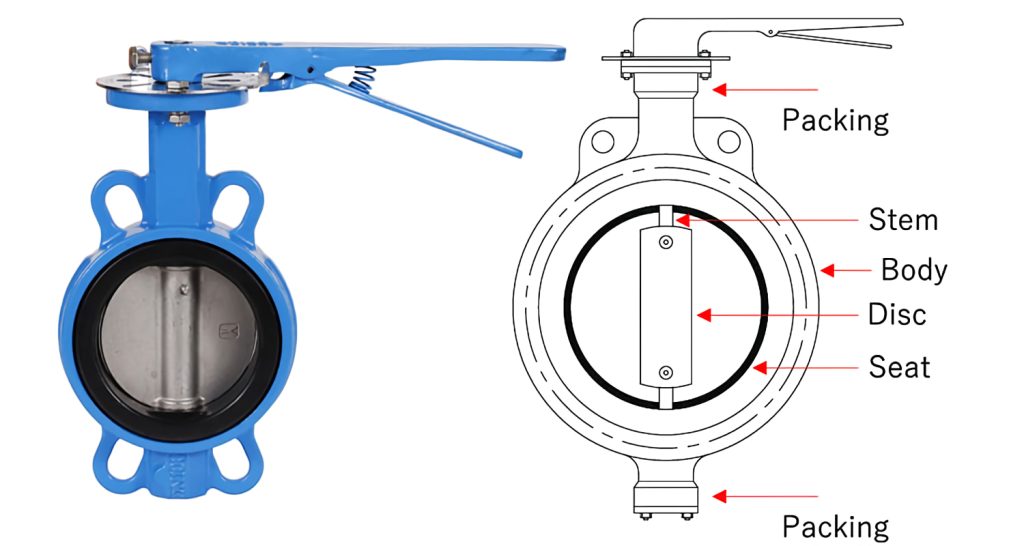

Bir kelebek vana dışarıdan basit görünebilir, ancak aslında uyum içinde çalışan birkaç kritik bileşene sahip sofistike bir mühendislik parçasıdır.

Bunu bir araba motoru gibi düşünün. Kaputu görürsünüz, ancak altında düzinelerce parça her şeyin sorunsuz çalışmasını sağlamak için birlikte çalışır.

Ana kelebek vana bileşenleri şunları içerir:

- Valf gövdesi

- Disk ("kelebek")

- Gövde veya şaft

- Koltuk ve sızdırmazlık sistemi

- Rulmanlar ve burçlar

- Aktüatör mekanizması

Her bileşen sıvı akışını kontrol etmede belirli bir rol oynar. Bir ayrıntıyı gözden kaçırırsanız tüm sisteminiz arızalanabilir.

(Güvenin bana, bunun olduğunu gördüm.)

Kelebek Vana Bileşenleri Analizi

Valf Gövdesi: Sisteminizin Temeli

Valf gövdesi her şeyin başladığı yerdir.

Bu, boru sisteminize bağlanan ve tüm dahili bileşenleri tutan ana muhafazadır. Ancak tüm vana gövdeleri eşit yaratılmamıştır.

Wafer vs. Lug Gövde Stilleri

Burada iki ana seçeneğiniz var:

Wafer tarzı gövdeler bütçe dostu bir seçimdir. Boru flanşları arasına otururlar ve tüm tertibattan geçen uzun cıvatalar kullanırlar. Standart uygulamalarda geri akışı önlemek için mükemmeldir.

Lug tarzı gövdeler birinci sınıf seçenektir. Ayrı cıvata setleriyle doğrudan boru flanşlarına cıvatalamanızı sağlayan dişli uçlara sahiptirler. Bu, diğer tarafı etkilemeden bir tarafın bağlantısını kesebileceğiniz anlamına gelir.

Profesyonel İpucu: Çıkmaz sokakta servis yapıyorsanız veya kolay bakım erişimine ihtiyacınız varsa pabuç stilini tercih edin.

Gerçekten Önemli Olan Gövde Malzemeleri

İşte çoğu insanın yanlış anladığı yer burasıdır:

Malzemeleri performans yerine fiyata göre seçiyorlar.

Yaygın valf gövdesi malzemeleri şunları içerir:

- Dökme demir: Temel su uygulamaları için idealdir

- Eğilebilir Demir: Üstün güç/ağırlık oranı

- Karbon çelik: Petrol ve gaz için standart

- Paslanmaz çelik: Aşındırıcı ortamlar için başvuracağınız yer

Sonuç olarak? Malzemenizi akışkan özellikleriniz, basınç ve sıcaklık gereksinimlerinizle eşleştirin. Başka bir şey sadece sorun yaratır.

Disk: Akış Kontrolünün Kalbi

Şimdi iyi şeylere geliyoruz.

Disk ("kelebek" olarak da adlandırılır) aslında sıvı akışınızı kontrol eden şeydir. Akışa dik olduğunda, kapalısınızdır. Paralel olduğunda ise tamamen açıksınızdır.

Ama ilginç olan şu:

Tüm disk tasarımları aynı şekilde çalışmaz.

Konsantrik ve Eksantrik Tasarımlar

Konsantrik diskler gövde merkez hattından geçer. Basit, uygun maliyetli, temel uygulamalar için mükemmel.

Eksantrik tasarımlar işlerin heyecanlı hale geldiği yerdir:

- Çift eksantrik: İki ofset aşınmayı azaltır ve sızdırmazlığı iyileştirir

- Üçlü eksantrik: Üç ofset, zorlu koşullar için metal-metal sızdırmazlık sağlar

Ben şahsen yüksek performanslı uygulamalar için eksantrik tasarımları öneriyorum. Ekstra maliyet, daha az bakımla kendini amorti ediyor.

Farklı Uygulamalar için Disk Malzemeleri

Disk malzemesi seçiminiz sisteminizi kurabilir ya da bozabilir:

- Paslanmaz çelik: Aşındırıcı sıvıları bir şampiyon gibi idare eder

- Eğilebilir Demir: Su sistemleri için sağlam seçim

- Karbon çelik: Genel endüstriyel kullanım için standart

- PTFE astarlı: Kimyasal işleme için mükemmel

Gövde Tertibatı: Güç İletim Sistemi

Gövde diskinizi dış dünyaya bağlar.

Bunu, aktüatör dönüşünü disk hareketine dönüştüren aktarım sistemi olarak düşünün. Bunu yanlış yaparsanız, valfiniz düzgün çalışmaz.

Tek Parçalı ve İki Parçalı Gövdeler

Tek parça gövdeler birinci sınıf seçimdir. Tek işlenmiş bileşen, zayıf nokta yok, üstün hizalama. Ancak bir şey kırılırsa, her şeyi değiştirirsiniz.

İki parçalı gövdeler daha kolay bakım sunar. Bölümleri tek tek değiştirebilirsiniz, ancak arızalanabilecek potansiyel bağlantı noktalarınız vardır.

Islatılmış ve Islatılmamış Konfigürasyonlar

Çoğu insanın dikkate almadığı bir şey var:

Islatılmış gövdeler doğrudan proses ortamınızla iletişime geçin. Akıttığınız her şeyi kaldırabilecek malzemelere ihtiyacınız var.

Islatılmamış gövdeler gövdeyi ortamınızdan izole etmek için contalar kullanın. Daha karmaşıktır, ancak uygun maliyetli malzemeler kullanmanızı sağlar.

Oturma Sistemleri: Sızdırmazlığın Gerçekleştiği Yer

Valf kapalıyken sızıntıyı önleyen şey yuvanızdır.

Birçok sistemin başarısız olduğu yer de burasıdır.

Yumuşak Koltuk Malzemeleri

Elastomerik koltuklar kabarcık geçirmez sızdırmazlık oluşturmak için deforme olur:

- EPDM: Su arıtma uygulamaları için mükemmel

- NBR: Yağ ve yakıt uygulamalarını idare eder

- PTFE: Kimyasal uyumluluk şampiyonu

Ekstrem Hizmet için Metal Koltuklar

Sıcaklıklar aşırı yükseldiğinde veya aşındırıcı maddelerle uğraştığınızda, metal yuvalar tek seçeneğinizdir.

Paslanmaz çelik koltuklar Yangın güvenliği sağlar ve elastomerik malzemeleri tahrip edebilecek yüksek sıcaklıklarla başa çıkabilir.

Profesyonel İpucu: Koltuk malzemelerinde ucuza kaçmayın. Bir $50 yuva arızası milyon dolarlık bir süreci durdurabilir.

Aktüatör Sistemleri: Her Şeyin Çalışmasını Sağlamak

Aktüatörünüz aslında vanayı çalıştıran şeydir.

Ve her birinin belirli avantajları olan birkaç seçeneğiniz var.

Manuel Aktüatörler

El kolları küçük valfler için harika çalışır. Hızlı çalışma, pozitif konumlandırma ve bunları herhangi bir konumda kilitleyebilirsiniz.

Şanzımanlar daha büyük valfler için ihtiyacınız olan tork çarpımını sağlar. Çalıştırmak daha fazla zaman alır, ancak çok daha yüksek torklarla başa çıkabilirsiniz.

Otomatik Aktüatörler

Uzaktan çalıştırmaya veya otomatik kontrole ihtiyaç duyduğunuzda:

Elektrikli aktüatörler Hassas konumlandırma için limit anahtarlı motorlar kullanın. Uzak konumlar için mükemmeldir.

Pnömatik aktüatörler hızlı çalışma için basınçlı hava kullanın. Hızlı acil kapatmaya ihtiyaç duyduğunuzda harikadır.

Hidrolik aktüatörler en büyük valfler için büyük tork sağlar. Çoğu uygulama için aşırıya kaçar.

Rulmanlar ve Burçlar: İsimsiz Kahramanlar

İşte çoğu insanın görmezden geldiği şey:

Yataklarınız ve burçlarınız valfin ömrü boyunca sorunsuz çalışmasını sağlar.

Bu bileşenler çalışma sırasında sürtünmeyi ve aşınmayı azaltır. Genellikle kendinden yağlama sağlayan bronz veya PTFE malzemelerden yapılırlar.

Rulman kalitesinden ödün verirseniz, sürekli olarak supapları yeniden yapmak zorunda kalırsınız.

Contalar ve O-Ringler: İşleri Sıkı Tutmak

Contalar hareketli parçaların etrafındaki sızıntıyı önler.

PTFE contalar Kimyasallara maruz kalma ve aşırı sıcaklıklarla başa çıkma.

Kauçuk contalar standart su uygulamaları için iyi çalışır.

Grafit contalar yüksek sıcaklıkta servis için başvuracağınız ürünlerdir.

Önemli olan, conta malzemelerini özel çalışma koşullarınıza uygun hale getirmektir.

Gerçekten Önemli Olan Seçim Kriterleri

Artık bileşenleri anladığınıza göre, doğru kombinasyonu nasıl seçersiniz?

İşte benim sistematik yaklaşımım:

İşlev Gereksinimleri

Açma/kapama kontrolü mü yoksa kısma mı yapıyorsunuz? Kısma uygulamaları hassas akış özelliklerine ve düşük basınç düşüşüne ihtiyaç duyar.

Medya Uyumluluğu

Aşındırıcı sıvılar için: PTFE contalı paslanmaz çelik bileşenler

Aşındırıcı ortamlar için: Sertleştirilmiş disk malzemeleri ve metal yuvalar

Yüksek sıcaklıklar için: Metal koltuklar ve grafit paketleme

Basınç ve Sıcaklık Değerleri

Valf değerlerinizi sistem koşullarıyla eşleştirin. Üçlü eksantrik tasarımlar en zorlu koşulların üstesinden gelir.

Akış Katsayısı Hesaplamaları

Vanayı uygun şekilde boyutlandırmak için Cv gereksinimlerinizi hesaplayın. Maksimum akış gereksinimlerini karşıladığınızdan emin olmak için üretici verilerini kullanın.

En İyi Kurulum Uygulamaları

Yanlış monte ederseniz mükemmel bileşenler bile çalışmaz.

İşte önerim:

- Teknik özellikleri doğrulayın sistem gereksinimlerine karşı

- Tüm yüzeyleri temizleyin enkaz hasarını önlemek için

- Flanş hizalamasını kontrol edin (yanlış hizalama disk bağlanmasına neden olur)

- Valfi destekleyin boru yüklerini azaltmak için

- Cıvataları kademeli olarak sıkın uygun sırayla

Profesyonel İpucu: Sorunsuz çalışmasını sağlamak için son sıkma işleminden önce daima vanayı çevirin.

Sorunları Önleyen Bakım

Düzenli bakım, bileşen ömrünü uzatır ve pahalı arızaları önler.

Aylık görevler:

- Düzenli kullanımda değilse vanayı çevrime sokun

- Harici sızıntı olup olmadığını kontrol edin

- Aktüatörün çalıştığını doğrulayın

Yıllık görevler:

- Mil contalarını ve diski yağlayın

- Koltukları aşınma açısından inceleyin

- Rulman durumunu kontrol edin

Bileşenler ne zaman değiştirilmelidir?

- Kabul edilebilir sınırların ötesinde koltuk sızıntısı

- Kök conta sızıntısı

- Çalışma sırasında bağlanma

Sektöre Göre Yaygın Uygulamalar

Farklı sektörler farklı bileşenlere vurgu yapar:

Su arıtma korozyon direnci ve NSF uyumluluğuna odaklanır.

Kimyasal işleme malzeme uyumluluğu ve yangına karşı güvenli tasarımlar gerektirir.

Yağ ve gaz yüksek basınç kapasitesi ve güvenilir sızdırmazlık gerektirir.

HVAC sistemleri hızlı çalışma ve düşük basınç düşüşünü vurgular.

Alt Çizgi

Anlamak kelebek vana bileşenleri sadece teknik bilgi değildir - gerçekten çalışan sistemleri seçmenin, kurmanın ve bakımını yapmanın anahtarıdır.

İşte hatırlamanız gerekenler:

- Malzemeleri özel uygulamanızla eşleştirin

- Koltuklar ve rulmanlar gibi kritik bileşenleri gözden kaçırmayın

- Doğru kurulum çoğu operasyonel sorunu önler

- Düzenli bakım bileşen ömrünü önemli ölçüde uzatır

Vana endüstrisi, her yıl performansı artıran yeni malzemeler ve tasarımlarla gelişmeye devam ediyor. Ancak burada ele aldığım temel konular sabit kalmaktadır.

Nasıl olduğunu anladığınızda kelebek vana bileşenleri birlikte çalışarak, paradan tasarruf eden ve kesinti sürelerini önleyen bilinçli kararlar verebilirsiniz.

Sisteminizin çalışmasını ummak ile çalışacağını bilmek arasındaki fark budur.