Las válvulas de mariposa wafer son opciones ligeras y económicas que funcionan bien en sistemas de baja presión, pero requieren el cierre total del sistema para su mantenimiento. Las válvulas de mariposa de orejetas cuestan 15-30% más, pero permiten aislar un lado para el mantenimiento y soportan presiones de hasta 300 PSI. Elija válvulas wafer para HVAC y distribución de agua; elija válvulas lug para petróleo y gas, procesamiento químico y cualquier aplicación en la que no pueda permitirse paradas del sistema. El error clave que hay que evitar: no utilice nunca válvulas wafer para servicios sin salida; se caerán literalmente.

Este es el trato:

Si está eligiendo entre una válvula de mariposa wafer y una lug, probablemente se esté preguntando cuál es la más adecuada para su sistema.

Y lo entiendo. Una elección equivocada puede provocar problemas de mantenimiento, paradas inesperadas y presupuestos desorbitados.

En esta guía, como profesional fabricante de válvulas de mariposa, Voy a desglosar todo lo que necesita saber sobre la selección de válvulas de mariposa wafer frente a lug. Incluye ejemplos reales, comparaciones de costes y cuándo utilizar exactamente cada tipo.

Vamos a sumergirnos.

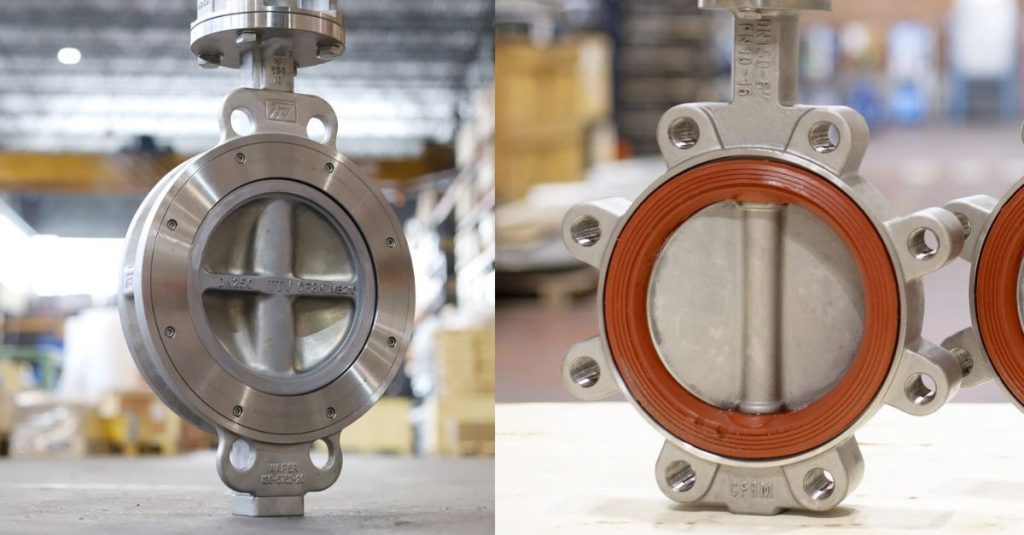

¿Cuál es la diferencia real entre las válvulas de mariposa Wafer y Lug?

En primer lugar, permítanme aclarar algo:

Tanto las válvulas de mariposa de oblea como las de orejeta realizan la misma función básica. Controlan el caudal mediante un disco giratorio que gira 90 grados.

Pero aquí es donde las cosas se ponen interesantes:

En principal diferencia se reduce a cómo se conectan a las tuberías. Y créeme, este detalle aparentemente pequeño marca una diferencia ENORME en el uso que les darás.

Válvulas de mariposa wafer se intercalan entre dos bridas de tubo. Piense que es como un trozo de queso entre dos rebanadas de pan. Los pernos atraviesan ambas bridas y comprimen la válvula en su sitio.

Válvulas de mariposa tienen orificios roscados (denominados orejetas) integrados en el cuerpo de la válvula. Cada brida se atornilla directamente a la válvula. No es necesario el efecto sándwich.

¿Suena sencillo? Pues sí. Pero esta diferencia de diseño cambia TODO sobre el rendimiento de estas válvulas en el mundo real.

La válvula de mariposa wafer: Cuando triunfa la sencillez

Permítanme compartir una breve historia:

Hace unos años, trabajé como consultor para una planta de tratamiento de aguas. Necesitaban sustituir docenas de válvulas de su sistema de distribución de baja presión.

¿Su presupuesto? Ajustado. ¿Su calendario? Aún más ajustado.

Optamos por las válvulas de mariposa wafer. Y fue la elección perfecta.

A continuación le explicamos por qué las válvulas wafer pueden ser adecuadas para usted:

Lo bueno

1. Son campeones ligeros

Las válvulas wafer suelen pesar 20-30% menos que sus homólogas de orejeta. Esto es más importante de lo que cree. Válvulas más ligeras significa:

- Instalación más sencilla

- Menos tensión en los soportes de las tuberías

- Menores gastos de envío

2. Precios asequibles

Según mi experiencia, las válvulas wafer cuestan aproximadamente 15-25% menos que las válvulas lug. ¿En un proyecto con más de 50 válvulas? El ahorro es considerable.

3. 3. Diseño compacto

Las válvulas Wafer tienen las dimensiones cara a cara más cortas posibles. Perfectas para espacios reducidos en los que cada centímetro cuenta.

4. 4. Instalación sencilla

No es necesario alinear los tornillos con precisión. Basta con deslizarlo entre las bridas y apretar. Un técnico experto puede instalar uno en menos de 20 minutos.

Las cosas no tan buenas

Pero las válvulas wafer no son perfectas. Esto es lo que hay que tener en cuenta:

¿La mayor limitación? No puedes utilizarlos para un servicio sin salida. Punto.

(Servicio sin salida = situaciones en las que es necesario eliminar la tubería aguas abajo manteniendo la presión aguas arriba)

Inténtalo y la válvula se caerá literalmente. Lo he visto pasar. No es bonito.

Otros inconvenientes son:

- No se puede aislar un lado para el mantenimiento

- Presiones nominales más bajas (normalmente entre 150 y 250 PSI)

- Necesita bridas perfectamente alineadas

- Exigir la parada del sistema para sustituir la válvula

La válvula de mariposa Lug: Construida para ser flexible

Hablemos ahora de las válvulas de orejetas.

Son los caballos de batalla de las aplicaciones industriales. Y con razón.

Por qué molan las válvulas Lug

1. Capacidad de aislamiento real

Esta es la característica asesina. Con una válvula de orejeta, puedes:

- Desconectar la tubería aguas abajo manteniendo la presión aguas arriba

- Mantenimiento de equipos sin vaciar todo el sistema

- Utilícela como válvula de final de línea

Una vez trabajé en una planta química que cambió las válvulas de oblea por las de orejeta. Su tiempo de inactividad por mantenimiento se redujo en 40%. ¿Por qué? Podían aislar secciones sin parar todo el proceso.

2. Presiones nominales más elevadas

Las válvulas Lug soportan la presión a las mil maravillas. La mayoría están clasificadas para 250-300 PSI, con algunos modelos especiales que van aún más alto.

3. Mejor para entornos de alta vibración

¿Esas conexiones roscadas? Crean un soporte sólido como una roca que no se afloja con las vibraciones.

4. Flexibilidad de instalación

Cada lado se atornilla independientemente. Esto significa:

- Alineación más fácil durante la instalación

- Puede adaptarse a una ligera desalineación de la brida

- Funciona con diferentes estándares de brida en cada lado

Las compensaciones

Por supuesto, las válvulas de orejeta tienen sus inconvenientes:

- Mayor coste (espere pagar 15-30% más)

- Más pesado (importante para instalaciones aéreas)

- Mayor tiempo de instalación (doble de tornillos = doble de trabajo)

- Huella más grande (esos tacos añaden anchura)

Válvula de mariposa Wafer vs Lug

Comparación de aplicaciones reales

Permítanme desglosarlo por sectores:

Dónde brillan las válvulas wafer

Sistemas HVAC

- Baja presión

- Rara vez necesitan aislamiento

- Limitaciones de espacio en las salas de máquinas

- Para tener en cuenta los costes

Distribución municipal de agua

- Presiones moderadas

- Ventanas de mantenimiento programado

- Gran volumen de válvulas = los costes importan

Bebida alimenticia

- Aplicaciones limpias

- PIC ordinario (Limpieza in situ) ciclos

- Diseños sanitarios disponibles

Piscinas y spas

- Baja presión

- Sencillo control de encendido/apagado

- Aplicaciones económicas

Donde dominan las válvulas Lug

Petróleo y gas

- Altas presiones

- Requisitos críticos de aislamiento

- La normativa de seguridad exige redundancia

- Manipulación de medios corrosivos

Procesado químico

- Necesidades de mantenimiento frecuentes

- Los materiales peligrosos requieren un aislamiento seguro

- Combinaciones de alta temperatura y presión

Generación de energía

- Sistemas de vapor y agua de refrigeración

- No podemos permitirnos un cierre total

- Aplicaciones de alto ciclado

Servicio de minería y lodos

- Los medios abrasivos desgastan las válvulas rápidamente

- Necesita cambios frecuentes de válvulas

- El aislamiento evita la interrupción del proceso

El enfrentamiento de la instalación

He aquí exactamente en qué se diferencia la instalación:

Instalación de una válvula Wafer (la versión rápida)

- Comprobar la alineación de la brida (¡crítico!)

- Insertar la válvula entre las bridas

- Inserte pernos largos a través de ambas bridas

- Apriete en forma de estrella

- Operación de prueba

Tiempo total: 15-30 minutos

Consejo profesional: Utilice una herramienta de centrado de válvulas. Las válvulas de oblea mal alineadas tienen fugas. Todas. Cada. Todas. las. veces.

Instalación de una válvula de orejeta (el enfoque robusto)

- Atornillar la válvula a la brida aguas arriba

- Alinear y atornillar la brida aguas abajo

- No necesita tornillos pasantes

- Cada lado asegurado independientemente

Tiempo total: 30-45 minutos

¿El tiempo extra? Merece la pena por la flexibilidad que se obtiene.

Comparación de costes: Las cifras reales

Hablemos de dinero. Esto es lo que veo típicamente en 2026:

Para una válvula de 6 pulgadas:

- Oblea: $250-400

- Lengüeta: $350-500

Para una válvula de 12 pulgadas:

- Oblea: $800-1.200

- Lug: $1.000-1.500

Pero aquí está la cosa:

El coste inicial no lo es todo. Considera el coste total de propiedad:

Válvulas Wafer ahorran dinero por adelantado pero cuestan más en tiempo de inactividad durante el mantenimiento.

Válvulas de retención cuestan más al principio, pero pueden ahorrar miles de euros en paradas evitadas.

Un cliente calculó que una sola parada evitada amortizaba la actualización a válvulas de orejetas en toda su instalación.

Tomar la decisión correcta: Mi marco de decisión

Este es mi marco sencillo para elegir entre las opciones de válvula de mariposa wafer y lug:

Elija WAFER cuando:

- El presupuesto es la principal preocupación

- El espacio es extremadamente limitado

- El sistema puede desconectarse para mantenimiento

- La presión es inferior a 150 PSI

- Estás haciendo una instalación única

Elige LUG cuando:

- Necesita capacidad de aislamiento

- Presión superior a 150 PSI

- La flexibilidad del mantenimiento es crucial

- Es una aplicación crítica del proceso

- La válvula se utilizará con frecuencia

¿Aún no está seguro? Pregúntese lo siguiente:

“Si falla esta válvula, ¿puedo permitirme apagar todo el sistema?”.”

Si la respuesta es negativa, utilice una válvula de orejeta. El coste adicional es un seguro barato.

Errores comunes que hay que evitar

He visto estos errores innumerables veces:

Error #1: Utilizar válvulas wafer en tuberías verticales

Sin soporte inferior, pueden combarse y tener fugas. Añada siempre soportes o utilice válvulas de orejetas.

Error #2: Mezclar normas de bridas

Las válvulas wafer necesitan bridas a juego. ¿Mezclar ANSI con DIN? Receta para el desastre.

Error #3: Apretar demasiado los tornillos de las válvulas wafer

Esto distorsiona el cuerpo y arruina el sello. Siga religiosamente las especificaciones de par de apriete.

Error #4: Asumir que todas las válvulas de orejetas manejan servicios sin salida

Algunos no. Compruebe siempre la presión nominal para aplicaciones sin salida.

Consideraciones avanzadas

Para los ingenieros que lean esto:

Características del flujo

Ambos tipos de válvula utilizan el mismo diseño de disco, por lo que los coeficientes de caudal (Cv) son idénticos. Pero la instalación puede afectar al rendimiento:

- Válvulas Wafer con mal centrado muestran 5-10% mayor caída de presión

- Válvulas de retención mantienen un rendimiento constante independientemente de la instalación

Preparación para la automatización

¿Piensa automatizar más adelante? Las válvulas de orejetas soportan mejor el peso y el par del actuador. Su montaje rígido evita la tensión inducida por el actuador en el cuerpo de la válvula.

Ciclos de temperatura

¿Ciclos de alta temperatura? Las válvulas Lug ganan. El atornillado independiente se adapta mejor a la dilatación térmica que el montaje de obleas tipo sándwich.

Lo esencial

Todo se reduce a esto:

Válvulas de mariposa wafer son perfectas cuando se necesita un control de caudal sencillo y rentable en aplicaciones no críticas. Son el Honda Civic de las válvulas de mariposa: fiables, asequibles y cumplen su cometido.

Válvulas de mariposa son para cuando necesitas flexibilidad, fiabilidad y capacidad de aislamiento. Son el Toyota Land Cruiser: resistentes para condiciones difíciles y merecedores de una inversión extra.

La clave está en adaptar la válvula a sus necesidades específicas. No gaste demasiado en válvulas de orejetas para aplicaciones sencillas de calefacción, ventilación y aire acondicionado. Pero tampoco escatime en válvulas wafer para líneas de proceso críticas.

Recuerde: La válvula correcta no es la más barata ni la más cara. Es la que mantiene su sistema funcionando sin problemas durante años.

Ahora ya sabe exactamente cuándo utilizar diseños de válvulas de mariposa wafer frente a lug en sus aplicaciones. La elección debería estar muy clara en función de sus requisitos específicos, presupuesto y necesidades de mantenimiento.