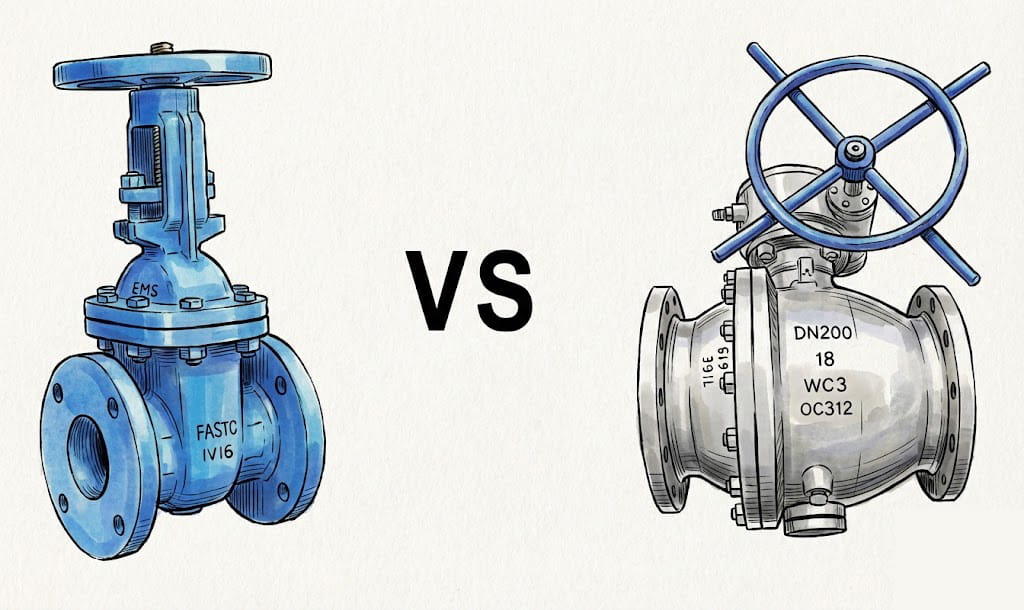

Vanne à bille ou vanne à guillotine - lequel choisir ?

Voici ce qu'il en est :

Si vous installez des vannes dans votre maison, dans une installation industrielle ou dans n'importe quel système de plomberie, le choix d'un mauvais type peut vous faire perdre du temps, de l'argent et beaucoup de maux de tête.

J'ai vu des gens gaspiller des milliers d'euros en remplacements de soupapes parce qu'ils ne comprenaient pas les différences essentielles entre ces deux types de soupapes.

Mais ne vous inquiétez pas. En tant que professionnel vanne à bille et fabricant de robinet-vanneJe vais vous expliquer tout ce que vous devez savoir.

Dans ce guide, vous apprendrez :

- Les différences exactes entre les robinets à boisseau sphérique et les robinets-vannes

- Quand utiliser chaque type (avec des exemples concrets)

- Des comparaisons de coûts qui vous feront économiser de l'argent

- Les erreurs courantes à éviter

- Guide de sélection étape par étape

Plongeons dans le vif du sujet.

Résumé rapide

- Les robinets à tournant sphérique sont rapides, nécessitent peu d'entretien et offrent une étanchéité supérieure. Ils conviennent parfaitement aux conduites de gaz, à l'air comprimé, aux services chimiques, aux fermetures d'urgence et aux systèmes susceptibles d'être automatisés.

- Les robinets-vannes conviennent aux conduites de grand diamètre, aux services de boues, à la vapeur à haute température et aux applications d'étranglement où un fonctionnement plus lent est acceptable et où le coût est important.

- Principaux risques : les robinets à tournant sphérique peuvent provoquer des coups de bélier et ne sont pas adaptés à l'étranglement ; les robinets-vannes sont lents, nécessitent plus d'entretien et peuvent fuir.

- Utilisez la liste de contrôle de sélection étape par étape fournie (application, priorités, codes, besoins futurs, coût total) et suivez les conseils d'installation et d'entretien pour éviter les erreurs coûteuses les plus courantes.

Quelle est la véritable différence entre les robinets à boisseau sphérique et les robinets-vannes ?

Pensez-y de la manière suivante :

A vanne à bille est comme un interrupteur. Il s'allume et s'éteint rapidement. Il utilise une bille rotative percée d'un trou pour contrôler le débit.

A vanne à opercule ressemble davantage à une porte de garage. Il soulève et abaisse lentement un portail métallique pour démarrer ou arrêter l'écoulement.

Mais c'est là que les choses deviennent intéressantes :

Ces différents mécanismes créent d'ENORMES différences dans le fonctionnement de ces valves.

Par exemple, j'ai récemment aidé une usine de fabrication à remplacer les robinets-vannes par des robinets à boisseau sphérique sur ses conduites d'air comprimé. Le résultat ? Elle a réduit ses coûts de maintenance de 47% en un an seulement.

(Nous y reviendrons plus tard).

Vannes à bille : Les champions du quart de tour

Les robinets à tournant sphérique sont les démons de la vitesse dans le monde des robinets.

Pourquoi ?

Parce qu'il suffit d'un virage à 90 degrés pour passer d'une ouverture totale à une fermeture totale.

Fonctionnement des robinets à boisseau sphérique

Voici ce qui se passe à l'intérieur d'un robinet à boisseau sphérique :

- Une bille creuse se trouve à l'intérieur du corps de la vanne

- Lorsque la poignée est parallèle au tuyau, le trou s'aligne sur le flux.

- Tournez la poignée de 90 degrés, et la partie solide de la balle bloque tout

C'est simple, non ?

C'est là toute la beauté de la chose.

Conseil de pro : Il suffit de regarder la poignée pour savoir si un robinet à boisseau sphérique est ouvert. Parallèle = ouvert. Perpendiculaire = fermé.

Les bons côtés des robinets à tournant sphérique

Permettez-moi de vous faire part de ce qui rend les vannes à boisseau sphérique géniales :

Fonctionnement rapide comme l'éclair - Vous vous souvenez de ce virage à 90 degrés ? Cela signifie que vous pouvez interrompre le flux en une seconde.

Une étanchéité à toute épreuve - Les robinets à tournant sphérique créent ce que nous appelons un joint "étanche aux bulles". Ils sont parfaits pour les conduites de gaz où les moindres fuites sont dangereuses.

Faible entretien - J'ai vu des robinets à tournant sphérique fonctionner pendant plus de 10 ans sans aucun entretien. Essayez cela avec un robinet-vanne.

Design compact - Ils prennent beaucoup moins de place que les robinets-vannes de même taille.

Les moins bonnes choses

Mais les robinets à tournant sphérique ne sont pas parfaits :

Risque de coup de bélier - Cette fermeture ultrarapide peut créer des ondes de pression dans les systèmes à haute pression. (Je vous montrerai comment éviter cela).

Mauvais contrôle de l'étranglement - L'utilisation d'un robinet à boisseau sphérique pour contrôler le débit (et pas seulement la marche/arrêt) l'usera rapidement.

Coût initial plus élevé - Les robinets à tournant sphérique de qualité coûtent généralement 20-40% de plus que les robinets-vannes.

Robinets-vannes : Des outils de travail stables

Parlons maintenant des robinets-vannes.

Ce sont les soupapes que votre grand-père utilisait probablement. Et ce n'est pas pour rien qu'elles existent toujours.

Fonctionnement des robinets-vannes

Les robinets-vannes fonctionnent exactement comme leur nom l'indique :

- Un opercule métallique plat se trouve à l'intérieur du corps de la vanne

- Tournez le volant, et le portail se lève

- En continuant à tourner, il libère complètement la voie d'écoulement.

La différence essentielle ? Il faut plusieurs tours - généralement 10 à 15 rotations complètes.

Pourquoi les gens utilisent encore des robinets-vannes

Bien qu'elles soient "de la vieille école", les vannes à guillotine présentent de sérieux avantages :

Perte de charge minimale - Lorsqu'elle est complètement ouverte, c'est comme si la vanne n'existait pas. La voie d'écoulement est complètement droite.

Meilleur pour l'étranglement - Contrairement aux robinets à tournant sphérique, il est possible d'ouvrir partiellement les robinets-vannes sans les détruire.

Coût inférieur - Généralement 20-40% moins chers que les robinets à tournant sphérique équivalents.

Pas de coup de bélier - Cette ouverture/fermeture lente élimine les coups de bélier.

Les inconvénients que vous devez connaître

C'est là que les robinets-vannes ne sont pas à la hauteur :

Fonctionnement lent - Ces 15 tours prennent du temps. Dans les situations d'urgence, chaque seconde compte.

Plus de maintenance - La tige montante et les presse-étoupe doivent faire l'objet d'un entretien régulier.

Risque de fuites - Après quelques années, les robinets-vannes présentent souvent de petites fuites autour de la tige.

Prend de la place - La tige montante a besoin d'un espace libre au-dessus de la soupape.

Robinet à boisseau sphérique ou robinet-vanne : comparaison tête à tête

Entrons dans le vif du sujet avec des données réelles :

Vitesse de fonctionnement

- Robinet à tournant sphérique: 1-2 secondes entre l'ouverture et la fermeture

- Vanne à vanne: 30-60 secondes (en fonction de la taille)

Dans une installation que j'ai consultée, le passage à des vannes à boisseau sphérique a réduit le temps d'arrêt d'urgence de 45 secondes à 3 secondes.

Statistiques de durabilité

Sur la base des données de l'industrie à partir de 2025 :

- Vannes à bille: Moyenne de 15 à 20 ans avant un entretien majeur

- Vannes: Moyenne de 5 à 10 ans avant le remplacement du joint de tige

Analyse des coûts

Pour une vanne typique de 2 pouces :

- Vanne à vanne: $50-150

- Robinet à tournant sphérique: $75-200

Mais voilà :

Si l'on tient compte des coûts de maintenance sur 10 ans, les robinets à tournant sphérique s'avèrent souvent plus économiques.

Comparaison des pertes de charge

Cela m'a surpris lorsque je l'ai appris pour la première fois :

- Vanne (complètement ouverte): Chute de 0,1-0,2 PSI

- Robinet à boisseau sphérique (plein orifice): Chute de 0,1-0,3 PSI

Ils sont fondamentalement identiques pour la plupart des applications.

Quand utiliser les robinets à boisseau sphérique (avec des exemples concrets)

D'après mon expérience, voici les cas où les robinets à boisseau sphérique constituent la meilleure solution :

1. Lignes de gaz naturel

Pourquoi ? Ce joint étanche aux bulles est essentiel pour la sécurité. De plus, vous devez pouvoir l'arrêter rapidement en cas d'urgence.

2. Systèmes d'air comprimé

Pourquoi ? Des cycles marche/arrêt fréquents détruiraient la garniture d'un robinet-vanne en quelques mois.

3. Traitement chimique

Pourquoi ? De nombreux robinets à tournant sphérique ont des sièges en PTFE qui résistent aux produits chimiques agressifs.

4. Fermetures principales résidentielles

Pourquoi ? Lorsque votre canalisation éclate à 2 heures du matin, vous voulez l'arrêter MAINTENANT, pas dans 60 secondes.

5. Systèmes de protection contre l'incendie

Pourquoi ? Une intervention rapide peut littéralement sauver des vies.

Quand les robinets-vannes ont plus de sens

Les robinets-vannes ne sont pas morts. C'est là qu'elles brillent :

1. Grandes conduites d'eau

Pourquoi ? Pour les conduites de plus de 12 pouces, les robinets-vannes sont nettement moins chers et conviennent parfaitement à une utilisation peu fréquente.

2. Applications des boues

Pourquoi ? La conception à passage direct permet de mieux gérer les particules que les vannes à bille.

3. Vapeur à haute température

Pourquoi ? Les robinets-vannes à siège métallique supportent mieux la chaleur extrême que les sièges des robinets à tournant sphérique.

4. Applications d'étranglement

Pourquoi ? Lorsqu'il s'agit de contrôler un débit (et pas seulement de l'activer ou de le désactiver), les robinets-vannes ne s'autodétruisent pas.

Les erreurs courantes qui coûtent cher

J'ai vu ces erreurs un nombre incalculable de fois :

Erreur #1 : Utiliser des robinets à boisseau sphérique pour l'étranglement

Une usine a essayé d'utiliser des vannes à bille pour contrôler le débit de son système d'eau de refroidissement. Au bout de six mois, toutes les vannes fuyaient.

La solution : Utiliser des vannes à guillotine ou des vannes de contrôle appropriées pour l'étranglement.

Erreur #2 : Installer des vannes là où la vitesse est importante

Une usine de transformation alimentaire utilisait des robinets-vannes sur son système de lavage chimique d'urgence. Lors d'une urgence réelle, le temps de fermeture de 45 secondes a entraîné une perte de produit de $50 000.

La solution : Utilisez toujours des robinets à tournant sphérique lorsque la rapidité d'action est essentielle.

Erreur #3 : Ignorer les coups de bélier

Systèmes à haute pression + vannes à bille + opérateurs non formés = tuyaux cassés.

La solution : Installer des dispositifs anti-bélier ou former les opérateurs à fermer les vannes lentement.

Mon processus de sélection des soupapes, étape par étape

Voici exactement comment j'aide mes clients à choisir la bonne valve :

Étape 1 : Définir votre application

Posez-vous la question :

- Qu'est-ce qui y circule ? (Eau, gaz, produits chimiques, etc.)

- Quelles sont la pression et la température ?

- Quelle sera la fréquence d'utilisation de l'appareil ?

Étape 2 : Déterminer vos priorités

Classez-les de la plus importante à la moins importante :

- Vitesse de fonctionnement

- Fiabilité de l'étanchéité

- Coût initial

- Exigences en matière d'entretien

- Contraintes d'espace

Étape 3 : Vérifier les codes locaux

Certaines juridictions exigent des types de vannes spécifiques. Par exemple, de nombreuses régions exigent des robinets à tournant sphérique pour les conduites de gaz.

Étape 4 : Prendre en compte les besoins futurs

Devrez-vous automatiser ces vannes plus tard ? Les robinets à tournant sphérique sont beaucoup plus faciles à automatiser.

Étape 5 : Calculer le coût total

Ne vous contentez pas du prix d'achat. Tenez-en compte :

- Coût de l'installation

- Maintenance prévue

- Pertes d'énergie (chute de pression)

- Temps d'arrêt potentiel

Considérations avancées pour 2026

L'industrie des vannes ne reste pas inactive. Voici les nouveautés :

Technologie des vannes intelligentes

Nouveau compatible avec l'IdO Les vannes à boisseau sphérique peuvent signaler leur état, prévoir les besoins de maintenance et même fonctionner à distance. Les robinets à tournant sphérique sont à la pointe de cette tendance en raison de leur simplicité d'utilisation.

Innovations en matière de matériaux

Les polymères et les revêtements avancés prolongent considérablement la durée de vie des vannes. Je vois des robinets à tournant sphérique revêtus de PTFE qui durent plus de 25 ans dans des services agressifs.

Réglementation environnementale

Les normes d'émission plus strictes stimulent la demande de vannes plus étanches. Les robinets à tournant sphérique ont un net avantage dans ce domaine.

Conseils d'installation pour éviter les problèmes

Qu'il s'agisse de robinets à tournant sphérique ou de robinets-vannes, une installation correcte est cruciale :

Pour les vannes à bille :

- Soutenir la filière - Les robinets à boisseau sphérique ne supportent pas les contraintes de la tuyauterie

- Vérifier le sens d'écoulement - Certains robinets à tournant sphérique sont directionnels

- Dégagement de la poignée de sortie - Cet élan à 90 degrés a besoin d'espace

- Tenir compte de l'orientation - La tige horizontale est généralement la meilleure

Pour les robinets-vannes :

- Installer verticalement lorsque c'est possible - Empêche l'accumulation de débris

- Prévoir un dégagement de la tige - Les tiges montantes ont besoin d'espace

- Ne jamais forcer la fermeture - Un serrage excessif endommage les sièges

- Lubrifier régulièrement - Empêche la fixation des tiges

Des calendriers d'entretien qui fonctionnent

Voici ce que je recommande à mes clients :

Maintenance du robinet à boisseau sphérique :

- Mensuel : Cycle de la vanne si elle est normalement statique

- Annuellement : Vérifier l'absence de fuites externes

- Tous les 5 ans : Envisager le remplacement des sièges et des joints

Maintenance des robinets-vannes :

- Trimestrielle : Lubrifier le filetage de la tige

- Semestriellement : Vérifier et ajuster la garniture

- Annuellement : Test de fonctionnement complet

- Tous les 3 à 5 ans : Réemballer ou remplacer l'emballage

Prendre la décision finale

Ainsi, robinet à tournant sphérique vs robinet-vanne - Qui gagne ?

Voici ce qu'il faut retenir :

Pour la plupart des applications modernes, les robinets à tournant sphérique constituent le meilleur choix. Ils sont plus fiables, nécessitent moins d'entretien et offrent une meilleure étanchéité.

Mais les robinets-vannes ont toujours leur place, en particulier dans les applications de grand diamètre, à usage peu fréquent, où le coût est un facteur critique.

Mon conseil ?

En cas de doute, optez pour un robinet à boisseau sphérique. Le coût initial plus élevé est généralement amorti par une maintenance réduite et une meilleure fiabilité.

N'oubliez pas : Le choix de la bonne valve dépend de VOTRE situation spécifique. Utilisez ce guide pour évaluer vos besoins et vous prendrez la bonne décision.

Vous savez maintenant exactement comment choisir entre un robinet à tournant sphérique vs robinet-vanne pour toutes les applications. L'essentiel est d'adapter le type de vanne à vos besoins spécifiques plutôt que de choisir l'option la moins chère.