Já se perguntou porque é que os seus canos de água fazem aquele som irritante de martelar? Ou porque é que a sua bomba decide de repente fazer horas extraordinárias, gastando energia como um louco?

A questão é a seguinte:

Provavelmente é ar preso no seu sistema. E é exatamente aí que entram as válvulas de ar.

Neste guia, vou mostrar-lhe como um válvula de ar funciona, os diferentes tipos que deve conhecer e como escolher o mais adequado para o seu sistema.

Vamos mergulhar de cabeça.

Índice

- O que causa ar nas tubulações de água?

- Porque é que o ar nos canos é um grande problema

- Como é que uma válvula de ar funciona?

- Os três principais tipos de válvulas de ar

- O mecanismo de flutuação: Onde a magia acontece

- Onde instalar as válvulas de ar (isto é fundamental)

- Aplicações no mundo real

- Problemas e soluções comuns

- Dimensionamento de válvulas de ar (não adivinhe)

- Dicas de manutenção que realmente funcionam

- O futuro da tecnologia de válvulas de ar

- Principais conclusões

O que causa ar nas tubulações de água?

Antes de entrarmos nos pormenores do válvula de ar mecânica, vamos falar sobre a razão pela qual precisa destas coisas em primeiro lugar.

O ar entra nos seus canos de três formas principais:

Condutas vazias: Quando se instala uma conduta pela primeira vez, ela não está tecnicamente vazia. Está cheia de ar. E quando se começa a bombear água através dela, esse ar tem de ir para algum lado.

Ar dissolvido na água: Eis algo que a maioria das pessoas não sabe: a água contém cerca de 2% de ar por volume. À medida que a água flui através do seu sistema, este ar separa-se e acumula-se nos pontos altos.

Equipamento mecânico: As bombas, válvulas e juntas de tubagem podem introduzir ar no seu sistema. Especialmente se os vedantes não forem perfeitos (e sejamos honestos, raramente o são).

E é aqui que as coisas ficam interessantes:

Este ar retido não fica ali parado em silêncio. Ele causa todo o tipo de problemas.

Porque é que o ar nos canos é um grande problema

Já vi sistemas em que o ar preso era a causa:

- Caudais reduzidos (até 30% em alguns casos)

- Martelo hidráulico que literalmente abanou edifícios inteiros

- Tubos corroídos da exposição ao oxigénio

- Leituras incorrectas dos contadores milhares de euros de sobrecustos

- Avarias nas bombas de trabalhar contra bolsas de ar

De facto, um estudo concluiu que a remoção do ar retido pode reduzir os custos de bombagem até 20%.

Isso é dinheiro a sério.

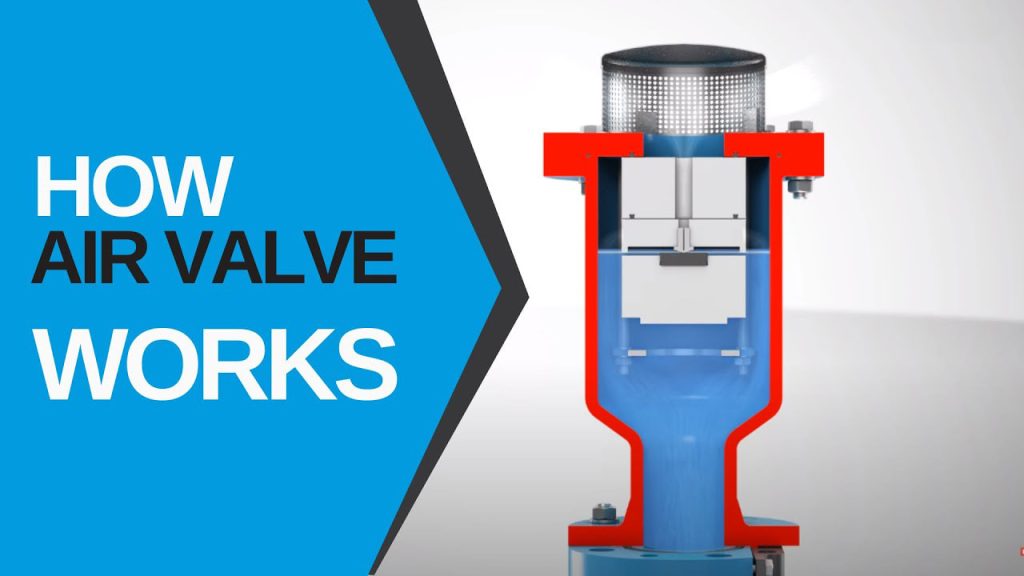

Como é que uma válvula de ar funciona?

Agora o evento principal.

As válvulas de ar funcionam segundo um princípio surpreendentemente simples: flutuabilidade.

O mecanismo básico é o seguinte:

- Quando a água entra na válvula, empurra um flutuador para cima

- A boia veda uma abertura na parte superior da válvula

- Quando o ar se acumula, desloca a água

- O flutuador cai, abrindo a válvula

- Fugas de ar, a água volta a entrar e o ciclo repete-se

Pense nisto como uma válvula de boia da sanita, mas ao contrário.

Muito inteligente, não é?

Mas é aqui que a coisa fica mais sofisticada...

Os três principais tipos de válvulas de ar

Nem todas as válvulas de ar são criadas da mesma forma. Cada tipo serve um objetivo específico:

1. Válvulas de libertação de ar

Estes são os seus cavalos de batalha para o funcionamento normal.

O que fazem: Libertação contínua de pequenas bolsas de ar durante o funcionamento normal do sistema

Tamanho do orifício: Pequena (normalmente 1/16″ a 1/2″)

Melhor para: Eliminação do ar dissolvido que sai da solução

Gosto de pensar neles como a "equipa de manutenção" das válvulas de ar. Estão sempre a trabalhar silenciosamente em segundo plano.

2. Válvulas de ar/vácuo

Estes são os que mais pesam.

O que fazem:

- Ventilar grandes volumes de ar durante o enchimento dos tubos

- Admitir ar durante a drenagem para evitar o colapso do vácuo

Tamanho do orifício: Grande (1″ a 20″ ou mais)

Melhor para: Arranque, paragem e prevenção do colapso da tubagem

Estas válvulas podem movimentar grandes volumes de ar. Estamos a falar de centenas de pés cúbicos por minuto em alguns casos.

3. Válvulas de ar combinadas

Quer o melhor dos dois mundos? É isso que as válvulas combinadas oferecem.

O que fazem: Tudo. Combinam as funções de pequeno e grande orifício

Melhor para: A maioria das aplicações em que se pretende uma gestão completa do ar

Na minha experiência, as válvulas combinadas são frequentemente a escolha mais inteligente. Obtém-se uma proteção abrangente com apenas uma válvula.

O mecanismo de flutuação: Onde a magia acontece

Vamos ser um pouco mais técnicos.

O flutuador dentro de um válvula de ar não é uma boia qualquer. Foi concebida com precisão para:

- Subida com flutuabilidade específica quando rodeado de água

- Largar no momento exato quando o ar está presente

- Vedar perfeitamente sob pressão (por vezes até 300 psi)

Os carros alegóricos modernos são feitos de materiais como:

- Aço inoxidável (para maior durabilidade)

- Polipropileno (para resistência química)

- Compósitos especiais (para aplicações específicas)

E aqui vai uma dica de profissional:

A forma da boia é importante. Os flutuadores esféricos funcionam muito bem para água limpa. Mas para águas residuais? É necessário um flutuador alongado que não fique sujo com detritos.

Onde instalar as válvulas de ar (isto é fundamental)

Localização, localização, localização.

Pode ter o melhor do mundo válvula de armas se estiver no sítio errado? Inútil.

É aqui que precisa deles:

Pontos altos: O ar sobe naturalmente. Instale válvulas nos picos da sua conduta.

Depois das bombas: As bombas podem introduzir ar através da cavitação. Apanhe-a cedo.

Tubagens longas: Instalar válvulas de libertação de ar a cada 800-1000 metros em troços longos.

Medidores de caudal antes e depois: As bolhas de ar prejudicam a precisão. Proteja as suas medições.

Alterações no diâmetro da tubagem: As mudanças de velocidade podem libertar o ar dissolvido.

Um erro que estou sempre a ver?

As pessoas instalam válvulas de ar em locais de difícil acesso. Grande erro. É preciso ser capaz de fazer a manutenção destas coisas.

Aplicações no mundo real

As válvulas de ar não são apenas para as condutas de água. Estão em todo o lado:

- Sistemas de irrigação (evitar a formação de bolhas de ar nos tubos de aspersão)

- Colectores de esgotos (utilizando válvulas de ar especiais para águas residuais)

- Sistemas de proteção contra incêndios (assegurando o fluxo total do tubo quando necessário)

- Processos industriais (desde sistemas de arrefecimento a instalações químicas)

- Sistemas HVAC (eliminação de ar dos circuitos hidrónicos)

Cada aplicação tem os seus próprios requisitos. Os sistemas de esgotos, por exemplo, necessitam de válvulas com caraterísticas anti-entupimento e materiais resistentes à corrosão.

Problemas e soluções comuns

Até as melhores válvulas de ar podem ter problemas. Eis o que deve ser observado:

Problema: Válvula com fuga de água

Solução: Normalmente é um vedante gasto. Substituir o O-ring ou a sede

Problema: A válvula não liberta o ar

Solução: Verificar se existem detritos a bloquear o orifício. Limpar ou substituir

Problema: Descarga de ar constante

Solução: Poderá haver um problema grave de entrada de ar noutro ponto do sistema

Problema: Válvula a tremer ou a vibrar

Solução: Frequentemente causado por dimensionamento incorreto. Recalcular e potencialmente redimensionar

Dimensionamento de válvulas de ar (não adivinhe)

É aqui que muitas pessoas fazem asneira.

Dimensionamento de um válvula de ar não se trata de escolher um que corresponda ao tamanho do seu tubo. Trata-se de calcular:

- Volume de ar durante o enchimento/drenagem

- Pressão de funcionamento

- Caudais de ar necessários

Uma tubagem de 6 polegadas pode necessitar de uma tubagem de 2 polegadas válvula de ar. Ou pode precisar de uma válvula de 4 polegadas. Depende da aplicação específica.

Utilize as tabelas de tamanhos do fabricante. Não adivinhe.

Dicas de manutenção que realmente funcionam

Quer que as suas válvulas de ar durem? Eis o que realmente importa:

- Inspeção anual: Verificar se corrosãodesgaste e funcionamento correto

- Exercitar a válvula: Atuar manualmente para evitar que fique colado

- Limpar o orifício: Mesmo pequenos detritos podem causar problemas

- Verificar o flutuador: Verificar se se move livremente

- Substituir os vedantes de forma pró-ativa: Não esperar por fugas de informação

Já vi válvulas de ar com manutenção correta durarem mais de 20 anos. As negligenciadas? Talvez 5 anos.

O futuro da tecnologia de válvulas de ar

Válvula de ar A tecnologia não está parada. Eis o que está para vir:

- Válvulas inteligentes com sensores IoT para monitorização remota

- Modelos de auto-limpeza para aplicações exigentes

- Materiais avançados para condições extremas

- Alívio de ar/vácuo/pressão integrado combinações

A indústria está a avançar para a manutenção preditiva e a monitorização em tempo real. Coisas muito interessantes.

Principais conclusões

Vamos lá acabar com isto.

Compreensão como válvula de ar obras resume-se a três princípios fundamentais:

- A flutuabilidade acciona o mecanismo - é a física simples a trabalhar para si

- Diferentes tipos servem diferentes objectivos - escolha com base nas suas necessidades

- A instalação e manutenção corretas são cruciais - a localização e os cuidados são importantes

As válvulas de ar podem não ser a parte mais glamorosa de um sistema de tubagem. Mas são absolutamente essenciais para a eficiência, segurança e longevidade.

Se os fizer corretamente, o seu sistema funcionará sem problemas durante anos.

Enganou-se? Bem, é nessa altura que se começam a ouvir aqueles sons de marteladas caras.

O resultado final é o seguinte: as válvulas de ar são um pequeno investimento que evita grandes problemas. E agora que sabe como válvula de ar obrasO sistema de gestão de resíduos é um sistema de gestão de resíduos que permite tomar decisões inteligentes sobre o seu sistema.