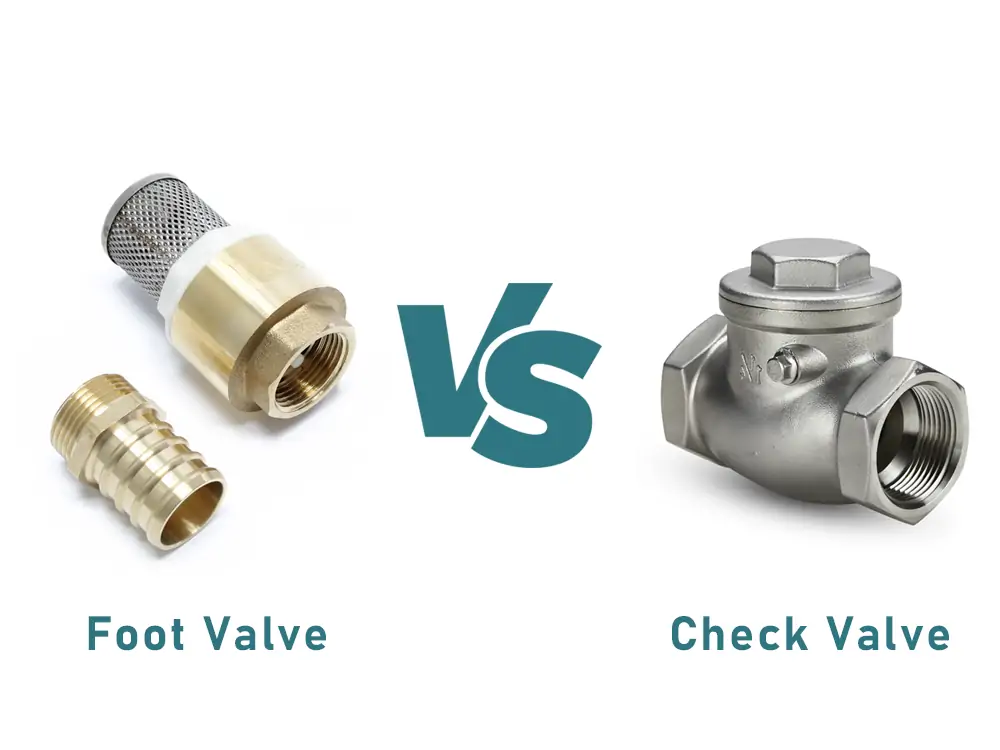

Alguma vez se sentiu confuso sobre o válvula de pé vs válvula de retenção debate?

Não está sozinho.

Recebo perguntas sobre isto a toda a hora de pessoas que trabalham em sistemas de bombas, projectos de canalização e configurações de rega.

A questão é a seguinte:

Embora ambas as válvulas impeçam o refluxo, foram concebidas para tarefas completamente diferentes. E escolher a errada? Bem, isso pode levar a erros muito dispendiosos.

Neste guia, vou explicar tudo o que precisa de saber sobre a válvula de pé vs válvula de retenção comparação. No final, saberá exatamente qual a válvula a utilizar para a sua situação específica.

Parece-lhe bem? Vamos mergulhar.

Índice

- O que é uma válvula de retenção?

- O que é uma válvula de pé?

- As principais diferenças: Válvula de Pé vs Válvula de Retenção

- Quando utilizar uma válvula de pé

- Quando utilizar uma válvula de retenção

- Melhores práticas de instalação

- Requisitos de manutenção

- Erros comuns a evitar

- Guia de seleção de materiais

- Considerações sobre os custos

- Aplicações no mundo real

- Fazer a escolha certa

- Tendências e inovações futuras

- Conclusão

O que é uma válvula de retenção?

Vou começar pelo básico.

A válvula de retenção (também designada por válvula anti-retorno) é bastante simples. Permite o fluxo de fluido numa direção e bloqueia automaticamente o fluxo na direção oposta1.

Pense nisso como uma rua de sentido único para os seus tubos.

Quando a pressão se acumula no lado da entrada, a válvula abre-se. Quando essa pressão cai ou inverte? A válvula fecha-se.

Principais caraterísticas das válvulas de retenção:

- Design de duas portas com rosca em ambos os lados

- Múltiplos mecanismos internos (disco oscilante, disco de elevação, esfera ou diafragma)

- Instalação flexível opções (horizontal ou vertical)

- Funcionamento automático sem controlo manual

- Aplicações versáteis em todos os sistemas de tubagem

A beleza das válvulas de retenção é a sua simplicidade. Não há peças móveis para partir. Não há ligações eléctricas. Apenas engenharia mecânica pura a fazer o seu trabalho.

O que é uma válvula de pé?

Agora é que as coisas ficam interessantes.

A válvula de pé é, na verdade, um tipo especializado de válvula de retenção. Mas tem algumas caraterísticas únicas que a tornam perfeita para aplicações específicas1.

A principal diferença? As válvulas de pé são concebidas para ficarem no fundo das linhas de sucção da bomba, submersas na fonte de fluido.

Principais caraterísticas das válvulas de pé:

- Filtro ou ecrã integrado na entrada

- Conceção de porta única com rosca apenas no lado da saída

- Instalação vertical requisito (direção do fluxo para cima)

- Filtragem de detritos capacidades

- Manutenção principal para sistemas de bombas

Eis o resultado final: Uma válvula de pé é essencialmente uma válvula de retenção com um filtro incorporado.

As principais diferenças: Válvula de Pé vs Válvula de Retenção

Vou explicar isto com uma comparação que tornará tudo muito claro:

| Recurso | Válvula de pé | Válvula de retenção |

|---|---|---|

| Objetivo primário | Evita o refluxo E mantém a escorva da bomba | Evita apenas o refluxo |

| Coador incorporado | Sim, ecrã de filtro integrado | Sem capacidade de filtragem |

| Local de instalação | Fundo da conduta de aspiração, submerso | Em qualquer ponto do sistema de tubagem |

| Enfiamento | Apenas um lado (saída) | Ambos os lados (entrada e saída) |

| Direção do fluxo | Apenas na vertical para cima | Horizontal ou vertical |

| Acesso para manutenção | Desafiante (frequentemente submerso) | Normalmente mais fácil de aceder |

| Custo | Normalmente mais elevado devido ao coador | Custo geralmente mais baixo |

| Tempo de vida | 3-5 anos (condições adversas) | Mais de 5 anos com manutenção adequada |

O visão fundamental aqui? As válvulas de pé resolvem dois problemas de uma só vez: prevenção de refluxo e filtragem de detritos.

Quando utilizar uma válvula de pé

É aqui que as válvulas de pé brilham absolutamente:

Sistemas de bombas de poços

Se estiver a lidar com bombas de poço, as válvulas de pé são muitas vezes inegociáveis. Mantêm a bomba escorvada e filtram os sedimentos que podem danificar os dispendiosos componentes da bomba1.

Aplicações de irrigação

Está a extrair água de lagos, riachos ou fontes de água abertas? O coador incorporado evita que folhas, detritos e outros resíduos entupam o sistema.

Instalações de bombas de drenagem

As inundações na cave já são suficientemente más. Não piore a situação com uma bomba entupida. As válvulas de pé mantêm os detritos afastados, ao mesmo tempo que mantêm a pressão.

Bombas não auto-ferrantes

Qualquer bomba que não se possa auto-ferrar precisa de uma válvula de pé. Ponto final. Sem ela, terá de preparar manualmente a bomba sempre que a ligar.

Dica profissional: Posicione a sua válvula de pé pelo menos 0,75 vezes o diâmetro da válvula acima do fundo da sua fonte de água. Isto minimiza a entrada de sedimentos e reduz o entupimento.

Quando utilizar uma válvula de retenção

As válvulas de retenção são a escolha ideal para:

Prevenção geral de refluxo

Precisa de parar o fluxo inverso algures no seu sistema de tubagem? As válvulas de retenção são perfeitas para proteger as bombas, evitar a contaminação e manter a pressão do sistema.

Sistemas HVAC

Os sistemas de aquecimento e arrefecimento dependem de válvulas de retenção para assegurar a direção correta do fluxo e proteger o equipamento contra picos de pressão.

Sistemas municipais de água

Os sistemas de distribuição de água em grande escala utilizam válvulas de retenção para manter a pressão e evitar a contaminação.

Aplicações industriais

As indústrias de processamento químico, petróleo e gás e de fabrico dependem das válvulas de retenção para operações seguras e eficientes.

Sistemas de proteção contra incêndio

Os sistemas de aspersão necessitam de válvulas de retenção para manter a pressão e garantir que a água flui na direção certa durante as emergências.

A beleza das válvulas de retenção? Versatilidade. Funcionam em quase todos os locais onde é necessário um controlo de fluxo unidirecional.

Melhores práticas de instalação

Permitam-me que partilhe algumas lições duramente aprendidas sobre a instalação correta:

Conselhos para a instalação da válvula de pé:

- Instalar sempre na vertical com direção do fluxo para cima

- Manter a folga adequada do fundo da fonte de água

- Utilizar uma mangueira de sucção de qualidade classificado para a sua aplicação

- Considerar a acessibilidade para manutenção futura

- Verificar os códigos locais para requisitos específicos

Dicas de instalação da válvula de retenção:

- Seguir as setas de direção do fluxo (isto parece óbvio, mas ficaria surpreendido)

- Prestar apoio adequado para evitar o stress nas condutas

- Permitir a expansão térmica em tubagens longas

- Instalar válvulas de fecho em ambos os lados para manutenção

- Considerar as classificações de pressão e limites de temperatura

A questão é a seguinte: Uma má instalação mata mais válvulas do que o desgaste. Demore o tempo que for preciso e faça-o corretamente.

Requisitos de manutenção

Vamos falar sobre como manter estas válvulas a funcionar corretamente.

Manutenção da válvula de pé

As válvulas de pé requerem uma manutenção intensiva. Eis o que está a ver:

- Limpeza regular do coador (a cada 3-6 meses na maioria das aplicações)

- Inspeção da corrosão e fadiga dos materiais

- Controlo da integridade dos selos para evitar fugas

- Controlo dos detritos no fundo da fonte de água

O desafio? A maioria das válvulas de pé estão submersas e são de difícil acesso. Planeie esta situação durante a instalação.

Manutenção da válvula de retenção

As válvulas de retenção são muito mais fáceis de manter:

- Inspecções visuais anuais e testes

- Lubrificação de partes móveis (se aplicável)

- Substituição de vedação quando apresenta desgaste

- Ensaio de pressão para verificar o fecho correto

Conclusão: As válvulas de retenção ganham de longe em termos de conveniência de manutenção.

Erros comuns a evitar

Depois de ver inúmeras instalações ao longo dos anos, eis os maiores erros que vejo:

Utilizar uma válvula de retenção em vez de uma válvula de pé

Este é provavelmente o erro mais caro. A sua bomba perde a pressão, fica seca e queima-se. Ai.

Ignorar a direção do fluxo

A instalação de qualquer válvula ao contrário torna-a inútil. Verifique sempre as setas de fluxo.

Saltar a manutenção regular

Os filtros das válvulas de pé não se limpam sozinhos. Se os negligenciar, verá o desempenho da sua bomba baixar.

Seleção errada do tamanho

As válvulas subdimensionadas criam quedas de pressão. As válvulas sobredimensionadas podem não vedar corretamente. O tamanho é importante.

Má escolha de localização

A acessibilidade para manutenção deve influenciar o local de instalação. Pense no futuro.

Guia de seleção de materiais

O material correto faz toda a diferença:

Para aplicações na água:

- Latão - Bom para temperaturas até 200°F, excelente resistência à corrosão

- Aço inoxidável 316 - Aplicações marítimas, resistência química

- PVC - Económica, leve, boa para pressões moderadas

Para uso industrial:

- Ferro fundido - Aplicações de alta pressão com guarnição em bronze ou aço inoxidável

- CPVC - Processamento químico, temperaturas mais elevadas

- Bronze - Ambientes marinhos, boa durabilidade

Dica profissional: Faça corresponder o material da sua válvula ao seu sistema de tubagem. A mistura de materiais pode provocar corrosão galvânica.

Considerações sobre os custos

Falemos de dinheiro.

Custos iniciais:

- Válvulas de controlo: $35-$600 consoante o tamanho e o material

- Válvulas de pé: Gama semelhante, muitas vezes ligeiramente superior devido ao filtro

- Instalação: $100-$400 mão de obra profissional

Custos do ciclo de vida:

- Válvulas de pé: Substituição a cada 3-5 anos, manutenção mais elevada

- Válvulas de controlo: Mais de 5 anos de vida útil com uma manutenção adequada

O resultado final? Ter em conta o custo total de propriedade e não apenas o preço inicial.

Aplicações no mundo real

Permitam-me que vos dê alguns exemplos concretos:

Estudo de caso 1: Sistema de água de poço

O cliente tinha um poço pouco profundo com uma bomba de jato. Inicialmente, utilizou uma válvula de retenção básica. Resultado? Reabastecimento constante e eventual falha da bomba.

Solução: Mudei para uma válvula de pé com filtro. Problema resolvido.

Estudo de caso 2: Sistema de arrefecimento industrial

A fábrica precisava de prevenção de refluxo no seu circuito de arrefecimento. A válvula de pé teria sido um exagero e criaria uma queda de pressão desnecessária.

Solução: Válvula de retenção de balanço standard. Adaptação perfeita.

Estudo de caso 3: Sistema de irrigação

Operação agrícola que retira água de um lago. A válvula de retenção não conseguia lidar com os detritos. A bomba estava sempre a entupir.

Solução: Válvula de pé com ecrã de filtro grosseiro. Funcionamento limpo desde então.

A lição? O contexto é importante. Não existe uma solução única para todos os casos.

Fazer a escolha certa

Eis o meu quadro de decisão:

Escolha uma válvula de pé quando:

- Instalação no fundo da conduta de aspiração

- A bomba precisa de manter a escorva

- É necessária uma filtragem de detritos

- Captação de água de fontes abertas

- Utilização de bombas não auto-ferrantes

Escolha uma válvula de retenção quando:

- Necessidade de prevenção de refluxo em qualquer ponto do sistema

- A facilidade de acesso para manutenção é importante

- Não é necessária filtragem de detritos

- Necessidade de vários pontos de instalação

- A otimização dos custos é prioritária

A questão fundamental: Está a proteger a linha de sucção de uma bomba ou a impedir o refluxo noutro ponto do seu sistema?

Responda a isso e saberá qual a válvula a escolher.

Tendências e inovações futuras

A indústria das válvulas continua a evoluir. Eis o que estou a prever para 2025:

Tecnologia de válvula inteligente

As válvulas activadas pela IoT com capacidades de monitorização remota estão a tornar-se mais comuns em aplicações industriais.

Materiais melhorados

As novas composições de polímeros oferecem uma melhor resistência química e uma vida útil mais longa.

Designs livres de manutenção

Os mecanismos de auto-limpeza dos filtros estão a reduzir os requisitos de manutenção das válvulas de pé.

Controlo da pressão

Os sensores de pressão integrados ajudam a detetar problemas nas válvulas antes de causarem falhas no sistema.

Conclusão

Aqui tem - a versão completa do válvula de pé vs válvula de retenção comparação.

Lembrar: as válvulas de pé são válvulas de retenção especializadas concebidas para aplicações de sucção de bombas. Evitam o refluxo E filtram os detritos, tornando-os perfeitos para poços, irrigação e sistemas de bombas de drenagem.

As válvulas de retenção, por outro lado, são equipamentos versáteis que impedem o refluxo nos sistemas de tubagem. São mais simples, fáceis de manter e económicas para aplicações gerais.

O resultado final? Adequar a válvula à sua aplicação específica. Considere o local de instalação, os requisitos de manutenção e se necessita de filtragem de detritos.

Quando compreender as diferenças entre as aplicações da válvula de pé e da válvula de retenção, tomará melhores decisões, evitará erros dispendiosos e manterá os seus sistemas a funcionar sem problemas durante muitos anos.

Dica profissional: Em caso de dúvida, consulte um profissional qualificado de canalização ou de sistemas de bombagem. O custo de um aconselhamento especializado é sempre inferior ao custo de escolher a válvula errada.