Inhaltsübersicht

- Was ist ein Absperrventil?

- Wie funktioniert eine Absperrklappe?

- Hauptkomponenten einer Absperrklappe

- Arten von Absperrklappen

- Anschlussarten von Absperrklappen

- Materialien und Temperaturbereiche

- Anwendungen und Anwendungsfälle

- Optionen für die Betätigung

- Vorteile und Nachteile

- Auswahlkriterium

- Wartung und Fehlersuche

- Abschließende Überlegungen

Was ist ein Absperrventil?

Eine Absperrklappe ist eine Vierteldrehklappe, die den Flüssigkeitsdurchfluss mithilfe einer rotierenden Scheibe steuert. Wenn sich die Scheibe um 90 Grad dreht, wird der Durchfluss entweder vollständig geöffnet oder geschlossen. Stellen Sie sich das Ventil wie einen kreisförmigen Schieber vor, der in einem Rohr auf- und zuschwingt.

Ziemlich einfach, oder?

Aber hier ist die Sache:

Obwohl Absperrklappen ein einfaches Design haben, sind sie unglaublich vielseitig. Sie werden überall eingesetzt, von Wasseraufbereitungsanlagen bis hin zu chemischen Verarbeitungsanlagen.

Tatsächlich sind Absperrklappen heute einer der beliebtesten Ventiltypen in industriellen Anwendungen.

Warum?

Denn sie sind kompakt, kostengünstig und super einfach zu bedienen.

In diesem Leitfaden finden Sie alles, was Sie wissen müssen über Absperrklappen. Dazu gehört, wie sie funktionieren, welche Arten es gibt und wann man sie verwenden sollte (und wann nicht).

Lassen Sie uns eintauchen.

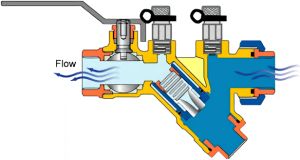

Wie funktioniert eine Absperrklappe?

Das Funktionsprinzip einer Absperrklappe ist eigentlich recht einfach.

Und so funktioniert es:

Eine Absperrklappe hat eine runde Scheibe, die auf einer rotierenden Welle (der sogenannten Spindel) sitzt. Wenn Sie den Griff oder den Stellantrieb drehen, dreht die Spindel die Scheibe.

Wenn die Scheibe parallel zur Strömung steht? Das Ventil ist vollständig geöffnet.

Wenn die Scheibe senkrecht zur Strömung steht? Das Ventil ist vollständig geschlossen.

Und hören Sie sich das an:

Man muss den Griff nur um 90 Grad drehen, um von ganz offen auf ganz geschlossen zu kommen. Deshalb nennt man Absperrklappen auch "Vierteldrehventile".

Aber jetzt wird es interessant:

Sie können die Scheibe auch in verschiedenen Winkeln positionieren, um die Durchflussmenge zu steuern. Sie möchten einen Durchfluss von 50%? Stellen Sie die Scheibe in einem Winkel von etwa 45 Grad auf. Sie brauchen nur ein Rinnsal? Öffnen Sie sie leicht.

Durch diese Drosselungsmöglichkeit sind Absperrklappen sehr vielseitig für Durchflussregelungsanwendungen einsetzbar.

Die Quintessenz?

Absperrklappen bieten eine einfache, zuverlässige Durchflussregelung mit einem Minimum an beweglichen Teilen. Und genau das ist der Grund, warum sie in industriellen Anwendungen so beliebt sind.

Hauptkomponenten einer Absperrklappe

Jede Absperrklappe besteht aus vier Hauptkomponenten, die zusammenwirken. Ich möchte sie für Sie aufschlüsseln:

1. Ventilgehäuse

Der Ventilkörper ist das Hauptgehäuse, das alle internen Teile enthält. Es ist normalerweise aus robusten Materialien wie Gusseisen oder Edelstahl gefertigt.

Das Gehäuse wird an das Rohrleitungssystem angeschlossen und schützt die Scheibe und andere Komponenten vor Beschädigungen.

Es ist sozusagen die Schutzhülle des Ventils.

2. Scheibe

Die Scheibe ist der Star der Show. Es ist der runde Teller, der den Durchfluss steuert.

Wenn Sie die Scheibe drehen, blockiert sie entweder den Strömungsweg (geschlossen) oder richtet sich auf ihn aus (offen).

Hier ist etwas Cooles:

Die Scheibe bleibt immer im Durchflussweg, auch wenn sie vollständig geöffnet ist. Dies führt zu einem leichten Druckabfall, bedeutet aber auch, dass das Ventil sofort auf Regelungsänderungen reagieren kann.

3. Spindel (Welle)

Die Spindel verbindet die Scheibe mit dem externen Griff oder Antrieb. Wenn Sie den Griff drehen, dreht die Spindel die Scheibe.

Die meisten Spindeln führen durch das Ventilgehäuse und sind mit O-Ringen abgedichtet, um Lecks zu vermeiden.

Einige Ventile haben einen einteiligen Schaft. Andere sind zur leichteren Wartung zweiteilig.

4. Sitzplatz

Der Sitz ist die Dichtfläche, gegen die die Scheibe schließt. Er verhindert Leckagen, wenn das Ventil geschlossen ist.

Es gibt zwei Haupttypen von Sitzen:

- Weiche Sitze (aus Gummi oder PTFE) für dichtes Absperren

- Sitze aus Metall für Hochtemperaturanwendungen

Der Sitzwerkstoff bestimmt häufig die Temperatur- und Druckstufen des Ventils.

Arten von Absperrklappen

Nicht alle Absperrklappen sind gleich. Es gibt verschiedene Ausführungen, die jeweils ihre eigenen Vorteile haben.

Ich werde Ihnen die wichtigsten Arten vorstellen:

Nullpunktversetzte (konzentrische) Absperrklappen

Nullpunktverschiebungsventile sind die einfachste Konstruktion. Die Spindel verläuft gerade durch die Mitte der Scheibe.

Diese Ventile haben einen weichen Gummisitz, der sich um den Rand der Scheibe wickelt. Beim Schließen drückt die Scheibe den Sitz zusammen und sorgt so für eine dichte Abdichtung.

Geeignet für:

- Anwendungen mit niedrigem Druck (bis zu 250 PSI)

- Wasser- und Luftversorgung

- Budgetbewusste Projekte

Nachteil: Die Scheibe reibt ständig am Sitz, was mit der Zeit zu Verschleiß führen kann.

Doppelt gekröpfte (Hochleistungs-) Absperrklappen

Doppelt gekröpfte Ventile haben zwei gekröpfte Spindeln:

- Der Vorbau ist von der Mittellinie der Scheibe versetzt

- Der Schaft ist von der Mittellinie des Rohres versetzt

Diese Konstruktion verringert den Sitzverschleiß, da sich die Scheibe beim Öffnen vom Sitz abhebt".

Geeignet für:

- Höhere Drücke und Temperaturen

- Längere Nutzungsdauer erforderlich

- Anwendungen in der chemischen Verarbeitung

Dreifach gekröpfte Absperrklappen

Bei Ventilen mit dreifachem Versatz kommt ein dritter Versatz hinzu: ein winkliger Versatz im Dichtkegel.

Dies ist der Grund, warum dies wichtig ist:

Die Scheibe berührt den Sitz nur im Moment des vollständigen Schließens. Keine Reibung während des Betriebs bedeutet praktisch keinen Verschleiß.

Geeignet für:

- Extreme Temperaturen und Drücke

- Dampfservice

- Leckagefreie Anwendungen

- Kritische Prozesskontrolle

Der Nachteil? Dreifach-Offset-Ventile kosten deutlich mehr als andere Typen.

Anschlussarten von Absperrklappen

Es ist wichtig, wie Sie eine Absperrklappe an Ihr Rohrleitungssystem anschließen. Sehr viel.

Hier sind die wichtigsten Verbindungsarten:

Waffel-Stil

Zwischenflanschklappen passen zwischen zwei Rohrflansche. Lange Bolzen führen durch die Flansche und klemmen die Klappe fest.

Vorteile:

- Kompaktes Design

- Leichtgewicht

- Kosteneffizient

Nachteile:

- Kann nicht für End-of-Line-Service verwendet werden

- Erfordert Abschaltung des Systems zur Wartung

Lug Stil

Lug-Ventile haben rund um das Gehäuse Gewindelöcher. Sie schrauben jeden Rohrflansch direkt an das Ventil.

Großer Vorteil: Sie können eine Seite der Rohrleitung abtrennen, ohne das Ventil zu entfernen.

Dies macht die Ventile perfekt für:

- End-of-Line-Dienst

- Anwendungen, die Isolationsfähigkeit erfordern

- Systeme, die häufig gewartet werden müssen

Geflanscht

Flanschklappen haben auf beiden Seiten erhöhte Flächen, die den Standardrohrflanschen entsprechen.

Wann sie zu verwenden sind:

- Rohre mit großem Durchmesser

- Hochdrucksysteme

- Wenn maximale Stabilität gefragt ist

Stumpfschweißen

Diese Ventile werden direkt in die Rohrleitung geschweißt. Keine Flansche erforderlich.

Perfekt für:

- Festinstallationen

- Hochdruck-/Hochtemperaturbetrieb

- Anwendungen, bei denen Leckagen absolut nicht auftreten können

Der Nachteil? Sie sind für Wartungsarbeiten schwer zu entfernen.

Materialien und Temperaturbereiche

Die bei der Konstruktion von Absperrklappen verwendeten Materialien wirken sich direkt auf Leistung und Lebensdauer aus.

Lassen Sie mich die gängigsten Optionen aufschlüsseln:

Gehäuse Materialien

Gusseisen

- Temperaturbereich: -20°F bis 450°F

- Gut für Wasser- und Luftservice

- Kostengünstige Option

Kohlenstoffstahl

- Temperaturbereich: -20°F bis 800°F

- Hält höhere Drücke aus als Gusseisen

- Häufig in Öl- und Gasanwendungen

Rostfreier Stahl (316/316L)

- Temperaturbereich: -320°F bis 1000°F

- Ausgezeichnete Korrosionsbeständigkeit

- Ideal für die Chemie- und Lebensmittelverarbeitung

Hastelloy/Inconel

- Extreme Temperatur- und Korrosionsbeständigkeit

- Einsatz in hochaggressiven chemischen Dienstleistungen

- Premium-Preispunkt

Sitzmaterialien und ihre Grenzen

Das Sitzmaterial bestimmt häufig die Temperaturklasse des Ventils:

EPDM (Ethylen-Propylen)

- Bereich: -20°F bis 250°F

- Großartig für die Wasserversorgung

- Nicht kompatibel mit Ölen oder Kohlenwasserstoffen

Buna-N (Nitril)

- Bereich: -35°F bis 250°F

- Gut für Öle und Kraftstoffe

- Nicht geeignet für starke Oxidationsmittel

PTFE (Teflon)

- Bereich: -100°F bis 450°F

- Universelle chemische Beständigkeit

- Höhere Kosten, aber längere Lebensdauer

Metall-Sitze

- Bereich: Bis zu 1000°F+

- Einsatz bei extremen Temperaturen

- Kann leichtes Auslaufen haben

Anwendungen und Anwendungsfälle

Absperrklappen sind in vielen verschiedenen Branchen zu finden. Hier sehen Sie, wo sie üblicherweise zu finden sind:

Wasser- und Abwasseraufbereitung

Dies ist wahrscheinlich der größte Markt für Absperrklappen.

Warum?

Weil sie große Durchflussmengen effizient bewältigen und der bei der Wasseraufbereitung üblichen Korrosion widerstehen.

Gemeinsame Anwendungen:

- Rohwasseraufnahme

- Verteilungsnetz

- Isolierung der Pumpe

- Rückspülsysteme

HVAC-Systeme

In der Gebäudetechnik sind Absperrklappen für die Regelung von Kalt- und Warmwasser beliebt.

Sie sind hier perfekt, weil:

- Kompakte Größe passt in enge Maschinenräume

- Schnelle Betätigung zur Temperaturregelung

- Kostengünstig für große Rohrgrößen

Chemische Verarbeitung

Chemieanlagen verwenden Absperrklappen für:

- Kontrolle der Reaktorzufuhr

- Isolierung von Lagertanks

- Korrosiver Einsatz (mit geeigneten Materialien)

Der Schlüssel dazu? Die Auswahl der richtigen Materialien für die chemische Kompatibilität.

Nahrungsmittel und Getränke

Sanitärklappen sind in der Lebensmittelverarbeitung von großer Bedeutung.

Sie bieten:

- Polierte Oberflächen für einfache Reinigung

- FDA-zugelassen Materialien

- CIP-Fähigkeit (Clean-in-Place)

Stromerzeugung

Kraftwerke verwenden Absperrklappen für:

- Kühlwassersysteme

- Dampfkondensat-Service

- Systeme zur Handhabung von Asche

Optionen für die Betätigung

Wie Sie eine Absperrklappe bedienen, hängt von Ihren Anwendungsanforderungen ab.

Hier sind Ihre wichtigsten Optionen:

Manuelle Bedienung

Hebelgriff

- Wird bei kleineren Ventilen verwendet (typischerweise 2-6 Zoll)

- Schnelle Bedienung

- Visuelle Positionsanzeige

Getriebetechniker

- Für größere Ventile oder Anwendungen mit hohen Drehmomenten

- Bietet einen mechanischen Vorteil

- Selbsthemmendes Schneckengetriebe verhindert unerwünschte Bewegungen

Automatisierter Betrieb

Elektrische Stellantriebe

- Präzise Positionskontrolle

- Einfache Integration in Kontrollsysteme

- Erfordert eine Stromquelle

- Am besten geeignet für: Häufiger Betrieb, Fernsteuerungsbedarf

Pneumatische Stellantriebe

- Schnelle Bedienung (typischerweise 1-2 Sekunden)

- Ausfallsichere Optionen verfügbar

- Benötigt Druckluft

- Am besten geeignet für: Sicherheitsanwendungen, häufiges Radfahren

Hydraulische Stellantriebe

- Extrem hohe Drehmomentkapazität

- Reibungsloser Betrieb

- Am besten geeignet für: Große Ventile, Hochdrucksysteme

Vorteile und Nachteile

Lassen Sie uns über die Vor- und Nachteile von Absperrklappen sprechen.

Vorteile

1. Kompakte Bauweise

Absperrklappen benötigen viel weniger Platz als Schieber oder Ventile. Das ist wichtig, wenn Sie enge Rohrleitungspläne entwerfen.

2. Schnelle Bedienung

Die Vierteldrehung ermöglicht ein schnelles Öffnen und Schließen. Perfekt für die Notfallisolierung.

3. Niedriger Druckverlust

Wenn sie vollständig geöffnet sind, schränken Drosselklappen den Durchfluss nur minimal ein.

4. Kostengünstig

Vor allem in größeren Größen kosten Absperrklappen deutlich weniger als andere Ventiltypen.

5. Gute Flusskontrolle

Der Scheibenwinkel bietet eine gute Drosselungsmöglichkeit für viele Anwendungen.

6. Leichtgewicht

Leichtere Installation und weniger Rohrunterstützung als bei schwereren Ventiltypen.

Nachteile

1. Begrenzte Druckstufen

Die meisten Drosselklappen erreichen ihr Maximum bei 250-300 PSI. Sie brauchen einen höheren Druck? Dann müssen Sie einen höheren Preis zahlen.

2. Nicht voll durchgebohrt

Die Scheibe verbleibt immer im Strömungsweg und stellt eine gewisse Einschränkung dar.

3. Beschränkungen der Drosselung

Die Drosselung mit hoher Geschwindigkeit kann die Scheibe und den Sitz beschädigen.

4. Nicht geeignet für Schlämme

Abrasive Materialien können die Dichtungsflächen schnell erodieren.

5. Temperaturbegrenzungen

Weichdichtende Ventile haben Temperaturbeschränkungen aufgrund des Sitzmaterials.

Auswahlkriterium

Die Wahl der richtigen Absperrklappe ist keine Raketenwissenschaft. Aber Sie müssen mehrere Faktoren berücksichtigen:

1. Servicebedingungen

Druck: Vergewissern Sie sich, dass der Nennwert des Ventils Ihren maximalen Systemdruck übersteigt.

Temperatur: Überprüfen Sie den Betriebs- und Umgebungstemperaturbereich

Medien: Beachten Sie die chemische Verträglichkeit mit allen benetzten Materialien

2. Leistungsanforderungen

Fragen Sie sich selbst:

- Brauche ich eine blasendichte Absperrung?

- Wird dieses Ventil gedrosselt oder nur geöffnet/geschlossen?

- Wie oft wird der Zyklus durchgeführt?

3. Einschränkungen bei der Installation

Bedenken Sie:

- Verfügbarer Platz

- Konfiguration der Rohrleitungen

- Zugang zur Wartung erforderlich

- Gewichtsbeschränkungen

4. Kostenerwägungen

Denken Sie daran, dies zu berücksichtigen:

- Ursprünglicher Anschaffungspreis

- Installationskosten

- Langfristige Instandhaltung

- Energiekosten (Druckverlust)

Wartung und Fehlersuche

Die Sache mit den Drosselklappen ist die:

Sie sind ziemlich wartungsarm. Aber "pflegeleicht" bedeutet nicht "wartungsfrei".

Regelmäßige Wartungsaufgaben

Vierteljährlich:

- Das Ventil zirkulieren lassen, um ein Verkleben zu verhindern

- Kontrolle auf externe Leckagen

- Überprüfen Sie den reibungslosen Betrieb

Jährlich:

- Zustand des Sitzes prüfen

- Spindelpackung prüfen

- Bei Bedarf abschmieren

- Testen Sie den Betrieb des Stellantriebs (falls automatisiert)

Allgemeine Probleme und Lösungen

Leckage am Sitz vorbei

- Die Ursache: Abgenutzter oder beschädigter Sitz

- Beheben: Sitz oder gesamtes Ventil austauschen

Schwer bedienbar

- Ursache: Korrosion, Kesselsteinablagerungen oder beschädigte Lager

- Behebung: Reinigen und schmieren, verschlissene Teile ersetzen

Schaftleckage

- Ursache: Verschlissene Packung oder O-Ringe

- Behebung: Packung nachziehen oder Dichtungen ersetzen

Probleme mit dem Aktuator

- Ursache: Verschiedene (Stromausfall, Luftzufuhr, mechanisches Versagen)

- Fix: Fehlersuche auf Basis des Aktuatortyps

Abschließende Überlegungen

Also, Was ist eine Absperrklappe?

Es handelt sich um ein einfaches, aber vielseitiges Durchflussregelgerät, das eine rotierende Scheibe zur Regulierung des Flüssigkeitsdurchflusses verwendet. Bei richtiger Auswahl und Wartung leisten Absperrklappen in unzähligen Anwendungen zuverlässige Dienste.

Der Schlüssel zum Erfolg?

Wir verstehen Ihre spezifischen Anforderungen und wählen den richtigen Ventiltyp, die richtigen Werkstoffe und Merkmale für Ihre Anwendung.

Ganz gleich, ob Sie ein neues System entwerfen oder bestehende Anlagen aufrüsten wollen, Absperrklappen bieten ein hervorragendes Gleichgewicht aus Leistung, Kosten und Zuverlässigkeit.

Denken Sie einfach daran:

Nicht jede Anwendung ist für eine Absperrklappe geeignet. Aber wenn sie passen? Dann sind sie unschlagbar.

Benötigen Sie Hilfe bei der Auswahl der richtigen Absperrklappe für Ihre Anwendung? Berücksichtigen Sie Faktoren wie Druck, Temperatur, Medienkompatibilität und erforderliche Leistung. Und zögern Sie nicht, sich bei kritischen Anwendungen mit Ventilherstellern oder Ingenieuren zu beraten.

Denn letztendlich kann die Wahl des richtigen Ventils den Unterschied ausmachen zwischen einem System, das jahrelang reibungslos funktioniert, und einem, das ständig Kopfschmerzen verursacht.