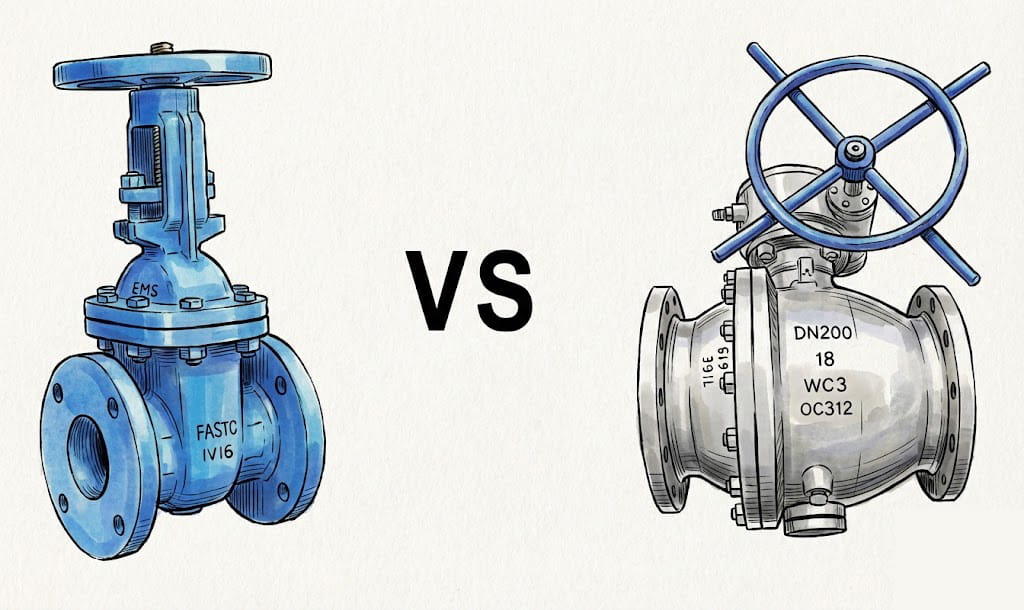

Kugelhahn vs. Schieberventil - Welche sollten Sie wählen?

So sieht es aus:

Wenn Sie Ventile in Ihrem Haus, in einer Industrieanlage oder in einem anderen Sanitärsystem installieren, kann die Wahl des falschen Typs Sie Zeit, Geld und eine Menge Kopfschmerzen kosten.

Ich habe schon erlebt, dass Leute Tausende von Dollar für den Austausch von Ventilen verschwendet haben, weil sie die wesentlichen Unterschiede zwischen diesen beiden Ventiltypen nicht verstanden haben.

Aber keine Sorge. Als Profi Kugelhahn und Hersteller für SchieberventileIch werde alles aufschlüsseln, was Sie wissen müssen.

In diesem Leitfaden erfahren Sie mehr:

- Die genauen Unterschiede zwischen Kugelhähnen und Schieberventilen

- Wann wird welcher Typ verwendet (mit praktischen Beispielen)

- Kostenvergleiche, mit denen Sie Geld sparen können

- Häufig zu vermeidende Fehler

- Schritt-für-Schritt-Leitfaden für die Auswahl

Lassen Sie uns eintauchen.

Kurze Zusammenfassung

- Kugelhähne sind schnell, wartungsarm und bieten eine hervorragende Abdichtung - sie eignen sich am besten für Gasleitungen, Druckluft, chemische Anwendungen, Notabschaltungen und Systeme, die wahrscheinlich automatisiert werden.

- Absperrschieber eignen sich für Rohrleitungen mit großem Durchmesser, Schlammeinsatz, Hochtemperaturdampf und Drosselanwendungen, bei denen ein langsamerer Betrieb akzeptabel ist und Kosten eine Rolle spielen.

- Hauptrisiken: Kugelhähne können Wasserschläge verursachen und eignen sich schlecht zum Drosseln; Schieber sind langsam, erfordern mehr Wartung und können undicht werden.

- Verwenden Sie die mitgelieferte schrittweise Auswahl-Checkliste (Anwendung, Prioritäten, Vorschriften, künftiger Bedarf, Gesamtkosten) und befolgen Sie die Tipps zur Installation/Wartung, um häufige und kostspielige Fehler zu vermeiden.

Was ist der wirkliche Unterschied zwischen Kugelhähnen und Schieberventilen?

Betrachten Sie es einmal so:

A Kugelhahn ist wie ein Lichtschalter. Schnell an, schnell aus. Er verwendet eine rotierende Kugel mit einem Loch, um den Durchfluss zu steuern.

A Absperrschieber ist eher wie ein Garagentor. Es hebt und senkt langsam ein Metalltor, um den Durchfluss zu starten oder zu stoppen.

Aber jetzt wird es interessant:

Diese unterschiedlichen Mechanismen führen zu GROSSEN Unterschieden in der Leistung dieser Ventile.

Vor kurzem habe ich zum Beispiel einem Produktionsbetrieb geholfen, seine Druckluftleitungen von Schieberventilen auf Kugelhähne umzustellen. Das Ergebnis? Sie konnten ihre Wartungskosten in nur einem Jahr um 47% senken.

(Dazu später mehr.)

Kugelhähne: Die Vierteldreh-Champions

Kugelhähne sind die Geschwindigkeitsfanatiker unter den Armaturen.

Warum?

Denn sie brauchen nur eine 90-Grad-Drehung, um von ganz offen auf ganz geschlossen zu wechseln.

Wie funktionieren Kugelhähne eigentlich?

So sieht das Innenleben eines Kugelhahns aus:

- Eine Hohlkugel sitzt im Inneren des Ventilkörpers

- Wenn der Griff parallel zum Rohr steht, richtet sich das Loch mit dem Durchfluss aus.

- Drehen Sie den Griff um 90 Grad, und der feste Teil der Kugel blockiert alles.

Einfach, nicht wahr?

Das ist das Schöne daran.

Profi-Tipp: Ob ein Kugelhahn geöffnet ist, können Sie allein am Griff erkennen. Parallel = offen. Senkrecht = geschlossen.

Das Gute an Kugelhähnen

Lassen Sie mich erklären, was Kugelhähne so besonders macht:

Blitzschneller Betrieb - Erinnern Sie sich an die 90-Grad-Drehung? Das bedeutet, dass Sie den Durchfluss in buchstäblich einer Sekunde unterbrechen können.

Felsenfeste Abdichtung - Kugelhähne sorgen für eine "blasendichte" Abdichtung, wie wir es nennen. Perfekt für Gasleitungen, bei denen selbst winzige Lecks gefährlich sind.

Geringer Wartungsaufwand - Ich habe schon Kugelhähne gesehen, die mehr als 10 Jahre lang ohne jegliche Wartung liefen. Versuchen Sie das mal mit einem Absperrschieber.

Kompaktes Design - Sie benötigen viel weniger Platz als Schieber gleicher Größe.

Die nicht so guten Dinge

Aber Kugelhähne sind nicht perfekt:

Wasserschlagrisiko - Dieses superschnelle Abschalten kann in Hochdrucksystemen Druckwellen erzeugen. (Ich zeige Ihnen, wie Sie das vermeiden können.)

Schlechte Drosselungskontrolle - Die Verwendung eines Kugelventils zur Durchflussregelung (nicht nur zum Ein- und Ausschalten) führt zu einer schnellen Abnutzung des Ventils.

Höhere Anfangskosten - Hochwertige Kugelhähne kosten in der Regel 20-40% mehr als Schieber.

Schieberventile: Die stetigen Arbeitstiere

Lassen Sie uns nun über Absperrschieber sprechen.

Das sind die Ventile, die wahrscheinlich schon Ihr Großvater benutzt hat. Und es gibt einen guten Grund, warum es sie immer noch gibt.

Wie Absperrschieber ihre Aufgabe erfüllen

Absperrschieber funktionieren genau so, wie sie klingen:

- Im Inneren des Ventilgehäuses befindet sich ein flacher Metallschieber

- Drehen Sie das Handrad, und das Tor hebt sich

- Drehen Sie weiter, und der Fließweg wird vollständig frei.

Der entscheidende Unterschied? Es sind mehrere Umdrehungen erforderlich - in der Regel 10-15 volle Umdrehungen.

Warum Menschen immer noch Schieber verwenden

Obwohl sie "altmodisch" sind, haben Schieber ernsthafte Vorteile:

Minimaler Druckverlust - Wenn das Ventil vollständig geöffnet ist, ist es so, als ob es gar nicht vorhanden wäre. Der Durchflussweg ist völlig gerade.

Besser für die Drosselung - Im Gegensatz zu Kugelhähnen können Sie Schieber teilweise öffnen, ohne sie zu zerstören.

Niedrigere Kosten - Normalerweise 20-40% billiger als gleichwertige Kugelhähne.

Kein Wasserschlag - Durch das langsame Öffnen/Schließen werden Druckstöße vermieden.

Die Nachteile, die Sie kennen sollten

Das ist der Punkt, an dem Schieber versagen:

Langsamer Betrieb - Diese 15 Runden brauchen Zeit. In Notfällen zählt jede Sekunde.

Mehr Wartung - Der aufsteigende Stängel und die Stopfbuchsen müssen regelmäßig kontrolliert werden.

Anfällig für Lecks - Nach einigen Jahren entwickeln Schieber oft kleine Lecks im Bereich der Spindel.

Nimmt Platz weg - Der aufsteigende Schaft benötigt Freiraum über dem Ventil.

Kugelhahn vs. Schieber: Vergleich von Kopf zu Kopf

Gehen wir der Sache auf den Grund mit einigen echten Daten:

Geschwindigkeit des Betriebs

- Kugelhahn: 1-2 Sekunden von offen bis geschlossen

- Absperrschieber: 30-60 Sekunden (je nach Größe)

In einem Betrieb, den ich beraten habe, konnte durch die Umstellung auf Kugelhähne die Notabschaltzeit von 45 Sekunden auf 3 Sekunden reduziert werden.

Lebensdauer-Statistiken

Auf der Grundlage von Branchendaten aus dem Jahr 2025:

- Kugelhähne: Durchschnittlich 15-20 Jahre vor größeren Wartungsarbeiten

- Absperrschieber: Durchschnittlich 5-10 Jahre bis zum Austausch der Schaftdichtung

Kostenanalyse

Für ein typisches 2-Zoll-Ventil:

- Absperrschieber: $50-150

- Kugelhahn: $75-200

Aber hier ist die Sache:

Wenn man die Wartungskosten über 10 Jahre berücksichtigt, sind Kugelhähne oft billiger.

Vergleich der Druckverluste

Das hat mich überrascht, als ich es zum ersten Mal erfuhr:

- Absperrschieber (vollständig geöffnet): 0,1-0,2 PSI Abfall

- Kugelhahn (voller Anschluss): 0,1-0,3 PSI Abfall

Für die meisten Anwendungen sind sie im Grunde identisch.

Wann werden Kugelhähne verwendet (mit echten Beispielen)

Nach meiner Erfahrung sind Kugelhähne die beste Wahl:

1. Erdgas-Leitungen

Warum? Diese blasendichte Abdichtung ist für die Sicherheit entscheidend. Außerdem brauchen Sie in Notfällen eine schnelle Abschaltmöglichkeit.

2. Druckluftsysteme

Warum? Häufiges Ein- und Ausschalten würde die Packung eines Schieberventils innerhalb weniger Monate zerstören.

3. Chemische Verarbeitung

Warum? Viele Kugelhähne haben PTFE-Sitze, die aggressiven Chemikalien widerstehen.

4. Hauptabsperrungen für Wohngebäude

Warum? Wenn Ihr Rohr um 2 Uhr morgens platzt, wollen Sie es JETZT abstellen, nicht erst in 60 Sekunden.

5. Feuerschutzsysteme

Warum? Schnelles Handeln kann buchstäblich Leben retten.

Wenn Schieberventile mehr Sinn machen

Absperrschieber sind nicht tot. Hier sind sie am besten:

1. Große Wasserversorgungsleitungen

Warum? Bei Rohren über 12 Zoll sind Absperrschieber wesentlich billiger und für den seltenen Gebrauch gut geeignet.

2. Slurry-Anwendungen

Warum? Die Durchgangskonstruktion bewältigt Partikel besser als Kugelventile.

3. Hochtemperaturdampf

Warum? Metallisch dichtende Schieber halten extremer Hitze besser stand als Kugelhahnsitze.

4. Drosselung von Anwendungen

Warum? Wenn Sie den Durchfluss steuern müssen (nicht nur ein/aus), zerstören sich Schieber nicht selbst.

Häufige Fehler, die viel Geld kosten

Ich habe diese Fehler schon unzählige Male gesehen:

Fehler #1: Verwendung von Kugelhähnen zur Drosselung

Ein Werk versuchte, den Durchfluss in seinem Kühlwassersystem mit Kugelhähnen zu steuern. Innerhalb von 6 Monaten war jedes Ventil undicht.

Die Lösung: Verwenden Sie Absperrschieber oder geeignete Regelventile zur Drosselung.

Fehler #2: Installation von Schieberventilen, bei denen es auf Geschwindigkeit ankommt

In einem lebensmittelverarbeitenden Betrieb wurden Schieber in einem chemischen Notabspritzsystem eingesetzt. Während eines tatsächlichen Notfalls verursachte die 45-sekündige Schließzeit einen Produktverlust von $50.000.

Die Lösung: Verwenden Sie immer Kugelhähne, wenn es auf schnelle Reaktion ankommt.

Fehler #3: Wasserschlag ignorieren

Hochdrucksysteme + Kugelhähne + ungeschultes Personal = Rohrbruch.

Die Lösung: Installieren Sie Wasserschlagschutzvorrichtungen oder schulen Sie das Bedienungspersonal, die Ventile langsam zu schließen.

Mein Schritt-für-Schritt-Ventilauswahlprozess

So helfe ich meinen Kunden bei der Auswahl des richtigen Ventils:

Schritt 1: Definieren Sie Ihre Anwendung

Fragen Sie sich selbst:

- Was fließt durch sie hindurch? (Wasser, Gas, Chemikalien, usw.)

- Wie hoch ist der Druck und die Temperatur?

- Wie oft wird es betrieben?

Schritt 2: Bestimmen Sie Ihre Prioritäten

Ordnen Sie diese in der Reihenfolge von am wichtigsten bis am unwichtigsten:

- Geschwindigkeit des Betriebs

- Zuverlässigkeit der Versiegelung

- Anfängliche Kosten

- Anforderungen an die Wartung

- Platzbeschränkungen

Schritt 3: Lokale Vorschriften prüfen

Einige Gerichtsbarkeiten schreiben bestimmte Ventiltypen vor. In vielen Gebieten sind zum Beispiel Kugelhähne für Gasleitungen vorgeschrieben.

Schritt 4: Künftige Bedürfnisse berücksichtigen

Werden Sie diese Ventile später automatisieren müssen? Kugelhähne sind viel einfacher zu automatisieren.

Schritt 5: Berechnung der Gesamtkosten

Achten Sie nicht nur auf den Kaufpreis. Berücksichtigen Sie:

- Installationskosten

- Erwartete Wartung

- Energieverluste (Druckabfall)

- Mögliche Ausfallzeiten

Erweiterte Überlegungen für 2026

Die Armaturenindustrie steht nicht still. Hier ist, was neu ist:

Intelligente Ventiltechnik

Neu IoT-fähig Ventile können ihren Status melden, den Wartungsbedarf vorhersagen und sogar ferngesteuert arbeiten. Kugelhähne sind aufgrund ihrer einfachen Bedienung führend in diesem Trend.

Werkstoff-Innovationen

Moderne Polymere und Beschichtungen verlängern die Lebensdauer von Ventilen dramatisch. Ich sehe PTFE-beschichtete Kugelhähne, die in aggressiven Anwendungen 25 Jahre und länger halten.

Umweltvorschriften

Strengere Emissionsnormen erhöhen die Nachfrage nach besser dichtenden Ventilen. Kugelhähne haben hier einen klaren Vorteil.

Installationstipps zur Vermeidung von Problemen

Unabhängig davon, ob Sie sich für Kugelhähne oder Schieber entscheiden, ist der richtige Einbau entscheidend:

Für Kugelhähne:

- Unterstützung der Pipeline - Kugelhähne halten der Belastung der Rohre nicht stand

- Durchflussrichtung prüfen - Einige Kugelhähne sind Wegeventile

- Griffspiel lassen - Der 90-Grad-Schwung braucht Platz

- Orientierung berücksichtigen - Ein horizontaler Stamm ist in der Regel am besten

Für Schieberventile:

- Wenn möglich, aufrecht einbauen - Verhindert die Ansammlung von Ablagerungen

- Spindelspiel zulassen - Aufstrebende Stämme brauchen Platz

- Niemals gewaltsam schließen - Zu festes Anziehen beschädigt Sitze

- Regelmäßig schmieren - Verhindert das Binden von Stielen

Wartungspläne, die tatsächlich funktionieren

Das empfehle ich meinen Kunden:

Wartung von Kugelhähnen:

- Monatlich: Schalten Sie das Ventil ein, wenn es normalerweise statisch ist.

- Jährlich: Auf externe Lecks prüfen

- Alle 5 Jahre: Austausch von Sitzen und Dichtungen in Betracht ziehen

Wartung von Absperrschiebern:

- Vierteljährlich: Gewinde der Spindel schmieren

- Halbjährlich: Packung prüfen und einstellen

- Jährlich: Vollständiger Betriebstest

- Alle 3-5 Jahre: Verpackung umpacken oder ersetzen

Die endgültige Entscheidung treffen

Also, Kugelhahn vs. Schieber - wer gewinnt?

Das ist die Quintessenz:

Für die meisten modernen Anwendungen sind Kugelhähne die bessere Wahl. Sie sind zuverlässiger, erfordern weniger Wartung und bieten eine bessere Abdichtung.

Aber Schieber haben nach wie vor ihre Berechtigung, vor allem bei Anwendungen mit großem Durchmesser und seltenem Gebrauch, bei denen die Kosten entscheidend sind.

Mein Rat?

Im Zweifelsfall sollten Sie sich für einen Kugelhahn entscheiden. Die höheren Anschaffungskosten machen sich in der Regel durch geringeren Wartungsaufwand und höhere Zuverlässigkeit bezahlt.

Denken Sie daran: Die Wahl des richtigen Ventils hängt von IHRER spezifischen Situation ab. Nutzen Sie diesen Leitfaden, um Ihren Bedarf zu ermitteln, und Sie werden die richtige Entscheidung treffen.

Jetzt wissen Sie genau, wie Sie sich zwischen einem Kugelhahn vs. Schieber für jede Anwendung. Der Schlüssel liegt darin, den Ventiltyp auf Ihre spezifischen Bedürfnisse abzustimmen, anstatt einfach die billigste Option zu wählen.