Haben Sie schon einmal vor zwei ähnlich aussehenden Ventilen gestanden und sich gefragt, welches das richtige für Ihr Projekt ist?

Ich habe das schon erlebt.

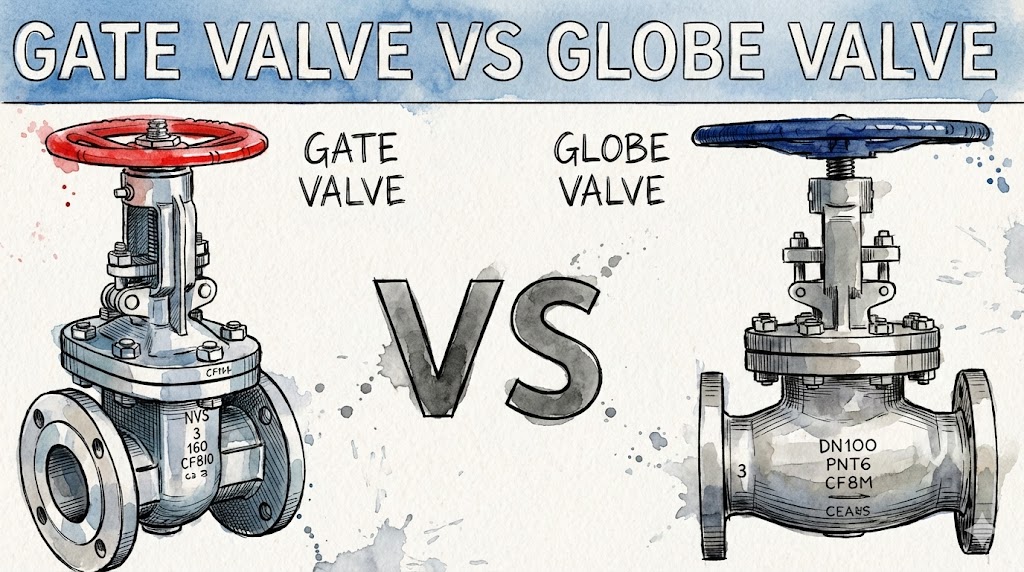

So sieht es aus: Schieber und Ventile sehen zwar äußerlich wie Zwillinge aus, sind aber in puncto Leistung völlig unterschiedlich.

Und wenn Sie sich für die falsche Lösung entscheiden? Das kann Sie Tausende an Reparaturen, Ausfallzeiten und Kopfschmerzen kosten.

In diesem Leitfaden werden Sie als Fachmann Absperrschieber und Hersteller von Absperrventilen, Ich werde genau aufschlüsseln, wann welcher Ventiltyp zu verwenden ist. Außerdem verrate ich Ihnen einige Insider-Tipps, die Sie vor kostspieligen Fehlern bewahren werden.

Klingt gut? Tauchen wir ein.

Kurze Zusammenfassung

- Verwenden Sie Absperrschieber zur Auf/Zu-Absperrung, wenn ein geringer Druckabfall und ein bidirektionaler Durchfluss wichtig sind; verwenden Sie sie nicht zur Drosselung.

- Verwenden Sie Durchgangsventile, wenn eine genaue Durchflussregelung, stabile Teilöffnungen und eine hervorragende Abdichtung erforderlich sind, Sie aber mit einem höheren Druckverlust und höheren Kosten rechnen müssen.

- Folgen Sie dem 5-stufigen Entscheidungsprozess: Definieren Sie den Bedarf, prüfen Sie die Druckverlusttoleranz, bestätigen Sie die Durchflussrichtung, bewerten Sie die Medien und berechnen Sie die Gesamtkosten (Installation, Wartung, Energie, Lebensdauer).

- Vermeiden Sie häufige Fehler: Drosselung mit Schiebern, rückwärtiger Einbau von Durchgangsventilen, Überdimensionierung und Ignorieren von Cv-Werten.

Was ist der große Unterschied zwischen Schieber- und Durchgangsventilen?

Lassen Sie mich mit einer kurzen Geschichte beginnen.

Letztes Jahr rief mich ein Kunde in Panik an. Er hatte überall in seinem Haus Schieber installiert. Drosselung System, und die Ventile fielen links und rechts aus.

Warum? Sie haben das falsche Ventil für die Aufgabe gewählt.

Hier ist, was Sie wissen müssen:

Absperrschieber = Ein/Aus-Trennung (wie ein Lichtschalter)

Durchgangsventile = Durchflusssteuerung und -regelung (wie ein Dimmschalter)

Das ist die einfachste Art, darüber nachzudenken.

Aber unter der Haube steckt noch viel mehr. Lassen Sie mich das für Sie aufschlüsseln.

Schieberventile: Der Straight Shooter

Schieber sind die Arbeitspferde der Armaturenwelt.

Stellen Sie sich diese wie ein Garagentor vor. Die keilförmiges Tor gleitet auf und ab, senkrecht zur Strömung.

Wenn sie offen ist? Sie erhalten einen direkten Durchfluss mit minimalem Widerstand.

Wenn sie geschlossen ist? Vollständige Abschaltung.

Das macht Schieber zu etwas Besonderem:

1. Niedriger Druckverlust

Das ist eine große Sache.

Wenn sie vollständig geöffnet sind, bieten Schieber fast keinen Durchflusswiderstand. Tatsächlich zeigen Studien, dass Schieber bis zu 85% weniger Druckabfall im Vergleich zu Durchgangsventilen.

(Das bedeutet mehr Effizienz und niedrigere Energiekosten.)

2. Bi-direktionaler Fluss

Absperrschiebern ist es egal, in welche Richtung die Flüssigkeit fließt. Sie funktionieren in beide Richtungen gleich gut.

Dank dieser Flexibilität eignen sie sich perfekt für Anwendungen, bei denen sich der Durchfluss umkehren kann.

3. Einfaches Design

Weniger Komplexität = weniger, was schief gehen kann.

Die unkomplizierte Konstruktion macht Schieber zu Schieberventilen:

- Billiger in der Herstellung

- Leichtere Wartung

- Zuverlässiger für einfache Ein/Aus-Dienste

Aber hier ist der Haken an der Sache...

Absperrschieber sind zum Drosseln ungeeignet.

Versuchen Sie, sie teilweise geöffnet zu verwenden? Sie werden es schaffen:

- Übermäßige Vibration

- Schnelle Abnutzung der Dichtungsflächen

- Mögliche Schäden am Tor

Ich habe schon gesehen, wie Tore buchstäblich abbrachen und in die Rohrleitung fielen. Das macht keinen Spaß.

Durchgangsventile: Der Kontrollfreak (auf eine gute Art)

Lassen Sie uns nun über Ventile sprechen.

Dies sind Ihre Präzisionsinstrumente. Die Scheibenbewegung ist parallel zum Durchfluss, was Ihnen eine unglaubliche Kontrolle über die Durchflussmenge ermöglicht.

Stellen Sie sich einen Stößel vor, der sich gegen einen Sitz auf und ab bewegt. So funktioniert im Wesentlichen ein Durchgangsventil.

Warum Geradsitzventile für die Steuerung rocken:

1. Hervorragende Drosselungsfähigkeit

Im Gegensatz zu Schiebern sind Absperrventile gerne teilweise geöffnet.

Das Design erlaubt es:

- Präzise Durchflussregelung

- Stabiler Betrieb in jeder Position

- Minimale Vibration

2. Hervorragende Abdichtung

Durchgangsventile halten in der Regel 2-3 Mal länger als Schieber, was die Dichtungsintegrität betrifft.

Warum? Der Schließvorgang erzeugt eine festere Dichtung mit weniger Verschleiß an den Sitzflächen.

3. Schnelle Bedienung

Da sich der Ventilteller nur über eine kurze Strecke bewegen muss, öffnen und schließen sich Ventile schneller als Schieber.

(Hervorragend geeignet für Anwendungen, die einen häufigen Betrieb erfordern).

Die Abwägungen:

Nichts ist perfekt, oder?

Durchgangsventile haben einige Nachteile:

- Hoher Druckabfall (auch bei voller Öffnung)

- Teurer als Absperrschieber

- Unidirektionaler Fluss (beachten Sie den Pfeil!)

Schieber und Durchgangsventil: Vergleich von Kopf zu Kopf

Ich möchte Ihnen einige reale Daten aus der Praxis mitteilen:

| Merkmal | Absperrschieber | Durchgangsventil |

|---|---|---|

| Druckabfall | 0,1-0,2 psi | 5-10 psi |

| Kosten | $100-500 | $150-750 |

| Typische Lebenserwartung | 15-20 Jahre | 20-30 Jahre |

| Beste Verwendung | Isolierung | Ablaufsteuerung |

(Dies sind Durchschnittswerte für 4-Zoll-Ventile im Wasserbetrieb bei 100 psi).

Wann werden Schieber verwendet?

Hier kommen die Schieber zum Einsatz:

1. Hauptwasserleitungen

In kommunalen Wasserversorgungssystemen werden Schieber in großem Umfang eingesetzt. Warum eigentlich? Sie benötigen einen vollen Durchfluss bei minimalem Druckverlust.

2. Öl- und Gaspipelines

Wenn man Rohöl über Hunderte von Kilometern transportiert, zählt jeder PSI. Schieberventile halten diese Druckabfälle auf ein Minimum.

3. Schüttgutumschlag

Schlämme, Körner und andere Schüttgüter? Schieber (vor allem Plattenschieber) schneiden direkt durch.

4. Feuerschutzsysteme

Ein schneller, vollständiger Durchfluss ist entscheidend. Absperrschieber liefern.

Profi-Tipp: Installieren Sie Schieber immer so, dass sie 95% entweder vollständig geöffnet oder vollständig geschlossen sind.

Wenn Durchgangsventile Ihre beste Wahl sind

Durchgangsventile zeichnen sich durch folgende Eigenschaften aus industrielle Anwendungen:

1. Dampfsysteme

Bei Dampfanwendungen ist die Temperaturregelung entscheidend. Durchgangsventile bieten die erforderliche präzise Drosselung.

2. Kühlwassersysteme

Die Aufrechterhaltung optimaler Temperaturen? Das erfordert eine ständige Anpassung des Durchflusses. Durchgangsventile sind dafür perfekt geeignet.

3. Chemische Zufuhrsysteme

Bei der Dosierung von Chemikalien kommt es auf Genauigkeit an. Durchgangsventile bieten Ihnen diese Präzision.

4. Heizöl-Systeme

Die Regulierung des Brennstoffflusses zu den Brennern erfordert eine Feinsteuerung, die nur Hubventile bieten.

Die versteckten Kosten, über die niemand spricht

Es gibt etwas, das Ihnen die Ventilhersteller nicht sagen werden:

Der Anschaffungspreis ist nur die Spitze des Eisbergs.

Berücksichtigen Sie diese Faktoren:

Installationskosten:

- Durchgangsventile benötigen aufgrund ihres Gewichts oft eine Abstützung

- Absperrschieber benötigen mehr vertikalen Spielraum

Kosten für die Instandhaltung:

- Ventilsitze verschleißen schneller, wenn sie zum Drosseln verwendet werden

- Durchgangsventilpackungen müssen in der Regel häufiger nachgestellt werden

Energiekosten:

- Der Druckabfall in Durchgangsventilen? Er kostet Sie Pumpleistung

- Über einen Zeitraum von 10 Jahren kann dies den Kaufpreis des Ventils übersteigen.

Wie man wählt: Mein 5-stufiger Entscheidungsprozess

Nach 20 Jahren Erfahrung in diesem Bereich habe ich eine narrensichere Methode entwickelt:

Schritt 1: Definieren Sie Ihren Hauptbedarf

Fragen Sie sich selbst: “Muss ich den Fluss kontrollieren oder nur stoppen?”

Steuerung = Durchgangsventil

Stop/Start = Schieberventil

Schritt 2: Prüfen Sie Ihre Druckanforderungen

Kann Ihr System einen Abfall von 5-10 psi verkraften?

Ja = Beide Ventile funktionieren

Nein = nur Absperrschieber

Schritt 3: Flussrichtung berücksichtigen

Sie benötigen einen bidirektionalen Durchfluss? Der Schieber ist Ihre einzige Option.

Schritt 4: Bewerten Sie Ihre Medien

Schlämme oder Feststoffe? Absperrschieber sind besser geeignet.

Saubere Flüssigkeiten? Beides geht.

Schritt 5: Berechnung der Gesamtkosten

Achten Sie nicht nur auf den Kaufpreis. Berücksichtigen Sie:

- Installation

- Wartung

- Energiekosten

- Erwartete Lebenserwartung

Häufige Fehler, die es zu vermeiden gilt (vom Schmerz anderer lernen)

Ich habe diese Fehler schon unzählige Male gesehen:

Irrtum #1: Absperrschieber zur Drosselung verwenden

Dadurch wird das Ventil in Monaten statt in Jahren zerstört. Ein Kunde ersetzte 50 Absperrschieber nach nur 6 Monaten Drosselungsbetrieb.

Fehler #2: Einbau von Durchgangsventilen in umgekehrter Reihenfolge

Der Strömungspfeil ist kein Ratschlag. Rückwärts einbauen kann dazu führen:

- Übermäßiger Druckabfall

- Vorzeitiger Verschleiß

- Vollständige Unterbrechung des Durchflusses

Fehler #3: Überdimensionierung von Ventilen

Größer ist nicht immer besser. Überdimensionierte Ventile:

- Mehr kosten

- Schlecht operieren

- Schneller verschleißen

Fehler #4: Cv-Werte ignorieren

Der Durchflusskoeffizient (Cv) bestimmt die tatsächliche Durchflusskapazität. Vergewissern Sie sich immer, dass Ihr Ventil die erforderlichen Durchflussraten bewältigen kann.

Erweiterte Überlegungen für 2026

Die Armaturenindustrie steht nicht still. Hier ist, was neu ist:

Intelligente Ventiltechnik

Neu Linearbewegungsventil Entwürfe umfassen:

- IoT Sensoren für die Echtzeitüberwachung

- Algorithmen zur vorausschauenden Wartung

- Automatische Positionsrückmeldung

Werkstoff-Innovationen

Moderne Legierungen und Beschichtungen verlängern die Lebensdauer von Ventilen:

- Keramisch ausgekleidete Schieber für abrasiven Einsatz

- Ventilsitze mit Stellitbeschichtung

- Korrosionsbeständige Overlays

Normen für die Energieeffizienz

Neue Vorschriften, die 2026 in Kraft treten sollen, fordern niedrigere Druckverluste. Dies könnte bei einigen Anwendungen den Ausschlag zugunsten von Schiebern geben.

Meine persönlichen Empfehlungen

Auf der Grundlage von Tausenden von Ventilinstallationen schlage ich Folgendes vor:

Für den Hausgebrauch:

- Hauptabsperrungen: Absperrschieber

- Ventile unter der Spüle: Durchgangsventile (leichter zu regulieren)

Für den industriellen Einsatz:

- Prozesssteuerung: Durchgangsventile mit Antrieben

- Absperrventile: Absperrschieber (manuell oder automatisch)

Für besondere Anwendungen:

- Hohe Temperaturen (>500°F): Durchgangsventile mit verlängerten Ventildeckeln

- Kryogener Betrieb: Spezialschieber mit verlängerten Spindeln

Das Fazit zur Auswahl von Schieber- und Durchgangsventilen

Es läuft auf Folgendes hinaus:

Absperrschieber sind Ihre erste Wahl für Isolationsventil Anwendungen, bei denen ein voller Durchfluss und minimaler Druckabfall erforderlich sind.

Durchgangsventile eignen sich trotz ihres höheren Druckabfalls hervorragend zur Durchflussregelung und Drosselung.

Keiner von beiden ist von Natur aus “besser” - sie sind nur für unterschiedliche Aufgaben konzipiert.

Wählen Sie das richtige Werkzeug für die jeweilige Aufgabe, und Ihre Ventile werden Ihnen jahrzehntelang gute Dienste leisten.

Falsch gewählt? Sie werden der Geschäftsleitung Budgetüberschreitungen und Ausfallzeiten erklären müssen.

Sie haben die Wahl.

Denken Sie daran: Wenden Sie sich im Zweifelsfall an einen Ventilspezialisten. Die Kosten für eine fachkundige Beratung sind nichts im Vergleich zu den Kosten eines Ventilausfalls.

Jetzt wissen Sie genau, wann Sie Absperrschieber und wann Sie Durchgangsventile verwenden sollten. Kein Rätselraten mehr. Keine kostspieligen Fehler mehr.

Zeit, die richtige Wahl für Ihre Anwendung zu treffen.