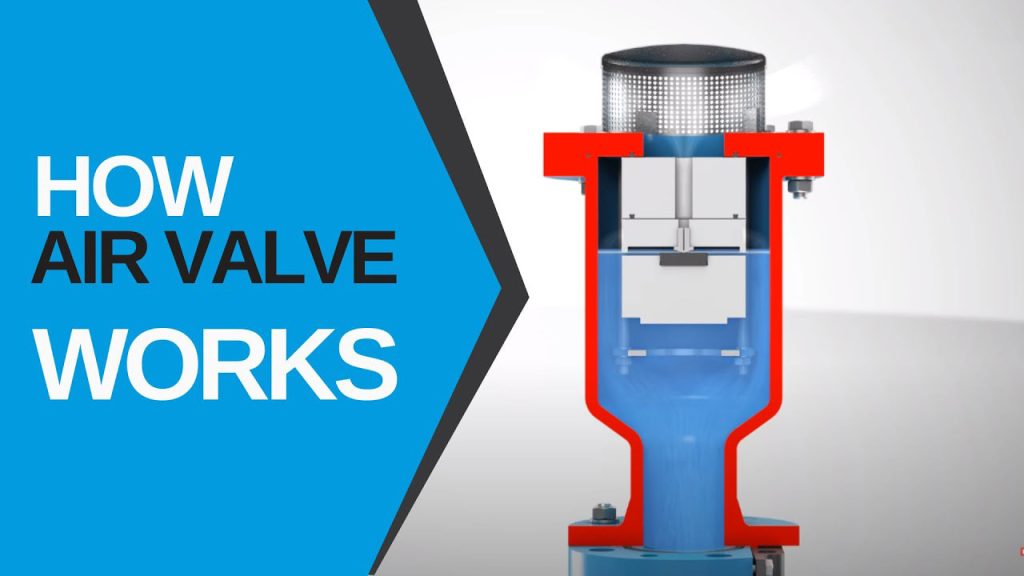

So sieht es aus:

Entlüftungsventile mögen wie einfache Geräte erscheinen, aber in Wirklichkeit sind sie die unbesungenen Helden der Wasserverteilungssysteme. Wie kann ein Luftventil arbeiten? Einfach ausgedrückt, steuern diese mechanischen Vorrichtungen automatisch die Luftbewegung in und aus den Rohrleitungen mit Hilfe eines Schwimmmechanismus, der nach dem Auftriebsprinzip funktioniert. Sie lassen eingeschlossene Luft während des normalen Betriebs ab, lassen Luft ein, um die Bildung eines Vakuums zu verhindern, und lassen Luft während der Befüllung der Pipeline ab.

Aber es geht um viel mehr als das.

Ohne ordnungsgemäß funktionierende Entlüftungsventile kann Ihr Rohrleitungssystem ernsthafte Probleme wie Wasserschlag, verringerte Durchflussleistung und sogar einen katastrophalen Rohrbruch erleiden.

Heute als Profi LuftventilherstellerIn diesem Kapitel erläutere ich genau, wie Luftventile funktionieren, warum sie wichtig sind und wie man das Beste aus ihnen herausholen kann.

Inhaltsübersicht

- Was genau ist ein Luftventil?

- Die Wissenschaft hinter der Funktionsweise der Schwimmermechanik

- Arten von Luftventilen (und wann sie zu verwenden sind)

- Warum Luftventile für die Effizienz von Pipelines so wichtig sind

- Strategische Platzierung: Wo Luftventile zu installieren sind

- Bewährte Installationspraktiken, die tatsächlich von Bedeutung sind

- Häufige Probleme (und wie man sie behebt)

- Fortgeschrittene Anwendungen, über die Sie Bescheid wissen sollten

- ROI und Kostenüberlegungen

- Das Wichtigste zum Betrieb von Luftventilen

Was genau ist ein Luftventil?

Ein Luftventil ist ein hydromechanisches Durchflussregelgerät, das für die automatische Steuerung der Luft in Flüssigkeitsrohrsystemen entwickelt wurde.

Betrachten Sie es als das Atmungssystem Ihrer Pipeline.

Diese Ventile erfüllen drei wichtige Funktionen:

- Luft ablassen während des Betriebs - Kontinuierliches Entlüften von kleinen Lufteinschlüssen, die sich ansammeln

- Luft beim Entleeren einlassen - Verhinderung gefährlicher Vakuumbedingungen

- Luft beim Befüllen ablassen - Schnelles Entlüften großer Luftmengen beim Füllen von Leerrohren

Das Schöne an Luftventilen? Sie funktionieren automatisch, ohne externe Energie oder manuelles Eingreifen.

Die Wissenschaft hinter der Funktionsweise der Schwimmermechanik

Kommen wir nun zu den Mechanismen.

Die meisten Luftventile verwenden ein Schwimmmechanismus die nach einem einfachen Prinzip funktioniert: Auftrieb.

Und so funktioniert das Ganze:

Wenn die Pipeline voll ist (Normalbetrieb)

Wenn Ihre Rohrleitung normal läuft, füllt sich das Ventilgehäuse mit Flüssigkeit. Der Schwimmer im Inneren des Ventils steigt mit dem Flüssigkeitsstand an, ähnlich wie ein Schwimmkörper beim Angeln. Diese Aufwärtsbewegung drückt den Schwimmer gegen eine kleine Öffnung, wodurch eine Dichtung entsteht, die das Ventil geschlossen hält.

Es tritt keine Flüssigkeit aus. Keine Probleme.

Wenn sich Luft ansammelt

Aber jetzt wird es interessant.

Wenn sich kleine Lufttaschen im Ventil ansammeln, verdrängen sie die Flüssigkeit. Der Flüssigkeitsstand sinkt, und damit auch der Schwimmer. Wenn der Schwimmer weit genug abgesunken ist, zieht er sich von der Öffnung weg und öffnet das Ventil.

Die eingeschlossene Luft entweicht in die Atmosphäre, bis wieder Flüssigkeit in das Ventil eintritt, den Schwimmer anhebt und es wieder verschließt.

Dieser Zyklus wiederholt sich automatisch, wenn sich Luft ansammelt.

Unter Vakuumbedingungen

Wenn eine Rohrleitung ausläuft oder ein plötzlicher Druckabfall auftritt, wird es kritisch.

Die Flüssigkeit strömt aus dem Ventilgehäuse, wodurch der Schwimmer vollständig absinkt. Dadurch wird eine große Öffnung geöffnet, durch die große Mengen Luft einströmen. Diese Vakuumvermeidung ist von entscheidender Bedeutung - ohne sie könnten Ihre Rohre buchstäblich durch Unterdruck zusammenbrechen.

Arten von Luftventilen (und wann sie zu verwenden sind)

Nicht alle Luftventile sind gleich.

Die Wahl des falschen Ventiltyps kann sogar genauso schlimm sein wie ein fehlendes Ventil.

Hier sind die drei Haupttypen:

1. Entlüftungsventile

Geeignet für: Ablassen kleiner, kontinuierlicher Luftansammlungen unter Druck

Wie sie funktionieren: Konstruktion mit kleiner Öffnung und gewichtetem Schwimmsystem

Wesentliche Merkmale:

- Lässt bei normalem Betrieb Luftblasen frei

- Arbeitet unter vollem Systemdruck

- Begrenzte Kapazität für große Luftmengen

2. Luft/Vakuum-Ventile

Geeignet für: Schutz gegen Unterdruck und Befüllungs-/Entleerungsvorgänge

Wie sie funktionieren: Große Öffnung, die normalerweise offen ist und sich schließt, wenn Wasser eintritt

Wesentliche Merkmale:

- Nimmt schnell große Luftmengen auf

- Verhindert den Zusammenbruch von Pipelines

- Kann die Luft unter Druck nicht ablassen

3. Kombinierte Luftventile

Geeignet für: Vollständiges Luftmanagement (mein persönlicher Favorit)

Wie sie funktionieren: Enthält sowohl kleine als auch große Öffnungen in einer Einheit

Wesentliche Merkmale:

- Behandelt alle Luftventil Funktionen

- Vielseitigste Option

- Höhere Kosten, aber besserer Schutz

Warum Luftventile für die Effizienz von Pipelines so wichtig sind

Ich möchte mich klar ausdrücken:

Luft in den Rohrleitungen zu ignorieren ist wie Cholesterin in den Arterien zu ignorieren. Irgendwann wird etwas nachgeben.

Das passiert, wenn die Luftventile nicht richtig funktionieren:

Reduzierte Pumpleistung

Lufteinschlüsse führen zu Blockaden, die die Pumpen zwingen, härter zu arbeiten. Ich habe Systeme gesehen, bei denen Lufteinschlüsse den Energieverbrauch um 15-20% erhöhten.

Das ist echtes Geld, das den Bach runtergeht.

Wasserschlag und Überschwemmungsschäden

Wenn sich Lufteinschlüsse lösen und flussabwärts wandern, können sie verheerende Druckstöße verursachen. Wir sprechen hier von Kräften, die Rohre buchstäblich auseinanderreißen können.

Fehler bei der Messung

Luftblasen bringen Durchflussmesser und Messgeräte durcheinander. Man kann nicht verwalten, was man nicht genau messen kann.

Korrosionsbeschleunigung

Sauerstoff in eingeschlossener Luft beschleunigt die Rohrleitung Korrosionvor allem an hohen Temperaturpunkten. Dies verkürzt die Lebensdauer der Rohrleitungen drastisch.

Strategische Platzierung: Wo Luftventile zu installieren sind

Bei Luftventilen ist der Standort alles.

Wenn man sie an der falschen Stelle anbringt, sind sie im Grunde nur teure Dekoration.

Hier brauchen Sie Luftventile:

Höhepunkte in der Pipeline

Luft steigt natürlich auf und sammelt sich in Spitzenzeiten. Dies ist die Priorität #1 für Entlüftungsventil Platzierung.

Lange horizontale Läufe

Selbst "flache" Rohre haben kleine Höhenunterschiede, in denen sich Luft ansammelt. Installieren Sie auf langen Strecken alle 1.500-2.500 Fuß Ventile.

Änderungen des Rohrgefälles

Überall dort, wo die Rohrleitung von einem aufsteigenden in einen absteigenden Zustand übergeht, muss sie geschützt werden.

Nach Pumpen und Booster

Pumpen können durch Kavitation oder Dichtungslecks Luft einführen. Bauen Sie immer Kombiventile nachgeschaltet ein.

Vor und nach den Ventilen

Absperrventile, Regelventile und PRVs erzeugen Turbulenzen, die gelöste Luft freisetzen.

Bewährte Installationspraktiken, die tatsächlich von Bedeutung sind

Die Sache ist die:

Auch die besten Luftventil wird nicht funktionieren, wenn es falsch installiert ist.

Befolgen Sie diese Leitlinien:

Immer vertikal installieren

Luftventile müssen senkrecht und mit dem Einlass nach unten montiert werden. In jeder anderen Ausrichtung funktionieren sie einfach nicht.

Absperrventile hinzufügen

Installieren Sie ein Absperrventil unter jedem Luftventil. Sie werden mir dankbar sein, wenn die Wartung ansteht.

Richtige Belüftung sicherstellen

Luftventile müssen atmen können. Installieren Sie sie dort, wo die ausgestoßene Luft entweichen und frische Luft ungehindert einströmen kann.

Korrekte Größe

Unterdimensionierte Ventile können mit der Luftansammlung nicht Schritt halten. Überdimensionierte Ventile verschwenden Geld. Verwenden Sie die Dimensionierungstabellen der Hersteller, die auf dem Rohrdurchmesser und der Durchflussmenge basieren.

Häufige Probleme (und wie man sie behebt)

Auch bei ordnungsgemäßer Installation können Probleme auftreten.

Hier sind die häufigsten Probleme, die ich sehe:

Ventil lässt keine Luft ab

Die Ursache: In der Regel verstopft ein Fremdkörper die Öffnung

Reparieren: Demontieren und gründlich reinigen

Kontinuierliche Wasserabgabe

Die Ursache: Beschädigte Schwimmer oder verschlissene Dichtungen

Reparieren: Interne Komponenten austauschen

Ventilklappern

Die Ursache: Überdimensioniertes Ventil oder turbulente Strömung

Reparieren: Einbau einer Drosselvorrichtung oder Anpassung der Ventilgröße

Vorzeitiges Scheitern

Die Ursache: Falsches Ventilmaterial für die Anwendung

Reparieren: Aufrüstung auf geeignete Materialien (Edelstahl für korrosive Umgebungen)

Fortgeschrittene Anwendungen, über die Sie Bescheid wissen sollten

Luftventile sind nicht nur für Wasserleitungen geeignet.

Hier sind einige spezielle Anwendungen:

Abwassersysteme

Bei der Abwasserentsorgung entstehen durch Zersetzung Gase. Spezielle Abwasserluftventile bewältigen diese korrosiven Gase und verhindern gleichzeitig Verschmutzungen.

Chemische Verarbeitung

Ventile aus Edelstahl mit speziellen Dichtungen halten aggressive Chemikalien sicher aus.

Hochdruck-Systeme

Verstärkte Ventile sind für Drücke bis zu 300 PSI für industrielle Anwendungen geeignet.

ROI und Kostenüberlegungen

Lassen Sie uns über Geld reden.

Qualitätsluftventile sind nicht billig. Aber das ist es auch nicht:

- Auswechseln geplatzter Rohre

- Erhöhte Energiekosten

- Systemausfallzeit

- Vorzeitiger Ausfall der Pumpe

Ich habe richtige Luftventil Die Installation amortisiert sich innerhalb von 12-18 Monaten allein durch Energieeinsparungen.

Das Wichtigste zum Betrieb von Luftventilen

Wie kann ein Luftventil arbeiten? Durch die ausgeklügelte Nutzung von Auftriebsprinzipien und AutomatikbetriebDiese Geräte schützen Pipelines vor luftbedingten Problemen, ohne dass Strom oder manuelle Eingriffe erforderlich sind. Die Schwimmmechanismus hebt und senkt sich mit dem Flüssigkeitsstand und öffnet und schließt die Öffnungen, um eingeschlossene Luft freizusetzen, Luft während des Vakuums einzulassen und die optimale Pipeline-Effizienz. Ob Verwaltung Lufttaschen unter Höhepunkte in der Pipeline Systeme oder zur Verhinderung eines katastrophalen Zusammenbruchs des Vakuums sind Luftventile wesentliche Komponenten, die unsere Wassersysteme reibungslos und sicher fließen.