Ever walked through an industrial facility and wondered how they control all that fluid flowing through those massive pipes?

Here’s the deal: What is a globe valve is one of the most common questions I get from people new to industrial systems. And for good reason.

Globe valves are everywhere. From your local water treatment plant to massive oil refineries, these workhorses are quietly doing their job 24/7.

But here’s the thing…

Most people think all valves are created equal. They’re not.

Globe valves have some unique characteristics that make them perfect for certain applications (and terrible for others).

In this guide, I’m going to break down everything you need to know about globe valves. By the end, you’ll understand exactly when to use them, how they work, and why they’re so popular in industrial applications.

Sound good? Let’s dive in.

Table of contents

- What is a Globe Valve

- How Globe Valves Actually Work

- Types of Globe Valves (And When to Use Each)

- Key Components That Make It Work

- Where You’ll Find Globe Valves in Action

- The Good, The Bad, and The Trade-offs

- Installation and Maintenance Best Practices

- Globe Valve vs. The Competition

- Sizing and Selection Criteria

- Future Trends in Globe Valve Technology

- Conclusion

What is a Globe Valve

A globe valve is a type of industrial valve used to control the flow of fluids (liquids or gases) in a pipeline. Its name comes from its round shape, but many modern globe valves don’t look perfectly round on the outside.

How Globe Valves Actually Work

Let me explain this in simple terms.

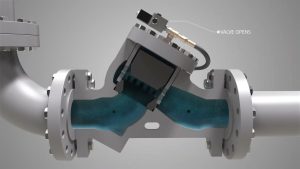

A globe valve operates using linear motion. That means the disc (the part that controls flow) moves straight up and down – not sideways like some other valve types.

Here’s what happens inside:

When Opening:

- You turn the handwheel (or actuator kicks in)

- The stem lifts the disc away from the seat

- Fluid starts flowing through the valve

When Closing:

- The disc moves down toward the seat

- Flow area gets smaller and smaller

- Complete closure stops all flow

But here’s where it gets interesting…

Unlike gate valves that lift completely out of the flow path, globe valve discs stay right in the middle of the action. This creates what we call a “tortuous flow path” – basically, the fluid has to change direction multiple times.

Why does this matter?

This winding path is exactly what gives globe valves their superpower: incredible throttling control.

You can crack open a globe valve just a tiny bit and get precise flow control. Try that with a gate valve and you’ll get unpredictable results (plus you’ll probably damage the valve).

The Internal Flow Pattern

Picture this: fluid enters the valve, hits the internal baffle, gets forced up and around the disc, then changes direction again to exit.

It’s like a NASCAR race with multiple sharp turns instead of a straight highway.

This tortuous path has two major effects:

- Excellent flow control (the good news)

- Higher pressure drop (the trade-off you need to consider)

Types of Globe Valves (And When to Use Each)

Not all globe valves are created equal. Here are the main types you’ll encounter:

Z-Type Globe Valves

This is the most common type you’ll see.

The seat is horizontal, and the stem moves perpendicular to the pipeline. Creates that classic Z-shaped flow path I mentioned earlier.

Best for:

- General throttling applications

- Systems where pressure drop isn’t critical

- Budget-conscious projects (they’re typically the cheapest option)

Y-Type Globe Valves

Here’s where things get interesting.

Y-type valves position the seat and stem at about 45 degrees to the pipe axis. This creates a more streamlined flow path.

The result?

- 10-15% lower pressure drop compared to Z-type

- Better for high-pressure applications

- Can handle higher flow velocities

Pro Tip: If you’re dealing with high-pressure steam or other demanding applications, Y-type is usually worth the extra cost.

Angle Globe Valves

These change the flow direction by 90 degrees.

Instead of needing a separate elbow fitting, the valve does double duty – controlling flow AND changing direction.

Perfect for:

- Tight spaces where you need to change pipe direction anyway

- Reducing the number of joints (fewer potential leak points)

- Systems with fluctuating flow conditions

Bellows-Sealed Globe Valves

The premium option for demanding applications.

These incorporate a bellows system to prevent any leakage along the stem. Zero tolerance for fugitive emissions.

Essential for:

- Hazardous chemicals

- High-purity pharmaceutical processes

- Nuclear applications

- Anywhere environmental compliance is critical

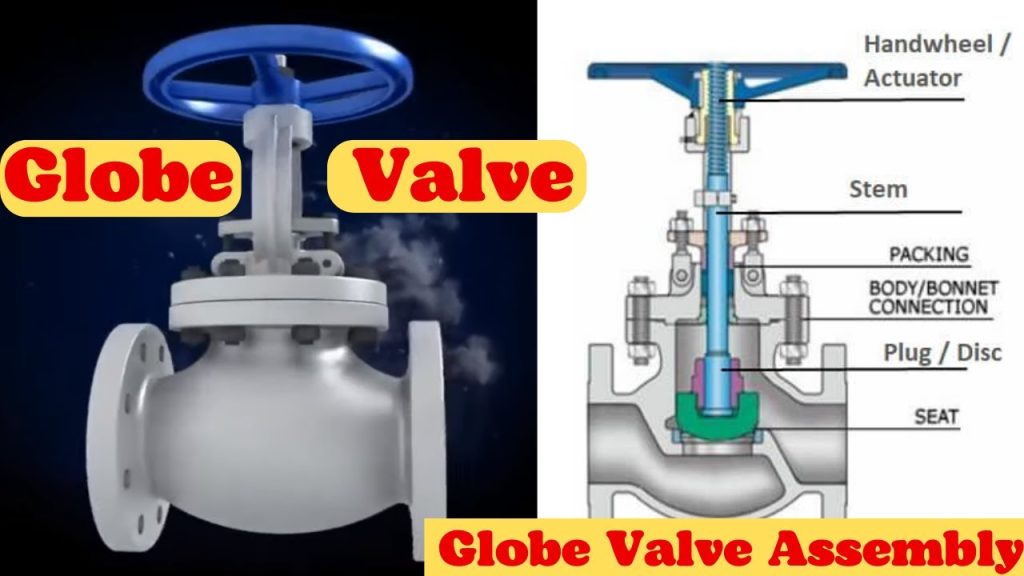

Key Components That Make It Work

Let me break down the anatomy of a globe valve:

Valve Body

The main pressure vessel that houses everything. Usually made from:

- Carbon steel (most common, good for general service)

- Stainless steel (corrosion resistance)

- Cast iron (lower pressure, water applications)

- Specialized alloys (extreme conditions)

Disc and Seat Assembly

This is where the magic happens.

The disc is the movable part that controls flow. The seat is the stationary ring that the disc seals against.

Common disc types:

- Ball discs: General purpose, good sealing

- Needle discs: Ultra-precise control for small lines

- Composition discs: Soft materials for tight shut-off

Stem and Bonnet

The stem connects your handwheel to the disc. The bonnet is like the lid that keeps everything contained while allowing the stem to move.

Critical point: The packing around the stem is what prevents leakage. This is usually the first thing to wear out, so keep an eye on it.

Where You’ll Find Globe Valves in Action

Globe valves show up everywhere precise flow regulation is needed. Here are the most common applications:

Oil and Gas Industry

- Pipeline flow control

- Refinery processing units

- Wellhead operations

- Natural gas distribution

The ability to throttle flow makes them perfect for maintaining steady flow rates despite pressure fluctuations.

Power Generation

- Cooling water systems

- Steam line control

- Feedwater regulation

- Boiler vents and drains

In power plants, you need rock-solid reliability. Globe valves deliver.

Water Treatment

Municipal water plants use globe valves for:

- Flow rate control

- Chemical feed systems

- Backwash operations

- Pressure regulation

HVAC Systems

Building automation systems rely on globe valves for:

- Chilled water control

- Heating fluid regulation

- Temperature zone control

Bottom line? Anywhere you need to adjust flow rates frequently, globe valves are usually your best bet.

The Good, The Bad, and The Trade-offs

Let’s be honest about the pros and cons:

Advantages

Excellent Throttling Control

This is the big one. Globe valves can be positioned anywhere from fully closed to fully open with predictable flow characteristics.

Reliable Shut-off

When properly maintained, they provide tight sealing with minimal leakage.

Durable Design

The robust construction handles frequent operation without excessive wear.

Maintenance-Friendly

Many designs allow you to replace the seat and disc without removing the entire valve from the pipeline.

Disadvantages

Higher Pressure Drop

That tortuous flow path comes with a price – typically 2-4 times the pressure drop of a gate valve.

Higher Cost

More complex internal design means higher manufacturing costs.

Not Great for Slurries

The internal geometry can trap particles, leading to erosion or sticking.

Slower Operation

Linear motion means more turns to go from closed to open compared to quarter-turn valves.

Installation and Maintenance Best Practices

Here’s what I’ve learned from years of working with these valves:

Installation Tips

Check Flow Direction

Most globe valves are unidirectional. Look for the arrow on the valve body and install accordingly.

Provide Adequate Support

Globe valves are heavier than gate valves. Make sure your piping support can handle the weight.

Leave Access Space

You’ll need room above the valve for maintenance. Don’t install it right under a ceiling or other obstruction.

Maintenance Schedule

Monthly Checks:

- Visual inspection for leaks

- Verify smooth operation

- Check packing condition

Annual Maintenance:

- Lubricate stem threads

- Inspect seat and disc condition

- Replace packing if needed

- Test shut-off performance

Pro Tip: Keep spare packing material on hand. It’s the most common maintenance item and relatively cheap insurance.

Globe Valve vs. The Competition

Here’s how globe valves stack up against other common valve types:

Globe vs. Gate Valves

- Gate valves: Better for on/off service, lower pressure drop

- Globe valves: Superior throttling, more frequent operation capability

Globe vs. Ball Valves

- Ball valves: Faster operation, lower pressure drop

- Globe valves: Much better flow control precision

Globe vs. Butterfly Valves

- Butterfly valves: Lighter, cheaper for large sizes

- Globe valves: Better sealing, more precise control

The bottom line? Choose based on your primary need: on/off control (gate/ball) or flow regulation (globe).

Sizing and Selection Criteria

Getting the right size globe valve is crucial. Here’s what to consider:

Flow Coefficient (Cv)

This tells you how much water (in GPM) will flow through the valve at a 1 PSI pressure drop.

Rule of thumb: Size for about 70-80% of maximum Cv to allow for future capacity.

Pressure and Temperature Ratings

Standard pressure classes include:

- 150 PSI (low pressure)

- 300 PSI (medium pressure)

- 600+ PSI (high pressure applications)

Material Selection

Consider:

- Process fluid compatibility

- Temperature extremes

- Corrosion potential

- Regulatory requirements

Future Trends in Globe Valve Technology

The valve industry is evolving. Here’s what I’m seeing in 2025:

Smart Valve Technology

More globe valves now come with:

- Built-in position feedback

- Wireless monitoring capabilities

- Predictive maintenance sensors

Advanced Materials

New alloys and coatings are extending service life in harsh conditions.

Improved Sealing

Better elastomer compounds and metal-to-metal sealing technologies are reducing fugitive emissions.

Conclusion

So what is a globe valve?

It’s your go-to solution when you need precise flow control in industrial applications. Sure, they create higher pressure drops than some alternatives, but that tortuous flow path is exactly what gives them their incredible throttling capability.

Here’s my recommendation:

Use globe valves when:

- You need frequent flow adjustments

- Precise control is more important than minimal pressure drop

- Reliable shut-off is critical

- You’re dealing with steam, hot water, or other fluids that benefit from gradual flow changes

Skip them when:

- You just need simple on/off control

- Pressure drop is a major concern

- You’re handling slurries or dirty fluids

- Quick operation is essential

The key is matching the valve type to your specific application needs. Get that right, and globe valves will serve you reliably for decades.