For many applications requiring bubble-tight shut-off, double offset butterfly valves simply do not make the grade. In these cases, Triple Offset Butterfly Valves are a perfect choice, as BM Engineering Supplies explains in this latest tutorial article.

What is a Triple Offset Butterfly Valve?

The butterfly valve has a very compact design belonging to the quarter family. It’s lightweight, easy to operate, and has lower torque. It’s considered a top choice for critical and severe applications. The triple offset valve design achieves zero leakage on metal-to-metal contact. The hard facing seat eliminates the rubbing between the seat and seal ring through the flow path to extend the cycle life. Its uniform sealing can operate more frequently, and open and close quickly.

What Exactly is Triple Offset Technology

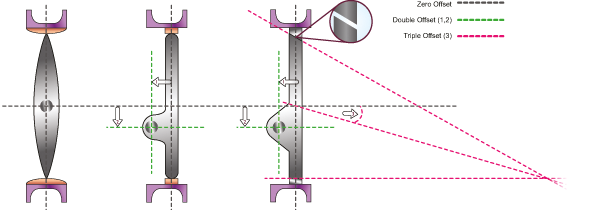

A Triple Offset Butterfly Valve has 3 separate offsets. Two of the offsets apply to the location of the shaft with respect to the centerline of the bore and the centerline of the disc/seat sealing surfaces. The third offset is the design in the axis of the seat cone angle.

Zero Offset: The disc rotates around the centre axis allowing for a potential 360º rotation. Sealing is achieved by the Disc deforming the soft seal resulting in full friction through the full operating cycle.

Double Offset: To allow displacement of the seat the shaft is offset from the centre line of the disc seat and body seal (offset one), and the centre line of the bore (offset two). This creates a cam action during operation to lift the seat out of the seal resulting in friction during the first 10 degrees of opening and the final 10 degrees of closing.

Triple Offset: The third offset is the geometry design of the sealing components. The sealing components are each machined into an offset conical profile resulting in a right-angled cone. This ensures friction-free stroking throughout its operating cycle. Contact is only made at the final point of closure with the 90° angle acting as a mechanical stop; resulting in no over-travel of the disc seat.

Benefits of Triple Offset Butterfly Valves

Triple offset, as the name implies, uses three separate offsets to achieve a bubble-tight shut-off. One of the offsets applies to the location of the valve shaft relative to the centerline of the bore. Another offset is between the centerline of the disc/seat sealing surface and the shaft. Then, the third offset is the geometry of the seating surface, which creates a cone shape of the disc and seat. The combination of these three offsets gives this valve its key benefits which are as follows:

- Geometric Design: The design of the sealing components takes up a right-angle cone shape. Resulting in a cam-action and right-angled design where the sealing components are never in contact until their final degree of closing. Thus, enabling a repeatable sealing and an extended valve life because of its friction-free nature. In addition, the friction-free stroking throughout the valve allows for a relatively lower torque actuator to be used in operating this type of valve. Such a design makes it ideal for automation.

- Metal-to-Metal Seal: Because of the frictionless sealing mechanism, triple offset butterfly valves use a metal-to-metal seal. This enables a tight shutoff in high-pressure and high-temperature systems. Applications that use friction in sealing often use elastomers or soft material for the valve trim, which may deteriorate with increasing temperature or when the valve is subjected to corrosion. But with the triple offset, corrosion-resistant alloys can serve for both the valve disc and seat, to deliver zero leakage performance.

- Absence of Cavities: In a triple-offset valve, there are no cavities between sealing components. Therefore, there is no room for debris to clog and disrupt the sealing mechanism, unlike gate and ball valves. This minimizes maintenance costs and extends the valve life.

Single Offset Butterfly Valve vs Triple Offset Butterfly Valve

The single offset butterfly valve is not common in the market because it shares a lot of similarities with the concentric/zero offset valve. Below is a table highlighting the differences between the single and triple offset valves.

| Feature | Single Offset/Concentric Valve | Triple Offset Valve |

| Seal type | The valve seat is usually made from polymers or other soft materials to enable a friction seal with the metal disc. | The three offsets allow for metal-to-metal seals using alloys for both the seat and disc. |

| Seat friction | High, because friction is the basic sealing mechanism. Thus, it is susceptible to wear and results in a shorter seat lifespan. | Seat friction is insignificant because sealing is by contact pressure. As a result, the valve seat enjoys much longer operational life. |

| ANSI pressure class rating | Although this valve can deliver bubble-tight shut-off, its inferior sealing mechanism, and susceptibility to wear limit this to class 150. | Delivers dependable sealing which does not wear easily. Models such as the triple offset can achieve a 1500-pound rating. |

| Fluid services | Because of its friction sealing mechanism, it is only effective with clean fluid. | The triple offset sealing mechanism is more tolerable to dirt, so works with clean or dirty fluids. |

| Applications | Common in utilities and domestic applications. | Can function effectively in severe service and high cyclic operations. |

Double Offset Butterfly Valve vs Triple Offset Butterfly Valve

The double offset valve is an improvement of the concentric/single offset valve and provides more versatility than the single offset. Feature comparisons are noted between the double and triple below:

| Feature | Double Offset Valve | Triple Offset Valve |

| Seal type and friction | When compared to the single offset, the double offset greatly reduces friction. However, it still relies on plastic deformation for sealing. As a result, soft materials are still used for the valve seat. | Maintains metal-to-metal seal with contact pressure. |

| Fluid service | Suitable for handling clean fluids only, due to friction in its sealing mechanism. | Maintains effectiveness, even in dirty fluids. |

| Applications | Can serve in several industrial applications including water treatment, chemicals, oil and gas, and HVAC. | Also serves in industrial applications, but suits scenarios with higher operational demand. |

| Cost | Comes at a moderate cost i.e. more expensive than single offset valves but less than triple offset valves. | The specialized machining required to achieve superior sealing makes it more expensive. |