Triple Offset Butterfly Valve

Description

The Triple offset valve or triple eccentric valve features a stem that is offset on both the X and Y axis of the butterfly valve center-line. This produces a cam-like motion as the valve operates.

What is a Triple Offset Butterfly Valve?

ZECO triple offset butterfly valve adopts three-eccentric structure, which increases angle eccentricity in time on the basis of double offset butterfly valve with metal to metal seal. Angular eccentricity means that the conical axis of the sealing surface of the butterfly disc is inclined to the axis of the body cylinder. At this time, the section of the sealing surface becomes an ellipse, so the shape of the sealing surface is asymmetric. One side is inclined to the center line of the body, and the other side is parallel to the center line of the body. The main role of this angle eccentricity is to make the valve in the process of opening or closing, any point between the sealing ring and the valve seat will be quickly off or contact so that no friction between the sealing surface extends the service life of the valve.

What is Triple Offset Structure?

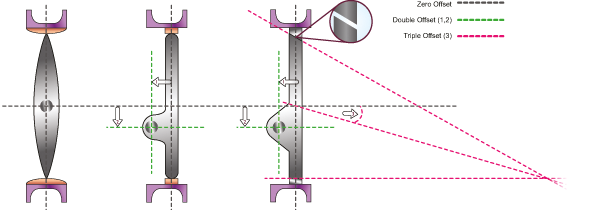

A Triple Offset Butterfly Valve has 3 separate offsets. Two of the offsets apply to the location of the shaft in respect to the centerline of the bore and the centerline of the disc/seat sealing surfaces. The third offset is the design in the axis of the seat cone angle.

Zero Offset: The disc rotates around the center axis allowing for a potential 360º rotation. Sealing is achieved by the Disc deforming the soft seal resulting in full friction through the full operating cycle.

Double Offset: To allow displacement of the seat the shaft is offset from the center line of the disc seat and body seal (offset one), and the center line of the bore (offset two). This creates a cam action during operation to lift the seat out of the seal resulting in friction during the first 10 degrees of opening and final 10 degrees of closing.

The triple offset is the geometry design of the sealing components. The sealing components are each machined into an offset conical profile resulting in a right-angled cone. This ensures friction-free stroking throughout its operating cycle. Contact is only made at the final point of closure with the 90° angle acting as a mechanical stop; resulting in no over-travel of the disc seat.

Applications of Triple Offset Butterfly Valves

Triple offset butterfly valves are efficient in applications that have special challenges such as abrasive material, high pressure or temperature, and even those that are prone to fugitive emissions.

You would find triple offset butterfly valves in applications such as steam with over 150 psi or high-temperature pure gas or liquid. In cases like these, the metal seat types without the soft coating are more economical.

These valves are often used in industries such as oil and gas processing, refining, chemical and petrochemical applications, power generation, offshore applications, pulp and paper, and so on.

Features of Triple Offset Butterfly Valve:

- ZECO triple offset butterfly valve adopts replaceable valve seat, which is convenient to replace the valve seat and sealing ring directly after the valve is removed on site in case of seat damage or maintenance, without wasting time and losing the cost of pipeline normal operation;

- ZECO triple offset butterfly valve can choose various materials for the valve body, butterfly plate, and sealing surface material according to the user’s actual working conditions to meet the user’s requirements;

- ZECO butterfly valve support is ISO 5211 standard with uniform size, which can be used at ZECO site or user site to change the desired electric, pneumatic, hydraulic, or turbine actuators;

- ZECO butterfly valve adopts a combined packing sealing system to ensure the maximum leakage of valve ≤20ppm. Users can choose the dynamic load sealing structure according to the working conditions, to extend the use time of the packing from frequent maintenance.

Material of Triple Offset Butterfly Valve:

| No | Part | Material |

| 1 | Body | ASTM A216 WCB + 13Cr |

| 2 | Seal Ring | Graphite + SS304 |

| 3 | Retainer Flange | ASTM A105 |

| 4 | Pin | ASTM A276 410 |

| 5 | Disc | ASTM A216 WCB |

| 6 | Stem | ASTM A276 410 |

| 7 | Stem Packing | Graphite |

| 8 | Stem Beating | SS304 + PTFE |

| 9 | Bolt | ASTM A193 B7 |

| 10 | Nut | ASTM A194 2H |

| 11 | Yoke | ASTM A216 WCB |