- Ball valves provide fast quarter-turn operation and tight sealing, making them ideal for frequent use and quick shutoffs.

- Gate valves require multiple turns but excel in large-diameter pipes and applications where slow opening prevents water hammer.

- For most residential and commercial uses, ball valves offer better long-term value despite higher upfront costs.

- Choose gate valves for infrequent operation in large pipelines where gradual flow control matters.

Ever stood in the plumbing aisle wondering whether you need a ball valve or a gate valve?

You’re not alone.

I’ve seen countless people scratch their heads over this exact decision. And honestly? Pick the wrong valve and you could be looking at leaks, poor flow control, or expensive repairs down the road.

The good news is that ball valves vs gate valves isn’t as complicated as it seems. Once you understand how each valve works and where they excel, the choice becomes crystal clear.

In this post, as a professional ball valve manufacturer and gate valve manufacturer, let me break down everything between ball valves and gate valves for you.

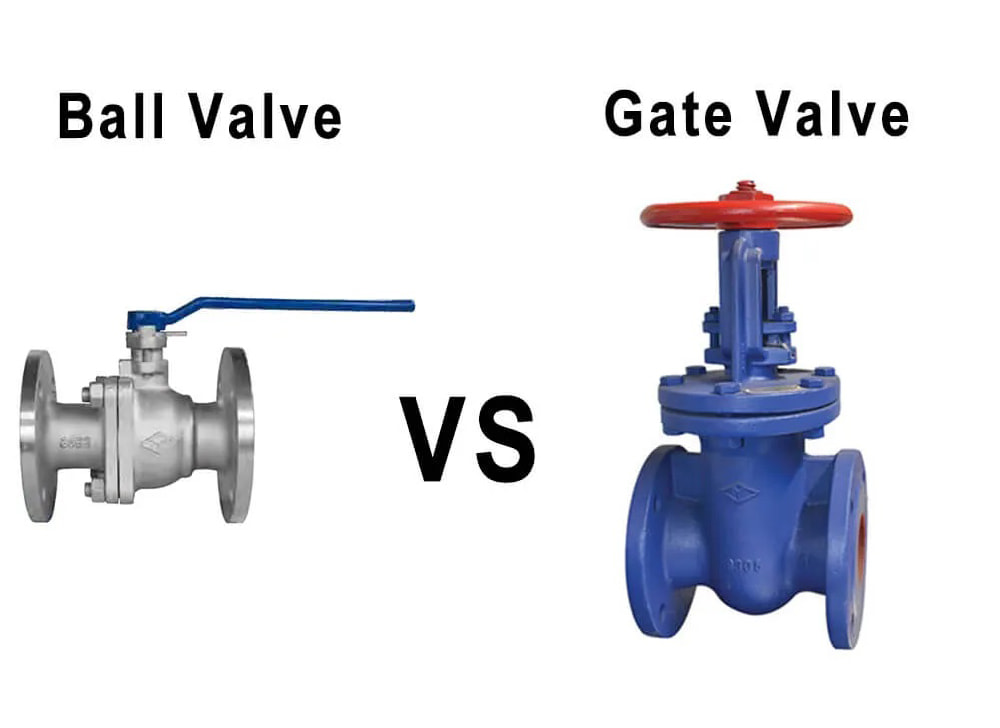

What Are Ball Valves and Gate Valves?

Before we dive into the comparison, let’s quickly cover what these valves actually do.

Both ball valves and gate valves control the flow of liquids and gases through pipes. Think of them as the on/off switches of your plumbing system.

But here’s where it gets interesting:

They work in completely different ways.

Ball Valves: The Quarter-Turn Wonder

A ball valve uses a rotating sphere with a hole through the middle. Turn the handle 90 degrees, and the hole either lines up with the pipe (open) or blocks it (closed).

Simple. Fast. Effective.

That’s why you’ll find ball valves everywhere from your home’s main water shutoff to industrial chemical plants.

Gate Valves: The Slow and Steady Option

Gate valves work more like a castle gate. A metal wedge (the gate) slides up and down to open or close the flow path.

You’ve probably used one without realizing it. That outdoor spigot for your garden hose? Classic gate valve.

But here’s the thing:

Gate valves require multiple turns to fully open or close. We’re talking 5-10 complete rotations of the handle.

Ball Valves vs Gate Valves: 4 Key Differences

Now let’s get into the meat and potatoes of this comparison.

Operation Speed: No Contest

Ball valves win this round hands down.

Quarter-turn operation means you can shut off flow in literally one second. Gate valves? You’ll be cranking that handle for 30 seconds or more.

This matters more than you might think.

Imagine a pipe bursts in your basement. With a ball valve, you can stop the flooding almost instantly. With a gate valve, you’re spinning that wheel while water gushes everywhere.

Sealing Performance: Ball Valves Take the Lead

Here’s something I learned the hard way:

Gate valves are prone to leaks over time.

Why? That sliding gate mechanism creates wear points. Add in some mineral deposits or corrosion, and you’ve got a recipe for drips.

Ball valves use a different approach. The ball rotates against PTFE (Teflon) seats, creating a bubble-tight seal that lasts for years.

In fact, I’ve seen 20-year-old ball valves that still seal perfectly.

Flow Characteristics: It Depends

When fully open, both valve types offer excellent flow characteristics.

But there’s a catch with ball valves:

Standard ball valves have a slightly smaller internal diameter than the pipe. This creates a minor flow restriction.

Gate valves? When fully open, the gate retracts completely out of the flow path. Zero obstruction.

(Pro tip: You can get “full port” ball valves that match the pipe diameter. Problem solved.)

Durability and Maintenance: Mixed Results

This one’s interesting.

Ball valves generally last longer with less maintenance. That rotating ball design means fewer wear points and less friction.

Gate valves need more TLC. The stem can corrode. The gate can get stuck. Debris can prevent proper sealing.

But here’s the flip side:

When a gate valve does fail, you can often repair it. Ball valves? Usually it’s cheaper to just replace the whole valve.

Ball Valves vs Gate Valves Cost Comparison

Let’s talk money.

Gate valves typically cost 20-30% less than comparable ball valves.

Sounds like gate valves win, right?

Not so fast.

The Real Cost Equation

Initial cost is just part of the story. Consider:

- Installation labor: Ball valves install faster (fewer connections, easier to position)

- Maintenance costs: Gate valves need more frequent attention

- Replacement frequency: Ball valves last 2-3x longer on average

- Downtime costs: Quick ball valve operation means less system downtime

When you factor in total cost of ownership, ball valves often come out ahead.

When to Use Each Valve Type

Here’s my practical guide for choosing between ball valves and gate valves:

Choose Ball Valves When:

- You need quick on/off control

- The valve will be operated frequently

- Tight sealing is critical (like with gas lines)

- Space is limited (ball valves are more compact)

- You want multi-port configurations

- Automation is required (ball valves are easier to automate)

Choose Gate Valves When:

- You’re working with large diameter pipes (8″+ typically)

- The valve will stay open or closed for long periods

- You need to prevent water hammer

- Budget is extremely tight

- You’re matching existing gate valves in the system

- Throttling or flow regulation is needed (though globe valves are better for this)

Real-World Applications

Let me share where I typically see each valve type:

Ball Valve Applications:

- Residential main water shutoffs

- Natural gas lines

- Compressed air systems

- Chemical processing

- Fire suppression systems

- HVAC systems

Gate Valve Applications:

- Municipal water mains

- Fire hydrants

- Large industrial pipelines

- Wastewater treatment plants

- Irrigation systems

- Power plant cooling systems

Installation Tips That’ll Save You Headaches

Based on years of experience, here are my top installation tips:

For Ball Valves:

- Check the flow direction – Some ball valves are directional

- Leave handle clearance – That 90-degree swing needs room

- Use thread sealant properly – But keep it off the first two threads

- Consider handle position – Make sure “open” aligns with your access point

For Gate Valves:

- Install vertically when possible – Helps prevent sediment buildup

- Never force a stuck valve – You’ll damage the stem

- Exercise annually – Open and close to prevent seizing

- Check packing regularly – Tighten or replace as needed

Common Mistakes to Avoid

I’ve seen these errors countless times:

Using ball valves for throttling – They’re designed for on/off, not flow control. The partially open position causes turbulence and seat wear.

Ignoring water hammer with ball valves – That quick closing can create pressure spikes. In high-pressure systems, close ball valves slowly.

Forcing stuck gate valves – If it won’t turn, don’t grab a bigger wrench. You’ll snap the stem.

Mixing valve types randomly – Keep your system consistent where possible. It simplifies maintenance and spare parts inventory.

Making the Final Decision

Here’s my bottom line advice:

For most residential and commercial applications in 2026, ball valves are the better choice. They’re more reliable, easier to operate, and provide better long-term value.

Gate valves still have their place, especially in large-scale industrial applications or where slow opening/closing is actually beneficial.

But when in doubt? Go with a quality ball valve from a reputable manufacturer.

The slightly higher upfront cost pays for itself through years of trouble-free operation.

The Future of Valve Technology

Looking ahead, we’re seeing interesting developments:

- Smart valves with position sensors

- Advanced materials for extreme temperatures

- Automated valve networks for building management

- Improved seat designs for longer life

But the fundamental choice between ball valves vs gate valves remains the same.

Understand your application, consider the factors I’ve outlined, and you’ll make the right choice every time.