If you’ve ever worked with fluid control systems, you’ve probably asked: do globe valves have a flow direction? The short answer is yes—and installing one incorrectly could cost you time, money, and even safety.

In this guide, I’ll break down why flow direction matters for globe valves, how to identify the correct orientation, and what happens if you get it wrong. By the end, you’ll know exactly how to optimize these valves for industrial applications, HVAC systems, and more. Let’s dive in.

Table of contents

Why Flow Direction Matters in Globe Valves

Globe valves are the Swiss Army knives of flow control. They regulate, throttle, and shut off fluids with precision. But their design has a catch: they’re directional.

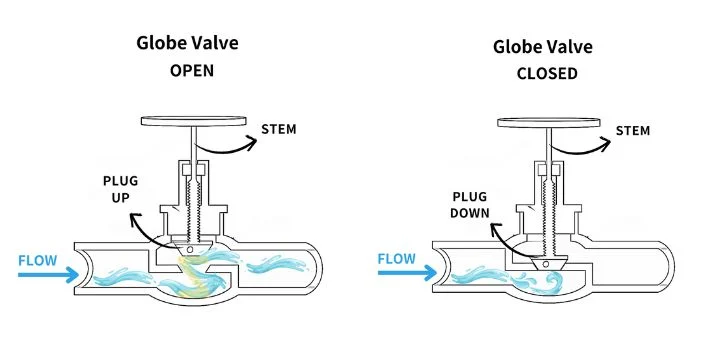

Unlike ball valves (which work equally well in any orientation), globe valves rely on a disk-and-seat mechanism. Fluid must enter from a specific side to avoid excessive pressure drop, wear, or even valve failure.

Here’s the kicker: install it backward, and you’ll sabotage its efficiency. For example, a reversed globe valve in a steam system might leak or wear out 3x faster. Not ideal.

Do Globe Valves Have a Flow Direction?

Yes, globe valves are directional, meaning they are designed to handle fluid flow in a specific direction. The direction depends on the application and whether the valve is configured as “flow-to-open” or “flow-to-close.”

Flow-to-Open vs. Flow-to-Close: What’s the Difference?

Most globe valves fall into two categories:

1. Flow-to-Open (FTO):

– Fluid enters under the disk, pushing it upward to open.

– Common in low-pressure systems (think water supply lines).

– Pros: Smooth operation, less seat erosion.

2. Flow-to-Close (FTC):

– Fluid flows over the disk, forcing it downward to close.

– Used in high-pressure or high-temperature scenarios (e.g., steam lines).

– Pros: Better sealing under extreme conditions.

Manufacturers always mark the correct flow direction on the valve body—usually with an arrow. Miss that arrow, and you’re gambling with performance.

3 Consequences of Ignoring Flow Direction

Still tempted to wing it? Here’s what could go wrong:

1. Premature Wear:

Reverse flow batters the disk against the seat, causing leaks. One study found a 40% shorter lifespan in misinstalled valves.

2. Reduced Flow Control:

FTC valves installed backward struggle to throttle accurately. You’ll see erratic pressure drops and flow rates.

3. Safety Risks:

In chemical plants, a backward valve might fail to shut off corrosive fluids. Cue spills, downtime, and OSHA reports.

How to Identify the Correct Flow Direction (Step-by-Step)

1. Look for the arrow: Check the valve body for a cast or engraved flow indicator.

2. Confirm the type: FTO valves typically have a stem that rises when open; FTC stems lower.

3. Consult the spec sheet: When in doubt, the manufacturer’s documentation always trumps guesswork.

Pro Tip: In 2025, smart valves with IoT sensors will auto-flag incorrect installations. Until then, double-check manually.

Fluid Dynamics and Valve Longevity

Understanding terms like pressure drop, cavitation, and trim design helps you master globe valves. For instance:

– A high pressure drop across the valve often signals incorrect flow direction.

– Cavitation (bubbles collapsing near the disk) accelerates erosion in FTC valves.

– Trim design (disk/seat geometry) determines optimal flow patterns.

These concepts aren’t just jargon—they’re your toolkit for troubleshooting.

FAQs: Globe Valve Flow Direction

Q: Can I retrofit a globe valve to work in reverse flow?

A: Technically yes, but expect reduced efficiency. Most manufacturers void warranties for reverse use.

Q: Do all globe valves have directional markings?

A: Reputable brands do. If yours doesn’t, upgrade to a certified valve ASAP.

Q: How does flow direction affect valve sizing?

A: Reverse flow increases the required Cv (flow coefficient). Always recalculate using the valve’s flow-to-close or flow-to-open specs.

Final Thoughts

By now, it’s clear: globe valves absolutely have a flow direction. Installing them correctly isn’t optional—it’s critical for safety, efficiency, and cost savings.

Whether you’re working with cryogenic fluids or superheated steam, always respect that arrow on the valve body. And in 2025, as systems grow more complex, this attention to detail will separate the pros from the amateurs.

Still have questions about do globe valves have a flow direction? Drop them in the comments—I’ll tackle them personally.