Non-slam check valve refers to the valve that automatically opens and closes the disc depending on the flow of the medium itself to prevent medium backflow, also known as a check valve, one-way valve, counterflow valve, and back pressure valve. Non slam check valve belongs to an automatic valve. Its main function is to prevent medium backflow, reverse pump and drive motor, and discharge of container medium.

What is a Non Slam Check Valve?

Non-slam check valves are check valves used to prevent reverse fluid flow. Also, these valves are meant to eliminate or reduce water hammer and their associated effects. A water hammer is a high-pressure shock wave that happens when the fluid flow stops abruptly because of a pump or valve closing quickly in a piping system. When water hammer happens, the fluid flow reversal causes high stress on the piping system which endangers its structural integrity and may cause damage or rupture. Non-slam check valves are used to prevent water hammers and ensure fluid flows in one direction only. Non slam check valve manufacturers produce this valve without a handle or actuator but it works mechanically to stop the fluid flow from reversing.

How does a Non Slam Check Valve work?

The opening and closing parts open or close by themselves depending on the flow and force of the medium, so as to prevent the reverse flow of the medium, the valve is called non slam check valve. Non-slam check valve belongs to automatic valves. It is mainly used in pipelines with a one-way flow of the medium. It allows medium to flow in one direction only to prevent accidents.

Types of Non-slam Check Valve

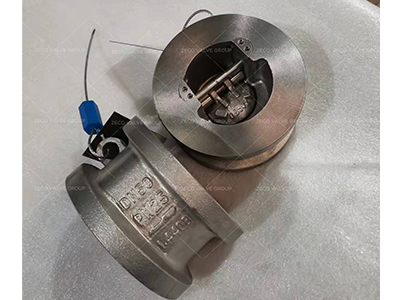

Non-slam check valves can be divided into three types according to their structure: lifting non-slam check valves, swing non-slam check valves and butterfly non-slam check valves.

- 1. Lifting non-slam check valve is divided into vertical and horizontal.

- 2. Rotary non-slam check valve can be divided into three types: single-lobe, double-lobe, and multi-lobe.

- 3. Butterfly non-slam check valve is straight-through.

The above non-slam check valves can be divided into threaded connection, flange connection, welding connection, and clamp connection.

Structure of Non-slam Check Valve

According to the structure, it can be divided into three types: lifting non-slam check valve, swing non-slam check valve, and butterfly non-slam check valve. The lifting non slam check valve can be divided into two types: vertical and direct. Rotary non-slam check valve can be divided into three types: single-lobe, double-lobe, and multi-lobe. The butterfly non-slam check valves are butterfly double-lobe, butterfly single-lobe and the above non-slam check valves can be divided into four types in connection form: threaded connection, flange connection, welding, and clamping connection.

Differences Between Non-Slam and Swing Check Valves

Some styles of check valves are specifically designed to allow their disc, or flapper, to slam shut in certain conditions, such as the reversal of fluid flow. This sudden shutting, or slamming, creates a wave of pressure in the liquid that reverberates throughout the system and, depending on the precise application, can ultimately lead to reduced process efficiency, valve damage, gasket joint leaks, and other issues. This inevitable — but controllable — phenomenon is commonly referred to as a water hammer.

Non-slam check valves are designed specifically for use in these situations. As their name implies, these valves close without slamming, meaning no excess pressure spikes are created. The disc of a non-slam check valve has an internal spring opposing the opening fluid flow pressure. When the flow of a media is strong enough, the spring compresses and the valve opens; the disc is smoothly pushed back toward the seating surface in the valve by the spring as the flow decreases and stops, but before flow direction reverses.

Often called flapper style check valves, swing check valves are a more traditional variety. The disc of a swing check valve is secured to the body of the valve by a trunnion and hinge arm, without the aid of a spring. Unlike a non-slam check valve, which opens and closes at rates comparable to the pressure of the fluid flow, a swing check valve opens and closes more suddenly, relying on the installation orientation, gravity, and reversing flow to close the valve.

Applications of Non-slam Check Valves

- Non-slam check valves are used in chemical industries.

- These valves are used in the foods and beverages industries.

- They are used in pharmaceutical applications.

- These valves are used to prevent the backflow of water or steam in boiler applications.

- They are used to prevent water contamination in the freshwater supply.

- These valves are used in the oil and gas industries.

- They are used in wastewater treatment.