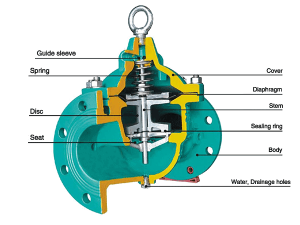

Description

Solenoid Control Valve

Festures of Solenoid Control Valve

- Small in size can replace gate and butterfly valves large electric operating system.

- The closing speed is adjustable and stable.

- Save energy

- Full port, small fluid resistance

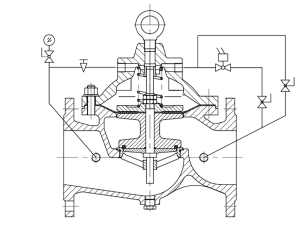

Solenoid Control Valve Working Principle

When supplying water from the inlet, water flows through the needle valve and enters the main valve control room. When solenoid pilot valve opens, the water in the control room flows out through the solenoid pilot valve and ball valve. If the ball valve opening is greater than the needle valve opening, the main valve controls the indoor pressure is very low, the main valve is in the state of full opening. The pressure in the control room increases and the main valve begins to close when the solenoid pilot valve closes, the main valve control room stops draining.

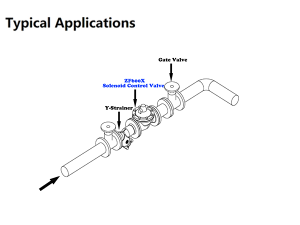

Solenoid Control Valve Installation and Commissioning

A filter should be installed before the solenoid pilot valve and should be convenient to pollution discharge. The solenoid valve can choose alternating current 220V or direct current 24V. Normally open or normally closed type can be chosen according to various occasions. For specific use, please consult ZECO Valve Group.

Solenoid Control Valve Material and Standard

Size Range: 2″~24″

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

| Part | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Bonnet | Ductile Iron | EN 1563/DIN 1693 |

| Trim | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Seat | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Diaphragm | EPDM / NBR | ISO 4633 |

| Pilot Valve | CuZn39Pb1 / C37000 | EN12167/ASTM B135 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||