The choice between a gate valve and butterfly valve is not always straightforward. Both valve types have distinct advantages and limitations that make them suitable for different applications. This article will compare gate valves vs butterfly valves to help you determine the better option for your system.

Overview: How Do Gate Valves and Butterfly Valves Work?

Before diving into the gate valve vs butterfly valve showdown, let’s go over how each valve works at a basic level.

Gate Valve Operation

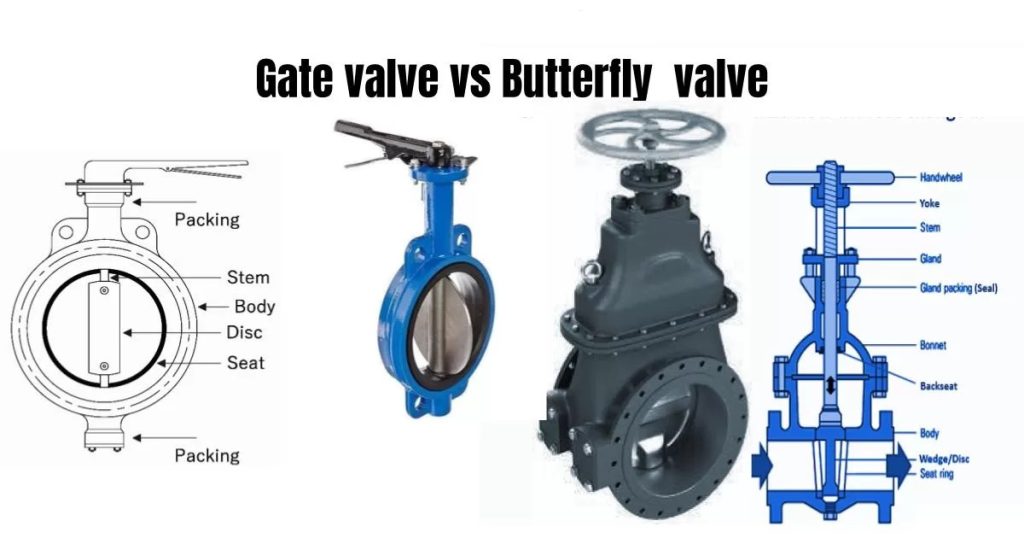

Gate valves use a vertically-moving gate to control fluid flow. When fully raised, the gate allows unobstructed, non-turbulent flow through the valve. Fully lowering the gate blocks flow completely.

Gate valves are either fully open or fully closed – partial opening can damage the valve or seating. Their relatively slow operation makes gate valves unsuitable for applications needing throttling or frequent actuation.

[Diagram showing gate valve operation with gate fully raised and lowered]

Gate valves come in a variety of designs, materials, and options for manual or automatic actuation. Key types include solid wedge, flexible wedge, parallel slide, and knife gate valves.

Butterfly Valve Operation

Butterfly valves use a rotary disc – the “butterfly” – to regulate flow. A 90 degree turn moves the disc from fully open (parallel to flow) to fully closed (perpendicular to flow).

Unlike gate valves, butterfly valves can also throttle flow accurately via intermediate disc positions. Their simple operation allows rapid, frequent actuation.

Butterfly valve designs differ mainly by disc-to-seat contact style. Common options are zero offset, single offset, double offset, and triple offset. Materials range from plastic to various metal alloys.

Comparing Gate Valves vs Butterfly Valves

Now let’s directly compare the advantages, disadvantages, and applications of gate valves vs butterfly valves.

Structural Design

Gate valves contain more components than butterfly valves. Extra parts like the bonnet, packing, and rising stem make gate valve construction more complex.

The gate valve’s moving wedge piece allows tighter shutoff than a butterfly valve’s single disc. But the disc’s direct sequent contact causes comparatively faster wear.

Gate valve design permits full bore flow. This reduces resistance and avoids flow pattern disruption. Butterfly valves inherently obstruct flow somewhat even when fully open.

Ease of Operation

Butterfly valves excel in operation speed by allowing flow adjustment via a quick 90 degree turn. Gate valves require gradual multi-turn stem winding to stroke the gate up or down.

Frequent operation tends to damage gate valves over time. Their bonnet packing can wear out, causing leakage or stem damage. Butterfly valves suffer negligible wear from cycling.

While gate valves only permit fully on or fully off flow control, butterfly valves throttle accurately across a range of openings. This gives them superior adjustability.

Reliability & Maintenance

When new, gate and butterfly valves achieve comparable mechanical reliability. But gate valves’ bonnet seal wears over time, eventually allowing leakage. This necessitates periodic seal replacement.

Butterfly valves’ unidirectional disc movement prevents backflow without a check valve. Gate valves need external backflow prevention in bidirectional applications.

Over long periods, butterfly valve discs suffer seating surface wear. Complete butterfly valve overhaul has a lower cost than rebuilding gate valves, however.

Installation Considerations

In smaller sizes, gate and butterfly valve pricing is comparable. But for large diameters, butterfly valve costs are considerably lower.

Installation space requirements favor butterfly valves too. Their compact, lightweight forms occupy less space than heavy, bulky gate valve bodies.

Butterfly valve discs pose an obstacle to pipe pigging, unlike full bore gate valves. Where pig launcher/receiver access is needed, gate valves have the advantage.

Gate Valve vs Butterfly Valve Comparison Chart

| Factor | Gate Valve | Butterfly Valve |

|---|---|---|

| Cost (Large Sizes) | High | Low |

| Weight (Large Sizes) | Heavy | Light |

| Actuation Speed | Slow | Very Fast |

| Adjustability | Fully Open/Closed Only | Accurate Throttling |

| Leakage Tendency | Bonnet Seal Wear Over Time | Resilient Seating Wear Over Time |

| Maintenance Frequency | Moderate | Low |

| Installation Space | Large | Compact |

| Flow Resistance | Minimal | Moderate |

| Pipe Pigging | Permitted | Restricted |

Choosing Between Gate Valves and Butterfly Valves

As the comparison shows, both gate valves and butterfly valves have advantageous and disadvantageous application niches. Keep these guidelines in mind when selecting either valve type:

Prefer gate valves for:

- Tight shutoff and bidirectional flow control

- Minimal flow resistance

- Allowing pipe pigging

- Large, heavy duty installations

Prefer butterfly valves for:

- Frequent cycling or throttling

- Compact installations with space limitations

- Cost/weight sensitive large diameter lines

- Unidirectional flow control

Within their operational constraints, both gate valves and butterfly valves achieve reliable flow control. Understanding their fine differences allows choosing the optimum valve technology for your application’s needs. Proper selection maximizes performance, safety and cost efficiency.

Hopefully this overview gives you a balanced perspective on the gate valve vs butterfly valve decision. Please share any valve insights or questions in the comments below!