What is Pigging?

Pipeline pigging is a process used to clean, inspect, and maintain pipelines. The term “pig” refers to a cylindrical device that is inserted into a pipeline and moved through the pipeline using the flow of fluid. The pig is typically made of rubber or other flexible materials and is designed to conform to the shape of the pipeline as it moves through it.

The pigging process typically involves inserting the pig into the pipeline at a pig launcher, which is a specialized valve or fitting that allows the pig to be inserted into the pipeline while the pipeline is in operation. The pig is then propelled through the pipeline using the flow of fluid and may be used to clean the pipeline of debris or deposits, inspect the interior of the pipeline for damage or defects, or perform other maintenance tasks.

There are several different types of pigging techniques, including batch pigging, where a series of pigs are run through the pipeline in sequence, and inline pigging, where the pig is inserted into the pipeline while the pipeline is in operation. The specific pigging technique used depends on the requirements of the application and the characteristics of the pipeline being pigged.

Why is it Called Pigging?

The term “pigging” comes from the use of a cylindrical cleaning device that resembles a pig, both in shape and behavior. These devices, which are inserted into a pipeline and moved through the pipeline using the flow of fluid, were originally made from bundles of straw wrapped in wire mesh, which was thought to resemble the appearance of a pig.

As the use of pigging devices became more common in pipeline cleaning and maintenance, the term “pigging” came to be used to describe the entire process. Today, pigging is a widely used term in the pipeline industry and is commonly used to refer to the use of any type of cleaning or maintenance device that is inserted into a pipeline and moved through the pipeline using the flow of fluid.

Pigging is a method of introducing a mechanical device, commonly referred to as pigs or scrapers, inside a pipeline to perform various internal maintenance operations. The term PIG is said to be an acronym for “Pipeline Intervention Gadget”. The process has been used for many years to scrub large-diameter pipelines in the oil and gas industry. Today, the use of smaller diameter pigging systems is growing in many continuous and batch processing plants, as plant operators are looking for improved productivity and ways to reduce costs.

What is the Purpose of Pigging?

The primary purpose of pipeline pigs is to make sure that the pipe is clean and free from obstruction. The pig is usually cylindrical or spherical to aid movement and efficient cleaning. As the pig moves through the pipeline, it can remove and possibly detect any build-ups within the pipe which can often lead to reduced performance, increased energy costs, and cause corrosion, which could lead to disastrous leaks and cracks in the pipe.

In operation, the pigging valve is opened to allow the pigging device to enter the pipeline, and the flow of fluid is used to move the pig through the pipeline. The pig may be used to clean the pipeline of debris or deposits, inspect the interior of the pipeline for damage or defects, or perform other maintenance tasks.

What are Pigging Valves?

Pigging valves, also known as pig launchers and receivers, are specialized valves used in pipeline systems for cleaning, inspecting, and maintaining pipelines. The term “pig” refers to a device that is inserted into the pipeline and moved through the pipeline using the flow of fluid, much like a cleaning pig used in the meat industry.

Pigging valves are typically installed at the beginning and end of a pipeline section and are designed to facilitate the insertion and removal of the pigging device. They may also include features such as bypass lines, drain ports, and vents, to allow for the safe and efficient insertion and removal of the pig.

Pigging valves are used in a wide range of industries, including oil and gas, chemical processing, food and beverage, and more. They are designed to withstand high pressures and temperatures and may be made of materials such as stainless steel, carbon steel, or other alloys to suit the specific requirements of the application.

How does a Pigging Valve Work?

The basic operation of a pigging valve involves opening the valve to allow the pigging device to enter the pipeline. Once the pig is in the pipeline, the valve is closed, and the pig is propelled through the pipeline using the flow of fluid. When the pig reaches the other end of the pipeline, it is caught in the pig receiver, which is the valve located at the end of the pipeline section.

One of the key features of a pigging valve is the bypass line, which is a small line that runs parallel to the main pipeline and allows fluid to bypass the valve when the pigging device is not in use. This helps to reduce pressure buildup in the pipeline and prevent damage to the valve.

Another important feature of a pigging valve is the drain port, which allows any fluid that may have accumulated in the valve to be drained away before the valve is opened. This helps to prevent contamination of the pipeline and ensure that the pigging operation is carried out safely and efficiently.

Pigging valves may also include other features, such as pressure relief valves, vent valves, and instrumentation, to help ensure the safe and efficient operation of the pigging system.

In summary, a pigging valve works by enabling the safe and efficient insertion and removal of a pigging device in a pipeline system and includes a number of features designed to ensure that the pigging operation is carried out safely and efficiently.

Pigging Ball Valve

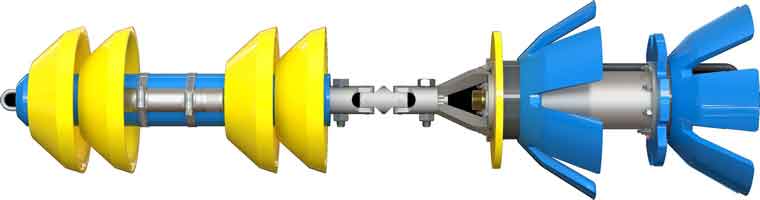

Pigging ball valves are a specialized type of ball valve that is designed for use in pipeline pigging applications. These valves are designed to enable the insertion and removal of a pigging device while also providing a tight seal when the valve is closed. The ball in a pigging ball valve is typically made from a soft material, such as rubber or polyurethane, which allows the ball to deform and conform to the shape of the pigging device as it passes through the valve.

One of the key benefits of pigging ball valves is their ability to minimize the risk of blockages or restrictions in the pipeline. The full-bore design of these valves ensures that the internal diameter of the valve is the same as the diameter of the pipeline, which helps to ensure that the pigging device can move freely through the valve and the pipeline. This can help to improve the efficiency of pigging operations and reduce the risk of damage to the pipeline.

Another benefit of pigging ball valves is their ability to provide a tight seal between the valve and the pigging device. This helps to prevent leaks and other issues during the pigging operation, which can help to ensure the safe and efficient operation of the pipeline.

Related Tags :

Ten articles before and after

Gate Valve Vs Butterfly Valve Comprehensive Compare Guide

How to Measure Butterfly Valves

What is a Double Offset Butterfly Valve

How to Fix a Leaking Butterfly Valve?

Considerations in Selecting Industrial Heat Exchangers | Zeco Valve Blog

Zeco VFlo: V-Notch Segmented Ball Control Valve | Zeco Valve Blog

Duo-Chek Check Valves Compared to Conventional Swing Check Valves | Zeco Valve Blog

Happy Labor Day from Zeco Valve! | Zeco Valve Blog

The CCS DualSnap 6900GE Industrial Pressure Switch | Zeco Valve Blog