As a professional check valve manufacturer, a common question I get from readers is: “Is a check valve the same thing as a backflow preventer? Or are they totally different?”

Great question. And in this post, I’m going to break things down in simple terms so you fully understand the difference between these two devices.

Spoiler alert: While check valves and backflow preventers serve a similar purpose (preventing reverse flow), they work differently. And backflow preventers offer more comprehensive protection.

Let’s start with the basics…

Introduction of Check Valve and Backflow Preventer

What is a Check Valve?

A check valve (sometimes called a one-way valve) is a device that allows fluid to flow in only one direction through a pipe.

For example, check valves are often used:

- On the outlet side of pumps to prevent reverse flow back into the pump

- In compressed air systems to prevent air from flowing backwards

- In plumbing systems to stop drainage from flowing upwards

Here’s a simple example:

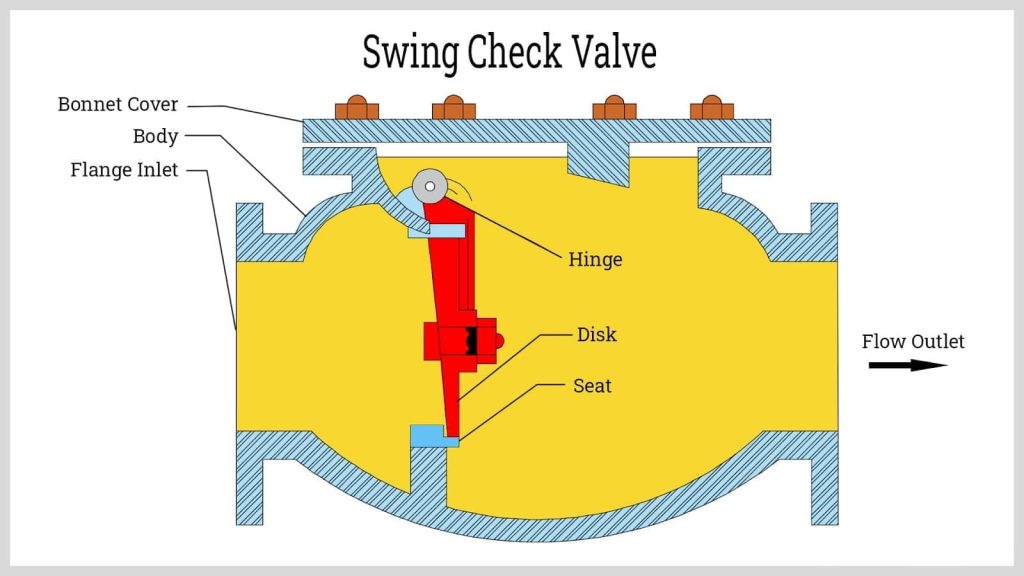

The key part of a check valve is a disc, flap, or ball that can seal off the valve.

When pressure pushes the fluid in the “forward” direction, the disc/flap opens, allowing flow. But if the flow tries to reverse, the disc is forced against the valve seat, blocking flow in the opposite direction.

So in summary:

- A check valve uses a disc, flap, ball or other method to ensure flow can only occur in one direction

- They open fully to allow forward flow, and seal closed to stop reverse flow

- Check valves are common in pumps, plumbing, compressed air systems, etc

Now let’s look at backflow preventers…

What is a Backflow Preventer?

Like check valves, backflow preventers ensure fluid can only flow in one direction in a pipe.

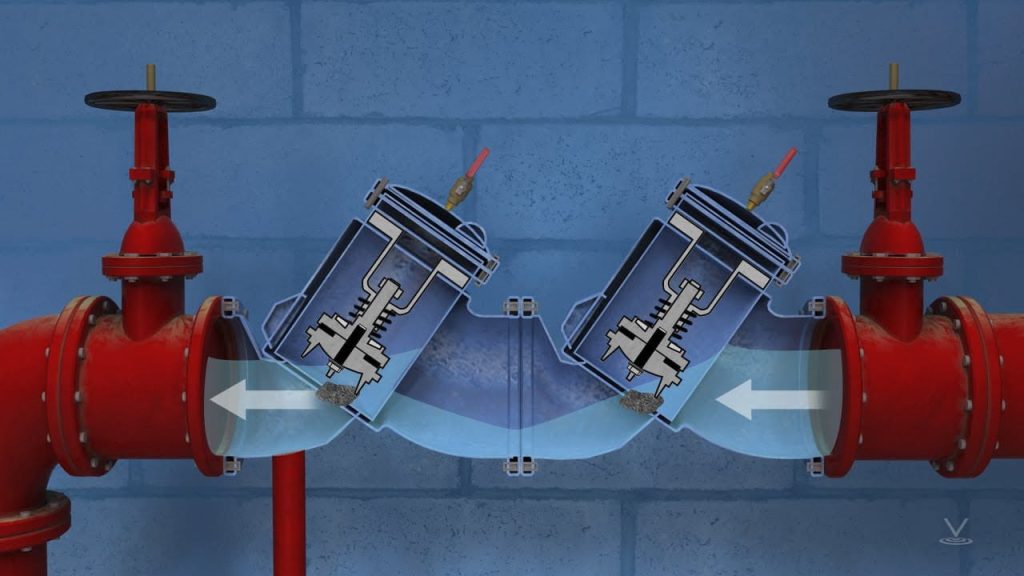

But unlike a basic check valve, backflow preventers use multiple check valves and other mechanisms to create several layers of protection against reverse flow.

For example, a typical backflow assembly has:

- Two independently operating check valves

- A pressure relief valve downstream of the checks

- Test ports to validate performance

The reason backflow preventers have MORE protection comes down to safety.

Specifically, backflow preventers safeguard potable/drinking water supplies from contamination.

For example, backflow from a fire suppression system could introduce chemicals from the sprinkler system into the drinking water system. And that would be very unsafe.

So local plumbing codes often require backflow preventers when there is a cross-connection between potable water and another system containing non-potable water or chemicals.

In summary:

- Backflow preventers contain two check valves (or more) plus relief valves

- Designed specifically to protect drinking water from contamination

- Required by code when there is a connection between potable and non-potable sources

So while check valves offer simple backflow protection, backflow preventers take it to another level for safety-critical applications like drinking water systems.

Now that we’ve covered the basics of each type of device, let’s look at some key differences in more detail…

Is a Check Valve the Same as a Backflow Preventer?

The short answer is no. Although check valves and backflow preventers serve similar functions and look similar, they work differently and have distinct applications. Though a basic check valve blocks backflow, a backflow preventer provides enhanced protection against reverse flow, especially for health hazards or cross-contamination.

Specifically engineered for preventing dangerous and high-risk backflow conditions, backflow preventers contain a combination of redundant check valves, vents, and/or relief ports for greater security. While check valves have their purpose, they should NEVER be used in place of a backflow prevention device when protecting potable drinking water systems.

5 Key Differences Between Check Valves and Backflow Preventers

There are 5 main ways that check valves and backflow preventers differ:

1. Purpose and Criticality

A check valve’s purpose is to prevent reverse flow in systems where backflow would be problematic. But check valves aren’t designed to guard against contamination or health hazards.

Backflow preventers have the specific purpose of keeping drinking water or other critical fluids safe from contamination. The stakes are higher, so backflow preventers have extra layers of protection.

2. Design and Components

As discussed earlier, check valves just use a sealing disc, ball, or flap to stop reverse flow. This straightforward, reliable design makes check valves inexpensive.

Backflow preventers contain multiple check valves, vent openings, pressure relief valves, and other components to create redundancy. This complexity costs more but offers greater backflow protection.

3. Installation Requirements

Check valves are commonplace components installed at the discretion of engineers or plumbers when backflow prevention is needed.

Backflow preventers must be installed according to plumbing codes and local water authority regulations in high-risk potable water connections. Annual testing and inspection is also typically required.

4. Application Suitability

Check valves suffice for basic backflow prevention in systems like pumps, compressors, or non-critical installations.

Backflow preventers are mandated for high-hazard situations where contamination could jeopardize drinking water. This includes connections between potable water supplies and fire sprinklers, irrigation systems, or industrial piping.

5. Reliability and Maintenance

The simplicity of check valves makes them generally reliable. But issues like wear, debris, or water hammer can overwhelm a single check valve and lead to failure.

While complex, backflow preventers are designed to operate reliably for years. Their redundancy means contaminants have less chance to bypass protections. More scrutiny is placed on proper installation and testing as well.

Real-World Examples of Check Valves and Backflow Preventers

Let’s look at some real-world examples of how check valves and backflow preventers are applied:

Check Valve Examples

- Pump Protection – A swing check valve installed on a pump outlet prevents water from flowing backwards through the pump when it shuts off

- Plumbing – An inline spring-loaded check valve allows drainage to flow one-way down a vertical pipe in an apartment building

- Compressed Air – A ball check valve stops air flowing backwards through an air compressor after compression stops

Backflow Preventer Examples

- Fire Protection – An RPZ backflow preventer between city water mains and fire sprinklers prevents contaminated water from entering city potable supplies

- Irrigation Systems – Reduced pressure backflow preventers installed at water connections leading to commercial irrigation systems avoid chemical contaminants from entering potable water sources

- Industrial – Double check valve backflow preventers placed at the intake points for plant process water systems protect the public drinking water distribution from high-hazard chemical mixtures

So in summary:

Check valves = Basic backflow protection

Backflow preventers = Critical protection of drinking water

How Do You Choose? Check Valve vs Backflow Preventer

Deciding whether a check valve or backflow preventer is needed depends mainly on two factors:

- How critical it is to avoid contamination – is it a human consumption / potable system?

- Does local plumbing code require backflow protection for your specific application?

Here’s a decision diagram:

If avoiding contamination is PARAMOUNT (like in drinking water systems), backflow preventers are your only option.

For non potable systems, check valves may suffice depending on codes and individual site assessment.

Your best bet is to consult local plumbing codes and water authorities if you’re unsure. They’ll dictate minimum backflow requirements.

Wrapping Up

While check valves and backflow preventers serve the same basic purpose of preventing flow reversal, backflow preventers are designed with drinking water protection in mind.

Mandated by plumbing code for cross-connections with water mains, backflow preventers offer maximum security through redundant check valves, relief valves, and other fail-safes.

Hopefully this gives you a solid grasp on the differences between check valves and backflow preventers. They both stop backflow, but backflow preventers are purpose-built to halt contamination in high-risk drinking water systems.