ZECO Valve is one of well-known forged steel gate valve manufacturers for oil companies and industrial industries. Forged steel gate valves are named after the fact that their body covers are made of forged materials, and their materials cover ASTM A105, ASTM A182 F11, ASTM A182 F5, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L and so on. The forged steel gate valve is usually smaller than 2 inch, but due to its high-pressure resistance, the pressure pound class can be CL2500, and the working temperature can reach -29℃ to -500℃. It is widely used in oil and gas pipelines and other industrial fields.

What is a Forged Steel Gate Valve?

Forged valves are created using a forging method that involves shaping metals and alloys while they’re in their solid form. Forged valves have a reputation for being strong, which make them ideal for handling high-pressure and high-temperature systems.

OS&Y gate valves are specifically design to industry standards for straight thru, bi-directional flow which results in low flow loss and low pressure drop. They are designed for applications where excellent flow conditions and tight shut-off are necessary. Our gate valves proudly service the oil/gas refining, pulp and paper, power generation and chemical/petrochemical industries worldwide.

We offer both Cast API 600 and Forged API 602 Gate valve designs in a wide range of sizes, pressure classes and materials to fit even the most unique and rugged applications.

Specifications of Forged Steel Gate Valves

- Model No: Forged

- Size: 3/8 to 4 inches

- Rating: 800 to 2,500 lb

- Design: API602, ANSI B16.34, BS5352, GB/T12224, GB/T12228, GB/T12234

- Socket welding end: ANSI B16.11, JB/T175-95

- Screw end: ANSI B1.20.1(NPT), GB/T7306-87(RC)

- Butt welding end: ANSI B16.25, GB/T12224

- Flange end: ANSI B16.5, JB/T82.1 to 82.4-94

- Face to face of flanged valves: ANSI B16.10, JB/T97-95

- Construction: BB or WB, OS and Y

- Test: API598, GB/T13927, JB/T9092

- Body materials: A105, LF2, F5, F11, F22, F304, F316, F304L, F316L, F347, F321, F51, Monel, Alloy20

Design Features of Forged Gate Valve

- Outside Screw and Yoke(OS&Y)

- Two Piece self aligning packing gland

- Bolted bonnet with spiral-wound gasket

- Integral backseat

- Full Port or Regular Port

- Extended Stem or Below Seal

- Welded Bonnet or Pressure Seal Bonnet

- Locking Device upon request

- Manufacturing to NACE MR0175 upon request

Components of Forged Gate Valve

- BODY

- The body is forged steel and designed to the basic dimensional requirements of the applicable specifications such as API 602 and ASME B16.34. The body is available in both the full or standard port design.

- BONNET

- The bonnet is forged steel, has an integral backseat and incorporates the stuffing box, which has dimensions per the applicable specifications such as API 602.

- BODY-BONNET JOINT

- Two different bonnet joint designs are available. These are either the bolted bonnet or the threaded and seal welded type.

- GASKET

- The bolted bonnet joint design valve uses a contained, controlled compression, spiral wound type gasket.

- BONNET BOLTING

- The bonnet bolting is manufactured of alloy steel in accordance with the requirements of the applicable specifications such as API 602 and ASME B16.34.

- SEAT RINGS

- The seat rings are steel and makeup part of the valve trim. They are pressed into the valve body and wedged into place, forming a seal with the body. The seating surfaces are ground and lapped.

- WEDGE

- The wedge, which is solid design, is forged or investment cast steel and is part of the valve trim. The seating surfaces are ground and lapped.

- STEM

- The stem is forged steel and part of the valve trim. It contains an integral back seat shoulder, which mates with the integral backseat of the bonnet. The stem is designed to the basic dimensional requirements of the applicable specifications such as API 602.

- GLAND AND FLANGE

- The gland, gland flange assembly utilizes a separate, two piece design. This self aligning design allows the flange to be unevenly tightened while the gland maintains it’s parallel alignment with the stem and stuffing box.

- GLAND BOLTS AND NUTS

- The steel/stainless steel gland bolt and nut assembly is a stud, double nut arrangement. This design allows complete removal from the valve when service is required. The use of industry standard thread full length studs and nuts also allows easy replacement should these items be lost or in need of replacement.

- YOKE SLEEVE

- The yoke sleeve is of forged stainless steel material having a high melting point and is resistant to wear and corrosion.

- HANDWHEEL

- The handwheel is forged carbon steel of an open spoke design. This robust construction along with appropriate sizing allows for ease of operation.

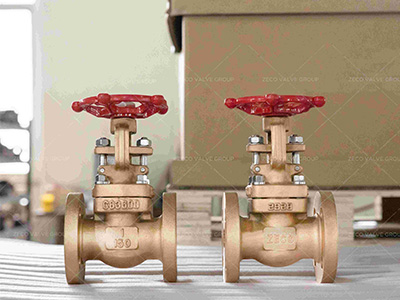

Forged Steel Gate Valve for Sale

ZECO valve adopts international standards to design forged steel gate valves. Absorbing foreign excellent forged steel gate valve design structure; Forging steel gate valve test, performance inspection in strict accordance with international standards; Absorb foreign advanced production technology experience to pay attention to the research and application of new materials; Making clear the technical parameters and working conditions of imported high-parameter valve products is the way to accelerate the process of localization, promote valve products to be constantly updated and fully realize the localization of valves. Gate valves processed by forging materials are collectively referred to as forged steel gate valves. Forging materials of forged steel gate valves include A105, F11, F5, 304, 304L, 316, 316L, etc. The forging steel gate valve usually refers to the small diameter forging steel gate valve, the diameter range: DN10~DN50; Pressure range: national standard PN16~PN320, American standard: Class150 ~ 2500, can adopt American standard or national standard size production and processing, manufacturers have spot supply. The forged steel gate valves exceeding DN50 caliber need to be customized, and the domestic demand is less. For a long time in the market, the use of the general forging steel gate valve is widespread leakage or rust. Using European high-tech rubber and valve manufacturing technology of resilient gate valves, overcome the general forged steel gate valve seal bad, rust and other defects, forged steel gate valve sealing of the elastic base seat using elastic disc produce elastic deformation compensation effect to achieve the good sealing effect, sealing off the elastic base seat forged steel gate valve has a light switch, reliable sealing, good elastic memory and service life, etc. Can be widely used in tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electric power, ships, metallurgy, energy systems, and other body pipelines as a regulator and closure device.

Advantages of ZECO Forged Steel Gate Valve

ZECO forged steel gate valve is equipped with a reduced diameter design. Compared with a cast steel gate valve of the same diameter, the medium flow rate is slightly smaller, but the pressure and temperature tolerance range are much higher. Meanwhile, ZECO can also produce full-diameter designs for users. ZECO forged steel gate valve has three types of valve body bonnet connection, the most common is the first bonnet bolt connection also commonly known as the BB structure, the seal between the body covers is wound gasket seal, this structure is convenient for maintenance, in special cases of the valve need maintenance, disassemble the bonnet can be online maintenance; The second is the body bonnet by welding way, body and bonnet welded seal without leakage point; The third is the pressure self-tightening bonnet, bonnet, and bonnet using thread connection, internal pressure self-sealing ring seal, through the use of high pressure working conditions, the greater the pressure, the better the sealing effect.