A 3 piece ball valve is preferred wherever regular cleaning is required.

What is a 3 Piece Ball Valve?

Ball valves come in one, two, or three pieces. One piece ball valves are inexpensive and generally not repaired. Two piece ball valves consist of two separate pieces, with the connection between them being either threaded or a bolt and flange assembly.

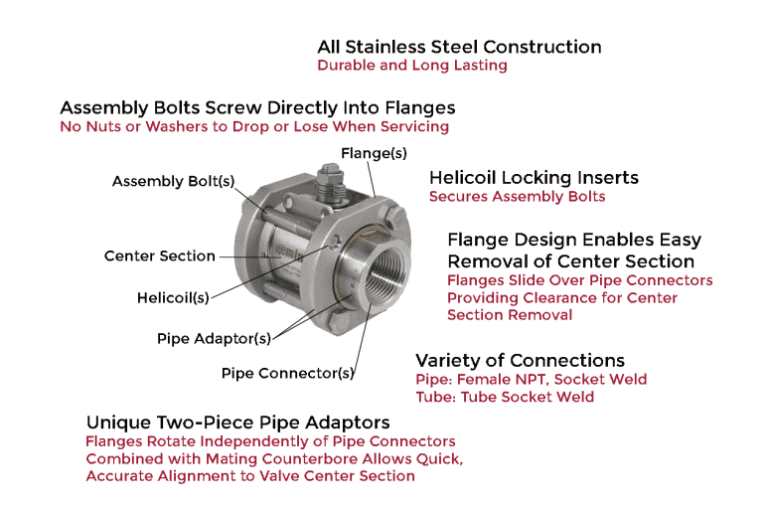

As you may have guessed, a 3 piece ball valve consists of three pieces, two end caps and a body. The end caps are welded, threaded, or flanged to connect to the pipe on either side.

Construction of 3 Piece Ball Valves

Three-piece ball valves are manufactured with one main body and two pipe connectors. The pipe connectors are typically threaded or welded to a pipe. This enables the main body to be easily removed for cleaning or repairs without having to remove the pipe connectors. Full port and bidirectional shutoff options are also available.

After installing a 3 piece ball valve, wear components — such as balls, ball seats and stems — can be replaced quickly and independently. The biggest benefit here is that the valve can remain in service for its intended lifecycle while operators enjoy low long-term maintenance costs.

Why using a 3 Piece Ball Valve?

For processes that put heavy demands on valves, having a 3 piece valve is more convenient than one or two piece ball valves. When seats and seals need to be routinely replaced, having three pieces allows for easy disassembly, servicing and reassembly without having to do major cutting on the pipe.

Three piece ball valves also allow for elastomers to be changed to accomodate different process conditions, temperatures, pressures and flows.

Need to weld the valve in place? Another benefit is being able to move the body with trim out of the way while welding, ensuring the internals stay intact.

Features of 3 Piece Ball Valves

- Fully Encapsulated End Screws. These valves are designed with cap screws that hold each end cap in place instead of the long bolts, washers and nuts like most other 3-piece valves. Because the screws are fully encapsulated, they are protected from the outside environment. They enable perfect alignment of the seat with the ball, even during field repair.

- Weld-In-Place End Caps. Another unique feature is the weld-in-place end cap with heat-dissipating rings. These end caps allow customers to weld the valve in line without removing the center body, saving on material and labor costs.

- In-Line Repair. You can repair 3-piece valves without complete removal from the line, unlike 1- and 2-piece ball valves. Simply remove three of the four cap screws on each side, and the body swings out for replacement of the seats and seals.

- Protected Seat. The Tri-Pro Series valves also feature a protected seat and encapsulated body seal design. This isolates and protects the seats and seals from the flow path, preventing cold flow and allowing long-term performance in demanding applications.