The design, construction, and function of a ball valve are generally well understood in the industrial fluid processing arena. Ball valves provide reliable quarter turn operation, compact form factor, and tight shutoff capability, making the ball valve a preferred choice for many applications. Some ball valves also provide shutoff of fluid flow in either direction. A primary valve trim design feature permits the grouping of the many variants of industrial ball valves into two categories, distinguished solely by the way in which the ball is mounted in the body.

Structure of Trunnion vs Floating Ball Valve

A trunnion ball valve consists of a ball mounted on a trunnion on the bottom and joined to a stem at the top. These parts are often welded together which is why this type of valve is sometimes referred to as a trunnion ball valve or a fully welded trunnion ball valve. Given as the ball is mounted and experiences less friction and media pressure force, this valve requires less torque to operate.

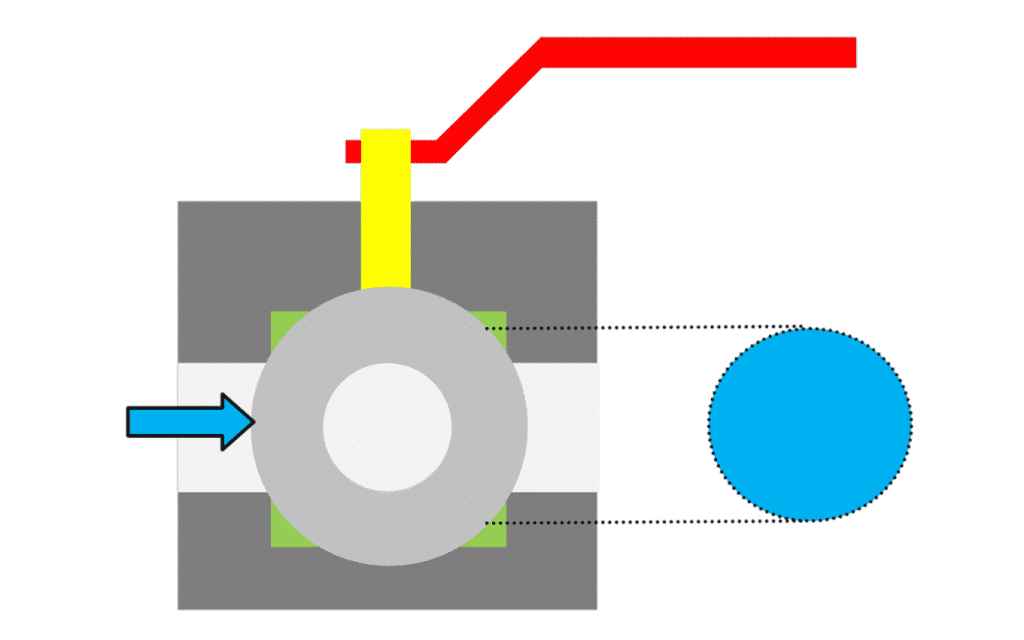

A floating ball valve, on the other hand, comprises a ball linked to a stem at the top but floats freely at the bottom. It is held in place by fluid pressure and seat rings as opposed to being mounted on a trunnion. As such, it requires high torque to operate. It is, nevertheless, a reliable bi-directional shut-off valve.

Design of Trunnion vs Floating Ball Valve

The name “floating” ball refers to the fact that the ball is suspended in the flowing medium held in position by the compression of the two elastomeric seats against it. The shaft is connected to a slot at the top of the ball which allows the ball to be driven to travel through a quarter turn (90 degrees). The shaft allows for a certain amount of lateral movement of the ball that is generated from the upstream pressure acting against the ball. This small lateral movement in fact produces a load on the ball that presses it against the downstream seat. This type of ball valve design is therefore capable of bi-directional shut-off.

The trunnion ball design in effect addresses this problem where in effect the shaft, ball, and trunnion act as a single assembly that supports the ball instead of the seats, and the seats become “floating” in a kind of reversal of the “floating ball” design. Similarly, trunnion mounted ball design is also capable of bi-directional sealing.

Floating Ball Valve vs Trunnion

Floating Ball Valve

- The valve seats are fixed in the valve body

- In the closed position, the ball can move a little bit in flow direction

- The ball is pressed against the downstream seat

- The system pressure acts on the whole circular area of the ball

Big Area – Big Force

Trunnion Ball Valve

- The ball is fixed in position by trunnions (bearing) and can only rotate

- The seats can move a little bit in flow direction

- The upstream seat is pressed against the ball

- The system pressure acts on the circular ring of the upstream seat

Small Area – Small Force

Floating ball valves use the seats and body to hold the ball in place within the fluid flow path, with the force of directional flow pushing the ball against the downstream seats to produce a tight shutoff seal. Many floating ball valves are capable of flow shutoff in either direction. The ball is rotated by a shaft connected at the top which extends through the pressure enclosure of the valve for connection to a handle or automated actuator. The floating nature of the ball limits the applicability of this design to smaller valve sizes and lower pressures. At some point, the fluid pressure exerted on the ball surface can exceed the ability of the seats to hold the ball effectively in place.

Trunnion mount ball valves employ the stem shaft and, you guessed it, a trunnion to rigidly position the ball within the body. The shaft and trunnion, connected to the top and bottom of the ball, establish a vertical axis of rotation for the ball and prevent it from shifting in response to flow pressure. The trunnion is a pin that protrudes from the bottom side of the ball. It sits within a bearing shape, generally cylindrical, at the base of the body.

Related Tags :

Related Tags :

Ten articles before and after

Pressure Measurement Using Isolation Ring | Zeco Valve Blog

Breathing Air Purifiers | Zeco Valve Blog

Thermodynamic Steam Traps | Zeco Valve Blog

Thermocompressor Breathes New Life into Low Pressure Waste Steam | Zeco Valve Blog

Orifice Plate – Primary Flow Element | Zeco Valve Blog

Ball Sector Valves | Zeco Valve Blog

Refinery Explosion Analysis and Animated Video Reenactment | Zeco Valve Blog

Wet Bulb Temperature and Cooling Tower Performance | Zeco Valve Blog

When to Use a Globe Valve for Fluid Process Control | Zeco Valve Blog

Forced Draft Cooling Tower With 20 Year Warranty | Zeco Valve Blog