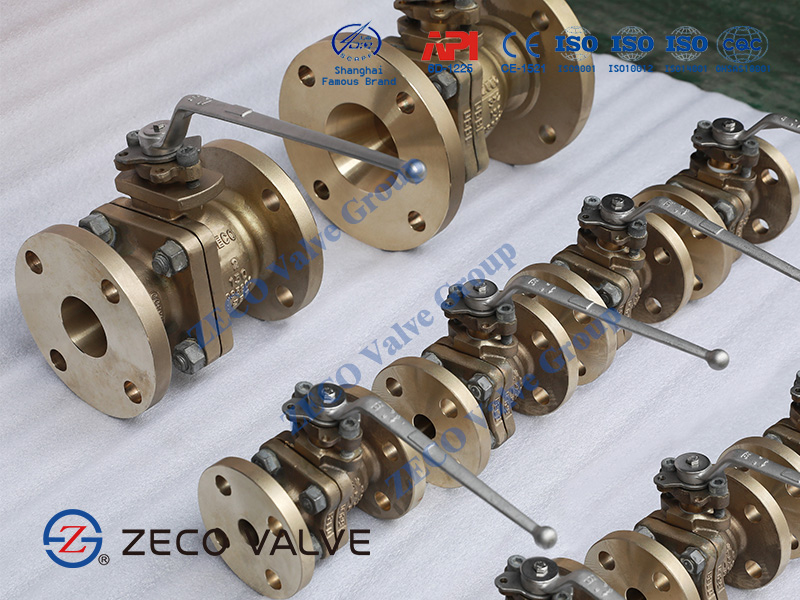

Floating Ball Valve

Description

In the world of valves, ball valves are known for their compact, durable design and reliable, fast-acting on/off control. Ball valves utilize a ball with a hole (known as a port) drilled through the center to control the flow of media. The ball is rotated 90 degrees to align the port with the valve body and allow media to flow through the valve. To close the valve, the ball is rotated 90 degrees back to the closed position. All ball valves rely on the use of two seats, usually made of polytetrafluoroethylene (PTFE), to hold the ball in place and create a tight seal to prevent media from leaking through the valve.

What is a Floating Ball Valve?

Floating and trunnion are two basic types of ball valve designs.

Floating ball valves are the most common type of valve used in industrial piping systems. These valves are designed so that as the seats begin to wear the pressure from the media flowing through the valve will force the ball against the downstream seat to maintain a tight seal.

ZECO floating ball valve has two seats supporting the ball. Under medium pressure, the ball can be pressed tightly to the sealing surface for sealing at the outlet end.

In floating ball valves, the ball is pushed against the downstream seat by the in-line pressure, resulting in tightness.

In trunnion ball valves, the ball is fixed in place by bearings that prohibit it from floating downstream. A spring-loaded seat mechanism ensures that the valve remains leak-tight as the seat inevitably begins to wear down.

How does a Floating Ball Valve work?

The shaft of floating ball valve is connected at the top of the ball and allows the switch from an open to a closed position with a quarter turn movement (90 degrees). When the shaft is moved, a load is applied to the ball which gets pressed against its seats.

When operated from closed to open position, the ball is to be rotated against both the in-line pressure (∆p) and the friction of the seats. In other words: the torque needed to operate the valve is created by both in-line pressure and the nature of the valve seats. The amount of torque required increases significantly when operating pressure (∆p) and/or valve size increase, and/or whenever the nature of the seat is made more robust. The latter applies in the case of a metal seated valve design.

This design, which is lightweight and economic, suits bore sizes up to 10 inches: above this bore size, the seats of the valve would not be able to withstand heavier and heavier balls and the valve would not operate safely and efficiently.

Floating Ball Valve Standards

| Design | API 6D, API 6DSS, ASME B16.34, ISO 14313, ISO 17292 |

| Design pressure | ASME B16.34, EN 1092-1, ISO 17292 |

| Body wall thickness | ASME B16.34, ASME VIII Div. I, ISO 17292 |

| Face to Face | API 6D, ASME B16.10 Long pattern |

| Temperature range | -50° to 200°C (-58° to 392°F) |

| Pressures range | PN10 (ANSI 150) to PN420 (ANSI 2500) |

| Size range | DN15 (1/2″) to DN250 (10″) |

| End connections | ASME B16.5 Flanged RF, FF, RTJ ASME B16.25 Butt-Weld BW ASME B16.11 Socket-Weld SW ASME B36.10 Plain-End PE ASME B1.20.1 Threaded NPT (F/M) |

Advantages of Floating Ball Valves

- ZECO floating ball valve has the function of indicating a switch. The ball, stem, and handle are the moving parts of the floating ball valve. ZECO design changes the top of the stem into a flat square structure, This provides a clear indication of the valve in the open position during service when the handle is parallel to the line; When the handle is perpendicular to the line, indicates that the valve is closed;

- ZECO floating ball valve is equipped with a locking device. ZECO adds two limit screws in the packing gland and coordinates the switch locating tab with a lock hole to ensure the damage to the valve caused by excessive opening, On the other hand, it is guaranteed that the valve can be locked in the fully open or fully closed state and cannot be operated by other personnel wrongly;

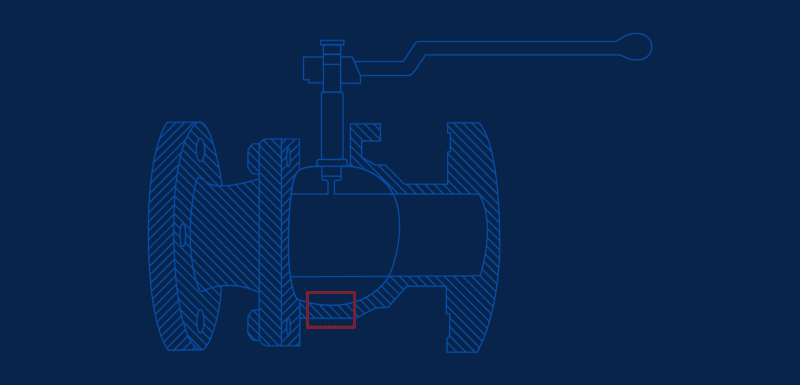

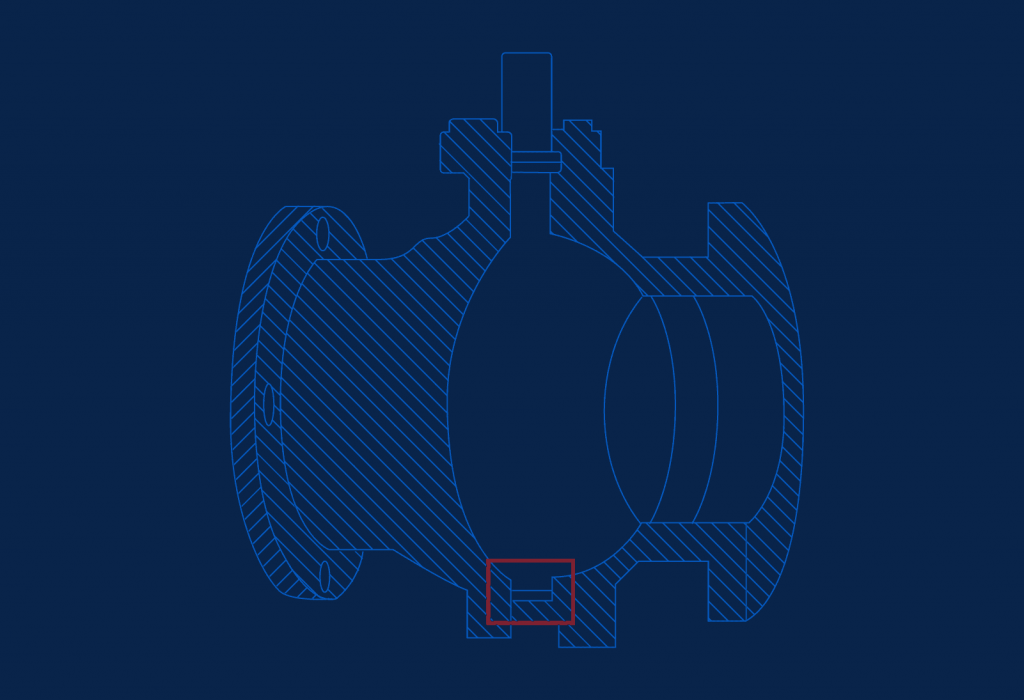

- ZECO floating ball valve with the valve stem blow out proof structure, in order to prevent the maintenance of the valve, the pressure of the medium to stem the damage to the maintenance personnel, ZECO set a convex platform at the bottom of the stem structure, on the one hand, to ensure the stem will not be out of the body, on the other hand, ensure even packing damage, the valve stem convex sets and close contact between the body and will not lead to a medium-large leaking out;

- ZECO floating ball valve is equipped with the anti-static device, friction between the ball, PTFE, and other non-metallic materials will generate electrostatic accumulation on the ball, without preventing the danger of electrostatic spark caused by the working condition, ZECO set up an anti-static device at the valve stem, which can export the static electricity through the valve stem.

Disadvantages of Floating Ball Valves

- Complete reliance on downstream seating when carrying a medium load.

- Difficult to operate when upstream pressure is high.

- Seating directly absorbs the ball’s gravity, so is unable to reliably withstand higher pressures or larger balls.

Applications of Floating Ball Valve

- Emergency shut-off systems- pipeline systems such as those involving fuels, water, or critical gases often require a fast-responding shut-off valve in case of emergencies. Given as this type of ball valve is unmounted, it works fast and is therefore suitable for SIL 3 emergency shut-offs.

- Water systems- water distribution systems require that pressure is maintained at optimum levels to sustain flow and prevent air pockets from restricting the flow of water. The flow of water also needs to be controlled to prevent overflows. A floating ball valve would be a good choice for water system control as it is pressure-sensitive and can open and shut as needed based on pressure conditions.

- Pipeline pressure relief– pipeline pressure management is essential to avoid busts and similar mishaps. A floating ball valve can be added in a pipeline as a pressure outlet valve as it takes on the pressure while remaining intact as opposed to a mounted ball valve that could sometimes blow out.

Material of Floating Ball Valve:

| No | Part | Material |

| 1 | Body | ASTM A216 WCB |

| 2 | Bonnet | ASTM A216 WCB |

| 3 | Ball | ASTM A105 |

| 4 | Seat | ASTM A105 + PTFE |

| 5 | Stem | ASTM A182 F6a |

| 6 | Anti-static Device | SS304 |

| 7 | Gasket | Graphite + SS304 |

| 8 | Bolt | ASTM A193 B7 |

| 9 | Nut | ASTM A194 2H |

| 10 | O-ring | Viton A |

| 11 | Lever | ASTM A216 WCB |