What is a Gate Valve?

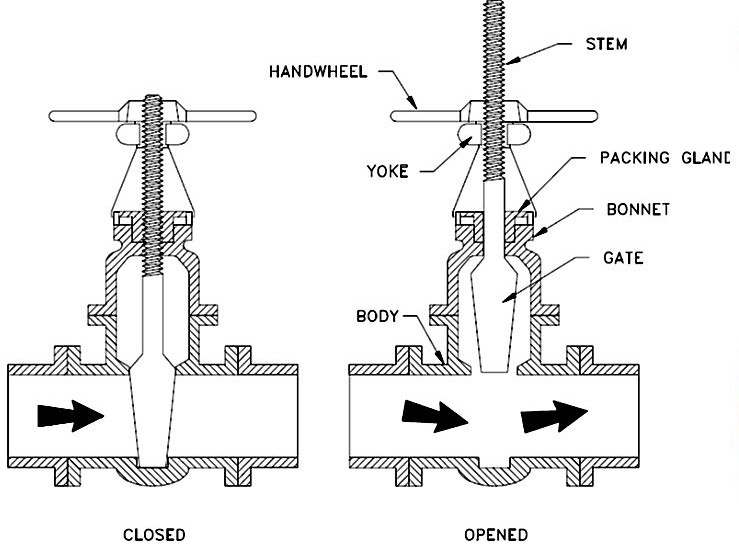

Gate valves, also known as sluice and shut-off valves. They are usually operated using a circular handwheel which when turned can lower or raise the valve gate to control the flow of medium.

Gate valve is the most common valve used in water, oil and gas supply systems. It is a linear motion isolation valve that is capable of stopping or allowing flow. These valves should not be used to regulate flow; they should be used to open fully or close completely, as partial opening can cause injury. The name ‘gate valve’ comes from the fact that the closing section slides into the flowing fluid to create a shut-off and therefore acts as a gate. Gate valves are used to isolate specific parts of the pipeline network for maintenance, repair and new installation operations, as well as to redistribute the flow of media throughout the pipeline.

Gate valves are typically used for larger pipe diameters, from 2″ to the largest, as they are less complex to construct than other larger sized valves. Gate valves are available in a variety of sizes, materials, temperature and pressure ratings, as well as gate and bonnet designs. There are gate valves with electric and pneumatic actuators, however manual gate valves are more cost effective as they are not used as often.

The gate valve is one of the most frequently used valves today due to its simple design and ability to be used in a variety of low pressure drop applications. Gate valves are designed to be full bore. This indicates that the valve port is the same size as the inner diameter of the connecting pipe. The full bore gate valve allows fluid to flow without being blocked and without causing a pressure drop in the pipe. This also makes it possible to use a cleaning pig to clean the pipe.

What is a Ball Valve?

Ball valve, also known as a shut-off valve valve. Ball valves use a handle to control the position of a ball with a hole in the mechanism. When the handle is turned, the hole immediately opens or closes the flow of water.

You can tell whether a ball valve is open or closed by the position of the handle: when open, the handle is flat and aligned with the flow of water, when closed, the handle is perpendicular to the flow of water.

Ball valves, as the name suggests, use a rotatable ball with a hole to control the flow of liquids and gases from one opening to the other. The medium can flow through, or be stopped by turning the ball a quarter turn (90 degrees) about its axis. These valves regulate the flow by allowing the opening to be opened, blocked or partially opened. Ball valves are the best choice for use with gases as they have a stronger seal. They can withstand pressures of up to 700 bar and temperatures of up to 350°C and their sizes usually range from 0.5″ to 48″. Because of their simple construction, they are easy to use and maintain.

Ball valves are reliable, close safely even after long periods of standstill, and are durable and still work well after many cycles. They have a higher resistance to contaminated media than most other types of valves, ensuring a good seal even if the media is not clean. These features make them the best choice for shut-off and control applications where gate and globe valves are often chosen, but they lack the fine control of these alternatives in throttling applications.

Difference between Gate Valves and Ball Valves

One of the most important components of a functional plumbing system is the valve it contains. Valves allow the start and stop of fluid flow, and they need to work well to prevent leakage and excess flow. Although there are many types of valves on the market, the two most common are ball valves and gate valves. This is the information you need to know about the two valve types.

Operation Differences

Ball valves use a rotating ball with a hole and a stem. When the handle attached to the stem is turned, it rotates the ball to open or close the valve. This type of valve is also known as a quarter-turn valve because the handle only needs to be turned 90° (a quarter turn) to allow or stop the flow of the medium. When the handle is parallel to the pipe the valve is open and when the handle is perpendicular to the pipe the valve is closed. For a more in-depth analysis of ball valves, please see our ball valve technical article.

Gate valves use a gate to control the flow of media. The gate is a solid disc structure attached to the stem. The gate is lifted to open the valve and lowered back into position to close the valve. The valve has a bonnet which controls the position of the gate when rotated. This type of valve is also known as a multi-turn valve as it requires more than 360° of rotation to fully open or close the valve. For a more in-depth analysis of gate valves, please see our gate valve technical article.

Valve Seal Capacity Differences

For ball valves, the seal can be fixed for floating ball valve designs or floating for trunnion mounted ball valves. As ball valves are typically used in low pressure applications, given the nature of their operating mechanism, the main seal is usually made of PTFE and other related materials.

Whilst the fast closing and opening of a ball valve is advantageous, this can also cause some problems. Ball valves are susceptible to water hammer or sudden surges in pressure when the valve is closed. This situation can damage the seat of the ball valve.

In addition, water hammer can increase the pressure inside the ball valve. In applications where this can occur, i.e. with combustible materials, there is an emergency valve seat seal, usually made of metal. This is a second barrier in conditions where the resilient seal is damaged in high pressure service. To relieve the pressure, the ball valve can be fitted with a pressure relief device.

The gate valve reduces the pressure drop to a minimum when fully open. This is achieved by using a full orifice design. This means that the size of the valve is equal to the size of the pipe. It is this feature of the gate valve that gives it an advantage over the ball valve. Water hammer does not occur in gate valves.

What is better a gate valve or ball valve?

Ball valves have their advantages and disadvantages, as do gate valves. Ball valves create a tighter seal more effectively, are more reliable and last longer than gate valves, but tend to be more expensive. They are typically used for shut-off and control applications. As ball valves can be opened and closed immediately they are more prone to water hammer than gate valves. So choose gate valve or ball valve, Please make your choice based on the following advantages and disadvantages, or contact ZECO commercial@zecovalve.com to make your selection

Advantages of gate valves

- Low fluid resistance; gate valve body is straight-through design, does not change the flow direction, so that the fluid through the valve (fully open) the least resistance.

- Superior sealing performance; the sealing performance of the globe valve is not as good as that of the gate valve. The gate valve has a faster and easier opening and closing mechanism than other globe valves.

- Bi-directional; gate valves can flow in both directions. They are not limited to one-way flow and are not influenced by the direction of media flow. Gate valves are therefore suitable for use in pipelines with different flow directions.

- Gate valves have a wide range of applications; they are highly adaptable and can be utilised in a variety of media, including steam, oil and other liquids. In addition, the gate valve can be used for media with granular substances and high viscosity. It can also be used as a low vacuum system valve and exhaust valve.

Disadvantages of gate valves

- The opening and closing speeds are slow and the valve must be lifted to the upper part of the chamber during opening and must fall into the seat during closing. As a result, the valve must move a considerable distance to open or close, resulting in long opening and closing times.

- Prone to scratching; excessive friction between the two sealing surfaces of the gate and the valve seat during opening and closing, resulting in scratches on the sealing surfaces. These scratches may seem insignificant at first, but will eventually have an impact on sealing performance and service life.

Advantages of ball valves

- Efficient sealing performance; among other types of valves, the ball valve has a good sealing performance with no leakage.

- Robust; able to withstand high pressures of up to 700 bar and more. They can also withstand high temperatures of up to 350°C.

- Easy to use; available in flanged, welded, threaded, duplex, triple clamp and thin-walled versions. It is simple to set up and use.

- Easy to repair and maintain, extending service life.

- Economical; cost effective valve for any application required.

- Versatile; available as 2-way and 3-way ball valves to convey, divert and converge media.

Disadvantages of ball valves

- Wear and tear; if suspended particles are present in the medium, the valve body and ball valve will wear down, and the valve may be struck.

- More expensive price.

- More possibilities for water hammer

Why is ball valve preferred over gate valve?

In contrast to gate valves, ball valves provide a tight seal and have a complete shut-off characteristic. Therefore, ball valves are more suitable for applications such as natural gas where a proper long-term seal is important

Can I replace gate valve with ball valve?

Because gate valves and ball valves have the same function, then the structural length of gate and ball valves, whether EN558 or AMSE B16.10 or other national standards, are the same structural length for the same bore pressure, so we can be replaced at any time

We are gate valve & ball valve suppliers. If you are interested in our products, please feel free to contact us.

Related Tags :

Ten articles before and after

What Is a Globe Valve And When Is It Made Use Of?

Why Do We Use Butterfly Valve?

Check Valve: The Most Important Valve In a Process System

Backflow Preventer vs. Check Valve: What’s the Difference?

Sealing Elements Of Low-Temperature Bar Ball Valve

The Distinction Between a Butterfly Valve As Well As Gate Valve