When it comes to installing swing check valves, one of the most common questions is: can you install them vertically? In this complete guide, I’ll cover everything you need to know about vertically installing swing check valves.

Can A Swing Check Valve Be Installed Vertically?

The short answer? Yes, swing check valves can be installed vertically in certain applications.

However, there are a few important things to consider before installing one vertically.

Swing Check Valve Design and Specifications

The first thing you need to look at is the specific swing check valve design and manufacturer guidelines.

Some swing check valves are engineered specifically for vertical installation. Others are designed solely for horizontal applications.

Before deciding, closely review the documentation and specs to ensure the valve can operate properly vertically.

Reaching out to the manufacturer directly is also a wise idea. Their team of engineers can provide definitive guidance.

Flow Direction and Performance

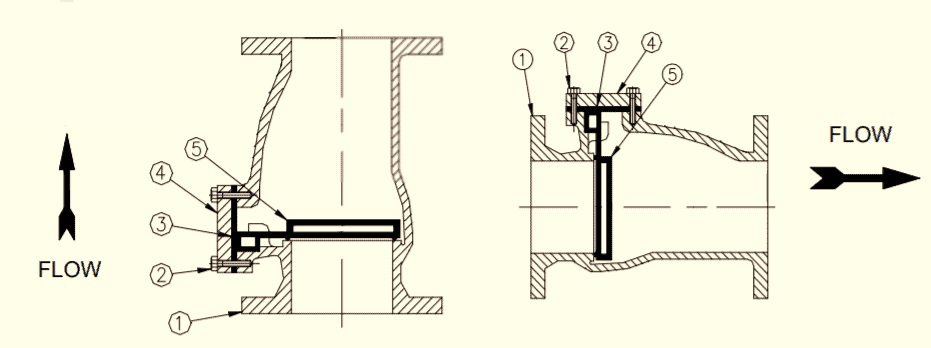

When mounted vertically, flow must travel upward through the swing check valve.

The swinging disc inside needs to open horizontally to allow fluid to pass. And it should close securely to prevent backflow when pressure drops.

If specifications aren’t available, test the valve’s performance before permanently installing to confirm it functions correctly.

Preventing Water Hammer

Rapid valve closure can lead to water hammer. And vertical orientations may increase this risk with certain swing check valve models.

Installing a valve specifically made to prevent water hammer is smart. Upfront cost is minor compared to potential damage over time.

Dual disc and tilting disc check valves are common options to mitigate water hammer risk.

Is Horizontal Still Better?

For most applications, horizontal installation is still ideal for swing check valves. No need to combat gravity. Less water hammer potential.

However, vertical mounting can be an effective orientation as well – if done properly with the right hardware.

When space constraints limit options, vertical is preferable to not using a valve at all in most cases.

5 Key Factors For Vertical Installation

If after reviewing specs and performance you determine a swing check valve can be oriented vertically, keep these five factors in mind:

1. Flow Direction

Confirm flow moves upward through the valve. Prevent downward backflow.

Tilting disc valves excel in vertical pipes. Gravity assists closure. Spring-loaded options add reliability.

2. Expected Flow Rate

Will flow rate fluctuate or run steadily? Cycle speed and volume impact performance.

Higher capacity valves suit applications with frequent or extreme flow changes.

3. Operating Temperature

What temps will the valve handle? Ensure seals and discs withstand exposure over time.

High grade alloys resist wear and deformation from temperature extremes.

4. Pipe Size and Type

Carefully match check valve ends to existing pipe. Typical options:

- Threaded

- Socket Weld

- Butt Weld

- Flanged

5. Accessibility

Can the valve be easily reached for inspection and servicing when mounted vertically?

Full port ball valves installed above and below enable isolation without needing to detach pipes.

Swing Check Valve Alternatives

While swing check valves can work vertically, other options may outperform them.

Spring Check Valves

As the name implies, a spring (rather than backflow) closes these valves once forward pressure ceases.

This makes them effective at preventing water hammer with vertical installations. Less slamming.

They’re available in variety of sizes and materials to suit water, steam, oil, and gas systems.

Nozzle Check Valves

Optimized for when space is extremely tight, nozzle check valves have a compact, cylindrical body that directly connects to pipe walls.

Their integrated spring enables reliable backflow prevention even when installed vertically. Less prone to jamming also compared to other checks.

Piston Check Valves

Featuring a piston and seal rather than hinged disc, these in-line checks deliver reliable performance across a broad array of demanding industrial uses with vertical mounting.

Available in globe, silent, and center-guided designs. Lean towards higher pressure applications.

Conclusion

While horizontal positioning is most widely recommended, swing check valves can be installed vertically when application requirements permit.

Carefully review manufacturer specs, test valve function, and select compatible models to mitigate water hammer risk and long term wear when oriented vertically.

An array of check valve alternatives specifically engineered to excel in vertical installations are also available. Reach out with any questions!