So you’re installing a butterfly valve and wondering: do butterfly valves have a flow direction?

Here’s the short answer:

Table of contents

- Do Butterfly Valves Have a Flow Direction?

- Types of Butterfly Valves and Their Flow Characteristics

- How to Identify the Correct Flow Direction

- Real-World Installation Tips

- Common Mistakes to Avoid

- Industry Standards and Best Practices

- Case Studies: When Flow Direction Goes Wrong

- Advanced Considerations

- Making the Right Choice

- The Bottom Line

Do Butterfly Valves Have a Flow Direction?

It depends on the valve type. Some butterfly valves are bidirectional (work in both directions), while others have a specific flow direction you need to follow.

But here’s the thing:

Even “bidirectional” valves often have a preferred flow direction for optimal performance.

Let me break this down for you.

What Exactly Is a Butterfly Valve?

First, let’s make sure we’re on the same page.

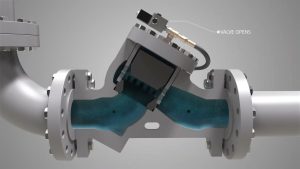

A butterfly valve is basically a disc that rotates inside a pipe. When the disc is parallel to the flow, fluid passes through. Turn it 90 degrees, and it blocks the flow.

Simple, right?

These valves are everywhere:

- Water treatment plants

- HVAC systems

- Chemical processing

- Oil and gas pipelines

The reason they’re so popular? They’re compact, cost-effective, and easy to operate.

Why Flow Direction Matters (More Than You Think)

Here’s something most people don’t realize:

Installing a butterfly valve in the wrong direction can cause:

- Premature wear

- Leakage problems

- Higher operating torque

- Reduced valve lifespan

I’ve seen facilities replace valves every 2-3 years because they ignored flow direction. Meanwhile, properly installed valves can last 10-15 years.

That’s a HUGE difference.

Types of Butterfly Valves and Their Flow Characteristics

Not all butterfly valves are created equal. Let me show you the main types:

Concentric (Centerline) Butterfly Valves

These are your basic, everyday butterfly valves.

The disc sits right in the center of the pipe.

Flow direction: Usually bidirectional

Best for: Low-pressure applications like water distribution

These valves typically don’t care which way the fluid flows. The symmetrical design means equal performance in both directions.

Double-Offset Butterfly Valves

Now we’re getting into high-performance territory.

The disc and stem are offset from the centerline, which reduces friction during operation.

Flow direction: Bidirectional, but with a preferred direction

Best for: Medium to high-pressure applications

Here’s the key: While these can work in both directions, manufacturers often recommend a specific orientation for best results.

Triple-Offset Butterfly Valves

These are the heavy-duty champions.

With three separate offsets, they create a cam-like action that provides bubble-tight shutoff.

Flow direction: Usually has a designated preferred direction

Best for: High-pressure, high-temperature applications

Most triple-offset valves perform significantly better when installed in the recommended flow direction.

How to Identify the Correct Flow Direction

This is where things get practical.

Step 1: Check for Flow Arrows

Most valves with a preferred direction have an arrow cast or stamped on the body.

Found an arrow? Follow it. Simple as that.

Step 2: Read the Documentation

I know, I know. Nobody likes reading manuals.

But manufacturer datasheets contain crucial information about:

- Bidirectional capabilities

- Pressure ratings for each direction

- Installation recommendations

Pro tip: Keep these documents filed for future reference. You’ll thank yourself during maintenance.

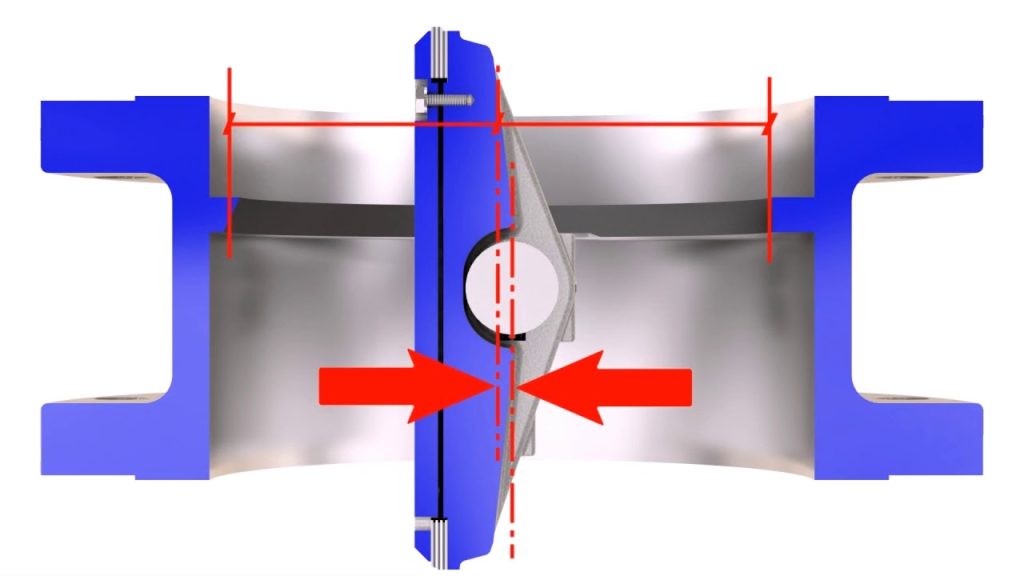

Step 3: Understand Seat-Side vs. Non-Seat-Side

This is a bit technical, but important:

Many valves seal better when pressure pushes the disc against the seat (seat-side).

Think of it like a door. It’s easier to keep closed when wind pushes it against the frame, not away from it.

Step 4: Consider Your Application

Different applications have different requirements:

- Clean water: Usually fine with bidirectional installation

- Slurries or abrasive media: Definitely follow preferred direction

- High-pressure systems: Always follow manufacturer guidelines

Real-World Installation Tips

Let me share what actually works in the field:

Vertical Stem Orientation

For larger valves (12″ and up), install with the stem vertical when possible.

Why? It prevents the disc weight from side-loading the bearings.

Proper Flange Alignment

Misaligned flanges put stress on the valve body. This can cause:

- Difficulty operating

- Premature seal wear

- Potential valve failure

Take the extra time to align everything properly.

Testing After Installation

Don’t assume everything’s fine just because it’s installed.

Test the valve at operating pressure in both directions (if safe to do so). Check for:

- Smooth operation

- Proper sealing

- Acceptable pressure drop

Common Mistakes to Avoid

I’ve seen these mistakes countless times:

Mistake #1: Assuming All Butterfly Valves Are the Same

Just because your last valve was bidirectional doesn’t mean this one is.

Always check each specific valve.

Mistake #2: Ignoring Preferred Direction on Bidirectional Valves

“Bidirectional” doesn’t mean “no preferred direction.”

Following the preferred direction can double your valve’s lifespan.

Mistake #3: Not Considering Future Maintenance

Think about valve accessibility when choosing flow direction.

Will maintenance crews be able to service it easily?

Industry Standards and Best Practices

Let’s talk standards (briefly, I promise).

API 609

This standard covers butterfly valve design and testing. It specifies:

- Pressure testing requirements

- Flow direction considerations

- Installation guidelines

AWWA Standards

For water applications, AWWA provides specific guidance on:

- Valve orientation

- Flow direction marking

- Testing procedures

ISO 5208

International standard for valve testing, including directional flow requirements.

Case Studies: When Flow Direction Goes Wrong

Case Study 1: Municipal Water Plant

A water treatment facility installed 50 butterfly valves backward.

Result:

- 40% experienced leakage within 6 months

- Operating torque increased 30%

- Complete valve replacement required

Cost: $125,000 (could have been avoided)

Case Study 2: Chemical Processing Plant

High-performance butterfly valves installed without checking flow direction.

Result:

- Seat erosion after 3 months

- Process contamination

- Emergency shutdown

Lesson learned: Always verify flow direction for critical applications.

Advanced Considerations

For those dealing with complex systems:

Cavitation Prevention

Proper flow direction can reduce cavitation risk, especially in:

- High-velocity flows

- Large pressure drops

- Volatile fluids

Pigging Operations

If your system requires pigging, butterfly valves might not be ideal regardless of flow direction.

Why? The disc creates an obstruction even when fully open.

Fire-Safe Applications

Fire-safe butterfly valves often have specific flow direction requirements to ensure proper operation during emergencies.

Making the Right Choice

Here’s my advice for selecting and installing butterfly valves:

- Define your application requirements

- Pressure range

- Temperature

- Media type

- Flow reversals

- Choose the appropriate valve type

- Concentric for basic applications

- Offset designs for demanding conditions

- Follow manufacturer guidelines

- Even if it seems unnecessary

- Especially for warranty protection

- Document everything

- Installation direction

- Operating parameters

- Maintenance history

The Bottom Line

So, do butterfly valves have a flow direction?

Many do, and ignoring it can cost you big time.

Even bidirectional valves often perform better in one direction.

The key is understanding your specific valve and application requirements.

Take the time to check for flow arrows, read the documentation, and install correctly the first time.

Your maintenance budget (and your boss) will thank you.

Remember: A few minutes of proper installation can save years of headaches down the road.