Table of contents

- Can Butterfly Valves Be Used for Throttling?

- What Makes Butterfly Valves Different for Throttling

- When Butterfly Valves Actually Work Great for Throttling

- The Dark Side of Throttling with Butterfly Valves

- Design Features That Make Throttling Better

- Best Practices for Throttling Success

- When to Choose Alternative Valves

- Real-World Success Story

- Making the Right Choice

Can Butterfly Valves Be Used for Throttling?

Can butterfly valves be used for throttling? The short answer is yes – but there’s a catch. While butterfly valves can throttle flow, they’re not always the best choice for every throttling application.

Here’s the deal:

I’ve seen plenty of engineers default to butterfly valves because they’re cost-effective and compact. But throttling with a butterfly valve is like using a sledgehammer to crack a nut – it works, but it’s not always pretty.

Let me break down exactly when butterfly valves shine for throttling and when you’re better off looking elsewhere.

What Makes Butterfly Valves Different for Throttling

First, let’s get clear on what we’re talking about.

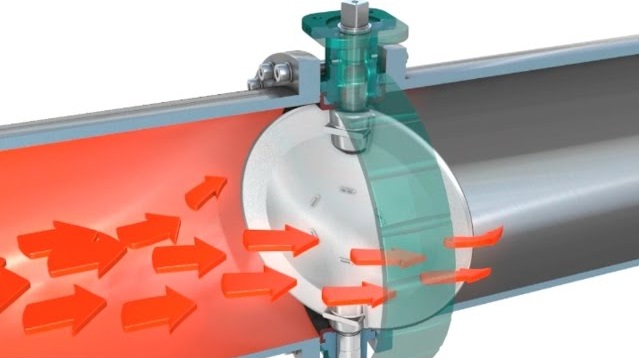

A butterfly valve uses a rotating disc to control flow. When you partially open that disc, you’re throttling – controlling the flow rate by creating resistance.

Simple, right?

Not quite.

Unlike globe valves (which are throttling champions), butterfly valves have some unique characteristics that make throttling… interesting.

For example:

The disc is always in the flow path. Even when fully open, it’s sitting there creating turbulence. This isn’t a big deal for on/off service, but for throttling? That’s where things get tricky.

When Butterfly Valves Actually Work Great for Throttling

Here’s what I’ve found:

Butterfly valves can be excellent for throttling in specific situations. The key is knowing when to use them.

Low to Moderate Pressure Applications

In my experience, butterfly valves perform best for throttling when you’re dealing with:

- Water distribution systems

- HVAC applications

- Low-pressure gas systems

- Cooling water circuits

Why?

Because these applications typically have pressure drops under 50 PSI. At these levels, you’re less likely to run into the nasty problems I’ll cover in a minute.

Large Diameter Pipes

Here’s where butterfly valves really shine.

When you’re dealing with pipes 12 inches or larger, the cost difference between a butterfly valve and a globe valve becomes massive. We’re talking thousands of dollars.

In fact, I recently worked on a project where switching from globe to butterfly valves on 24-inch lines saved over $50,000 in equipment costs alone.

Non-Critical Flow Control

Let’s be honest:

Not every throttling application needs laboratory-level precision. If you’re looking for “roughly 70% flow” rather than “exactly 73.2% flow,” a butterfly valve can do the job just fine.

The Dark Side of Throttling with Butterfly Valves

Now for the bad news.

Throttling with butterfly valves comes with some serious limitations. Ignore these at your own risk.

The Cavitation Monster

This is the big one.

When you throttle with a butterfly valve, you’re essentially creating a restriction that causes a pressure drop. If that pressure drop is severe enough, you get cavitation – vapor bubbles forming and violently collapsing.

The result?

- Noise (sounds like rocks in a blender)

- Vibration

- Rapid erosion of valve components

- Potential catastrophic failure

I’ve seen butterfly valves destroyed by cavitation in less than six months. Not pretty.

Poor Control at Low Openings

Here’s something most people don’t realize:

Butterfly valves have terrible flow characteristics when less than 30% open. The relationship between disc position and flow rate is highly non-linear in this range.

What does this mean in practice?

Moving the disc from 10% to 20% open might triple your flow rate. Not exactly what you want when you’re trying to fine-tune a process.

Increased Wear and Maintenance

When you use a butterfly valve for constant throttling, you’re putting continuous stress on:

- The valve seat

- The disc edges

- The shaft bearings

This accelerated wear means more frequent maintenance and shorter valve life. I typically see throttling butterfly valves need seat replacement 2-3x more often than those used for on/off service.

Design Features That Make Throttling Better

Not all butterfly valves are created equal.

If you’re going to use one for throttling, look for these features:

High-Performance Designs

Double and triple-offset butterfly valves handle throttling much better than basic concentric designs.

Why?

The offset design means the seat contact happens later in the closing cycle, reducing wear during throttling positions.

Special Disc Profiles

Some manufacturers offer butterfly valves with:

- V-port discs

- Characterized discs

- Fish-tail designs

These modifications improve flow control, especially at lower opening percentages.

Hardened Trim Materials

For throttling service, standard soft seats won’t cut it.

Look for:

- Stellite-faced discs

- Metal seats

- Ceramic coatings

Yes, they cost more. But they’ll last significantly longer under throttling conditions.

Best Practices for Throttling Success

Want to throttle with butterfly valves without the headaches? Follow these guidelines:

The 30-70 Rule

Keep your butterfly valve between 30% and 70% open during normal throttling operation.

This sweet spot gives you:

- Better flow control

- Reduced turbulence

- Less wear on components

Size It Right

Here’s a counterintuitive tip:

Sometimes a smaller valve gives better throttling control. A 6-inch butterfly valve running at 60% open often performs better than an 8-inch valve at 30% open.

Monitor and Maintain

Set up a regular inspection schedule. Look for:

- Seat wear patterns

- Disc edge erosion

- Shaft play

- Leakage rates

Catching problems early can mean the difference between a $500 seat replacement and a $5,000 valve replacement.

When to Choose Alternative Valves

Let’s face it:

Sometimes a butterfly valve just isn’t the right tool for the job.

Consider globe valves when:

- You need precise flow control

- The pressure drop exceeds 100 PSI

- You’re handling erosive or corrosive fluids

- The application is critical to process control

Consider control valves when:

- You need automated modulation

- Flow measurement is required

- The process demands exact repeatability

Real-World Success Story

Here’s an example that drives this home:

A water treatment plant I consulted for was using globe valves for throttling on their 16-inch distribution lines. The valves were expensive and required significant maintenance.

We switched to high-performance butterfly valves with characterized discs, keeping them in the 40-60% open range during normal operation.

The result?

- 70% reduction in valve costs

- Adequate flow control for their needs

- Maintenance intervals extended from 6 months to 2 years

The key was understanding their actual control requirements versus their assumed requirements.

Making the Right Choice

So, can butterfly valves be used for throttling?

Absolutely – when applied correctly.

The secret is matching the valve to your specific application. Don’t try to force a butterfly valve into a high-precision throttling role. But don’t overlook them for moderate control applications where their cost and size advantages make perfect sense.

Remember:

The best valve choice isn’t always the most expensive or sophisticated option. It’s the one that meets your actual needs reliably and economically.

Take the time to analyze your throttling requirements honestly. Consider pressure drops, control precision needs, and maintenance capabilities.

When you do that, you’ll find that butterfly valves can indeed be excellent throttling devices – in the right applications.