Ever walked into a building where one room feels like the Arctic while another feels like the Sahara?

Table of contents

- What is a Balancing Valve

- Why Balancing Valves Matter More Than You Think

- How Does a Balancing Valve Actually Work?

- Types of Balancing Valves (And When to Use Each)

- Where You’ll Find Balancing Valves in Action

- The Hidden Benefits Nobody Talks About

- Installation Tips That’ll Save You Headaches

- How to Test and Adjust Balancing Valves

- Common Mistakes That Cost Big Money

- Maintenance That Actually Makes a Difference

- The Cost-Benefit Reality Check

- Future-Proofing Your System

- Making the Right Choice for Your System

- The Bottom Line

What is a Balancing Valve

Here’s the thing: A balancing valve is a specialized control valve that regulates water flow in HVAC and plumbing systems to ensure even distribution of heating or cooling throughout a building.

I’ve seen countless building owners struggle with hot and cold spots, sky-high energy bills, and noisy pipes. And in most cases? The culprit was an unbalanced system.

In this post, as a professional balancing valve manufacturer, let me show you exactly how balancing valves work and why they’re crucial for your system’s performance.

Why Balancing Valves Matter More Than You Think

Think about it this way:

Your HVAC system is like a highway network. Without proper traffic control (balancing valves), some roads get jammed while others stay empty.

The result? Chaos.

I personally witnessed a 30% drop in energy costs after installing balancing valves in a commercial building. That’s not pocket change.

Here’s what happens without proper balancing:

- Some radiators burn hot while others stay cold

- Your boiler works overtime (hello, energy waste!)

- Pipes make annoying noises

- Equipment wears out faster

But when you get it right? Your entire system hums along efficiently.

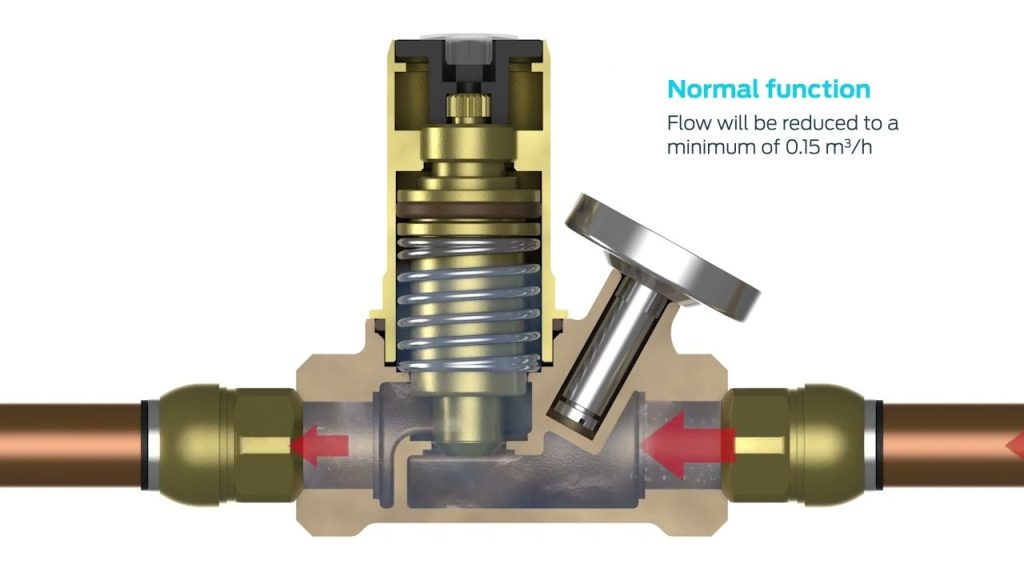

How Does a Balancing Valve Actually Work?

Let’s break this down into simple terms.

A balancing valve creates adjustable resistance in your piping system. Think of it like a volume knob for water flow.

Here’s the basic principle:

- Flow restriction: Inside the valve, there’s an adjustable opening (like a disc or plug)

- Pressure differential: As water flows through, it creates a pressure drop

- Balance mechanism: You adjust this to get the perfect flow rate

The magic happens when you dial in each valve to deliver exactly the right amount of hot or cold water to each zone.

Pro tip: Most balancing valves have measurement ports. This lets you check the actual flow rate with a meter. No more guessing games.

Types of Balancing Valves (And When to Use Each)

Not all balancing valves are created equal.

I’ve installed hundreds of these, and choosing the wrong type is like bringing a knife to a gunfight.

Static (Manual) Balancing Valves

These are your basic workhorses.

- Fixed resistance once set

- Perfect for constant flow systems

- Less expensive upfront

- Requires manual calculation and adjustment

Best for: Smaller residential systems or zones with consistent demand

Dynamic (Automatic) Balancing Valves

Now we’re talking high-tech.

- Self-adjusting to maintain constant flow

- Handles pressure fluctuations automatically

- More expensive but saves money long-term

- No constant tweaking needed

Best for: Variable flow systems, large commercial buildings, or anywhere with changing loads

Thermostatic Balancing Valves

These are the temperature-sensitive specialists.

- Adjusts flow based on water temperature

- Common in domestic hot water systems

- Prevents scalding and ensures consistent temps

Pressure Independent Control Valves (PICV)

The Swiss Army knife of balancing valves.

- Combines balancing, control, and pressure regulation

- One valve does it all

- Higher upfront cost but simplifies installation

I’ve seen building managers save thousands by choosing the right type from the start.

Where You’ll Find Balancing Valves in Action

These valves pop up everywhere water needs precise control.

Commercial Buildings:

- Office HVAC systems

- Hotel room temperature control

- Hospital critical care areas

Residential Applications:

- Multi-zone heating systems

- Radiant floor heating

- Domestic hot water recirculation

Industrial Settings:

- Process cooling systems

- Heat exchanger circuits

- Chiller and boiler systems

Here’s a real example:

I worked on a 50-unit apartment building where half the tenants complained about cold showers. The other half? Scalding hot water.

We installed thermostatic balancing valves on the hot water recirculation system. Problem solved in one day.

The Hidden Benefits Nobody Talks About

Sure, everyone mentions energy savings.

But there’s more to the story.

Reduced Noise

Unbalanced systems create turbulence. That’s the whistling and banging you hear in pipes. Balanced flow = quiet operation.

Extended Equipment Life

When your pump isn’t fighting against improper resistance, it lasts longer. I’ve seen pumps double their expected lifespan.

Better Indoor Air Quality

Proper flow means consistent temperatures. No more moisture problems from cold spots. No more mold growth.

Easier Troubleshooting

With measurement ports on each valve, finding problems becomes simple. Just hook up a meter and check the numbers.

Installation Tips That’ll Save You Headaches

After installing hundreds of these valves, I’ve learned what works.

Location Matters

- Install on the return side of terminal units

- After the control valve, not before

- Keep them accessible for adjustment

Direction is Critical

- Follow the flow arrow (seriously, double-check this)

- Wrong direction = valve won’t work properly

- Some valves are bi-directional, but most aren’t

Proper Sizing

Too big? Won’t control properly.

Too small? Restricts flow too much.

Use the manufacturer’s sizing charts. They exist for a reason.

How to Test and Adjust Balancing Valves

This is where the rubber meets the road.

You’ll need:

- Differential pressure meter

- Manufacturer’s flow charts

- Patience

Step-by-step process:

- Connect meter to test ports

- Measure pressure drop

- Check valve position

- Compare to flow chart

- Adjust until you hit target flow

- Lock the valve setting

Pro tip: Start with the valve farthest from the pump. Work your way back. This prevents constant re-adjustment.

Common Mistakes That Cost Big Money

I’ve seen these errors tank entire projects.

Mistake #1: Skipping the commissioning

Installing valves without proper setup is like buying a Ferrari and never taking it out of first gear.

Mistake #2: Wrong valve type

Using manual valves in variable flow systems wastes energy and money.

Mistake #3: Poor maintenance

These valves need periodic checking. Ignore them and performance degrades.

Mistake #4: DIY calculations

Unless you’re an engineer, use software or hire a pro for system calculations.

Maintenance That Actually Makes a Difference

Good news: Balancing valves are pretty low maintenance.

But “low” doesn’t mean “no” maintenance.

Annual checks:

- Verify flow rates haven’t drifted

- Check for leaks at test ports

- Ensure valve moves freely

Every 3-5 years:

- Full system re-commissioning

- Replace worn gaskets

- Update calculations if system changed

I’ve seen properly maintained valves last 20+ years. Neglected ones? Maybe 5-10.

The Cost-Benefit Reality Check

Let’s talk money.

Initial investment:

- Manual valves: $50-200 each

- Automatic valves: $200-1000 each

- Installation: $100-300 per valve

But here’s what you get back:

- 15-30% energy savings

- Reduced maintenance calls

- Longer equipment life

- Happier occupants

One commercial client saw ROI in 18 months. Not years. Months.

Future-Proofing Your System

The industry is changing fast.

Smart building systems now integrate with balancing valves for real-time optimization. Cloud-based monitoring lets you spot problems before occupants complain.

What’s coming:

- AI-driven flow optimization

- Predictive maintenance alerts

- Integration with weather forecasts

- Automatic seasonal adjustments

Bottom line? Installing quality balancing valves now sets you up for easy upgrades later.

Making the Right Choice for Your System

Every system is unique.

But after years in this business, I can tell you this:

The cheapest option rarely saves money long-term. Quality balancing valves pay for themselves through energy savings and reduced problems.

For residential systems: Start with manual valves if budget’s tight. Upgrade to automatic later.

For commercial systems: Go automatic from day one. The complexity demands it.

For critical applications: PICV valves eliminate variables and ensure reliability.

The Bottom Line

So, what is a balancing valve? It’s your HVAC system’s traffic controller, efficiency booster, and problem solver rolled into one.

Without proper balancing, you’re literally throwing money out the window through wasted energy. With the right valves properly installed and maintained, you get comfort, efficiency, and reliability.

The choice seems pretty clear to me.