Ever wonder why some rooms in your building are freezing while others feel like a sauna?

Here’s the deal:

It’s probably not your HVAC system’s fault. It’s likely a flow balance issue.

And that’s exactly where balancing valves come in.

Table of contents

- How Does a Balancing Valve Work?

- What Is a Balancing Valve (And Why Should You Care)?

- The Two Main Types of Balancing Valves

- Real-World Example: How This Works in Your Building

- The Technical Side (Made Simple)

- Static vs Dynamic: Which One Do You Need?

- The Ultimate Solution: Pressure Independent Control Valves (PICVs)

- Common Mistakes to Avoid

- The Bottom Line on Balancing Valves

- Your Next Steps

How Does a Balancing Valve Work?

How does a balancing valve work? A balancing valve works by introducing a calculated amount of resistance into your fluid system, ensuring every branch gets its intended flow rate. Without these valves, water follows the path of least resistance – meaning units closest to the pump get too much flow while distant units starve.

But here’s the thing:

There’s way more to these valves than just “adding resistance.”

In fact, when I first started working with hydronic systems, I completely underestimated how crucial these little devices were.

(Big mistake.)

So today, as a professional balancing valve manufacturer, I’m going to break down EXACTLY how balancing valves work, the different types available, and why they’re absolutely essential for any modern HVAC system.

Sound good? Let’s dive in.

What Is a Balancing Valve (And Why Should You Care)?

Think of your building’s water system like a highway network.

Without proper traffic control, everyone would pile onto the fastest route. The result? Total gridlock on some roads while others sit empty.

That’s EXACTLY what happens in unbalanced hydronic systems.

The problem without balancing:

- Rooms near the pump = Too hot/cold

- Distant rooms = Wrong temperature

- Your energy bills = Through the roof

- Noise levels = Annoying whistling sounds

A balancing valve acts like a precision traffic controller for your water flow.

Here’s what it does:

- Creates controlled resistance in specific branches

- Ensures equal distribution throughout the system

- Maintains design flow rates regardless of pressure changes

- Saves energy by preventing pump overwork

Pretty important stuff, right?

The Two Main Types of Balancing Valves

Now here’s where it gets interesting.

Not all balancing valves work the same way. In fact, there are two completely different approaches to achieving hydraulic balance.

Let me break them down:

1. Static (Manual) Balancing Valves

Static balancing valves are like setting a permanent speed limit on a road.

How they work:

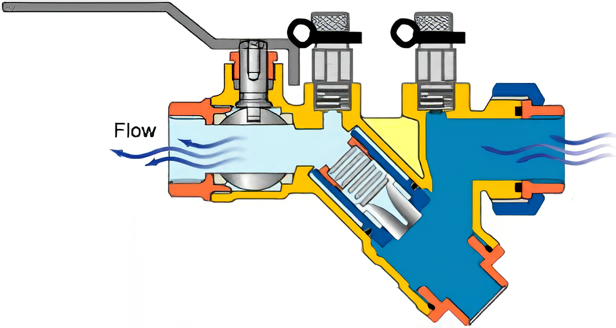

Picture an adjustable disc inside the valve (called an obturator). A technician manually adjusts this disc to narrow the flow path, creating just the right amount of resistance.

Here’s the key part:

These valves have two small measurement ports (P/T ports) that let you measure the differential pressure across the valve. By checking this pressure drop against the manufacturer’s chart, you can calculate EXACTLY how many gallons per minute are flowing through.

The catch?

Once you set it, that’s it. The valve stays in that position forever (hence “static”).

If you add a new room or change your pump speed? You’ll need to manually readjust everything.

I learned this the hard way when a client added an extension to their building. We had to rebalance their entire system from scratch.

(Not fun.)

2. Dynamic (Automatic) Balancing Valves

Dynamic valves are the smart solution.

Think of them as cruise control for your water flow.

Here’s the magic:

Inside these valves sits a spring-loaded cartridge that automatically adjusts based on system pressure.

- Pressure increases? The cartridge compresses, narrowing the opening

- Pressure drops? The spring pushes back, opening wider

The result?

Constant flow no matter what’s happening elsewhere in your building.

Someone closes a valve on the third floor? No problem. The pump speeds up to save energy? Still maintaining perfect flow.

These are absolute game-changers for modern variable-speed pump systems.

Real-World Example: How This Works in Your Building

Let me paint you a picture.

Say you’ve got a 10-story office building with radiators on each floor.

Without balancing valves:

- Ground floor radiators (closest to pump) = Blazing hot

- 10th floor radiators = Barely warm

- Energy waste = Massive

With properly installed balancing valves:

- Every floor = Perfect temperature

- Pump runs at optimal speed

- Energy bills drop by 15-30%

I’ve seen this transformation hundreds of times. And the results never get old.

The Technical Side (Made Simple)

OK, let’s get a bit more technical.

But don’t worry – I’ll keep it straightforward.

When water flows through pipes, it naturally wants to take the easiest path. This creates what we call “differential pressure” – basically, the pressure difference between two points.

Balancing valves work by:

- Measuring this pressure difference

- Calculating the actual flow rate

- Adjusting resistance to achieve target flow

Here’s a pro tip:

The pressure drop across a valve follows this relationship: Flow Rate = K × √(Pressure Drop)

Where K is a constant specific to each valve.

(Don’t worry about memorizing this – manufacturers provide charts that do the math for you.)

Static vs Dynamic: Which One Do You Need?

This is probably the #1 question I get about balancing valves.

And the answer is: It depends.

Choose Static Balancing Valves When:

- Your system has constant flow requirements

- Budget is tight (they’re cheaper upfront)

- You have simple, smaller systems

- Flow demands rarely change

Choose Dynamic Balancing Valves When:

- You have variable-speed pumps

- The system serves multiple zones with different schedules

- Energy efficiency is a top priority

- You want “set it and forget it” operation

My recommendation?

For any modern building in 2025, go dynamic. The energy savings alone typically pay for the higher upfront cost within 2-3 years.

The Ultimate Solution: Pressure Independent Control Valves (PICVs)

Now here’s where things get REALLY interesting.

PICVs are like the Swiss Army knife of valves.

They combine:

- Balancing (limits maximum flow)

- Control (motorized on/off based on thermostat)

- Pressure regulation (automatic compensation)

All in ONE device.

Instead of needing separate control valves and balancing valves, you get everything in a single package.

The benefits are huge:

- Simplified installation

- Perfect temperature control

- Maximum energy efficiency

- Lower maintenance costs

I’ve been recommending these for almost every new commercial project since 2020.

Common Mistakes to Avoid

Let me save you from some painful (and expensive) mistakes:

Mistake #1: Undersizing valves

Too small = excessive pressure drop = wasted pump energy

Mistake #2: Installing in wrong location

Balancing valves need straight pipe runs before and after for accurate measurement

Mistake #3: Not documenting settings

Always record your valve settings. Future technicians will thank you.

Mistake #4: Ignoring maintenance

Even “maintenance-free” valves need periodic checking

The Bottom Line on Balancing Valves

Here’s what it comes down to:

Balancing valves are absolutely essential for any hydronic system that wants to achieve:

- Consistent temperatures throughout the building

- Minimal energy consumption

- Quiet operation

- Long equipment life

They work by creating controlled resistance that ensures every part of your system gets exactly the right amount of flow.

Whether you choose static, dynamic, or go all-in with PICVs, the key is proper selection and installation.

And remember:

An unbalanced system isn’t just inefficient – it’s uncomfortable and expensive to operate.

Your Next Steps

Ready to optimize your system with balancing valves?

Here’s what I recommend:

- Audit your current system – Are you experiencing temperature inconsistencies?

- Calculate your flow requirements – Each zone needs specific GPM

- Choose your valve type – Static for simple systems, dynamic for complex

- Work with qualified professionals – Proper installation is crucial

Trust me:

Getting your hydraulic balance right is one of the best investments you can make in your building’s comfort and efficiency.

The technology has come a long way, especially with modern dynamic valves and PICVs that practically balance themselves.

So there you have it – everything you need to know about how a balancing valve works.

These simple devices might not look like much, but they’re the unsung heroes keeping our buildings comfortable and efficient, one balanced flow at a time.