Ever turned on a faucet and wondered how that water pressure stays just right?

Or maybe you’ve dealt with pipes that bang every time you shut off the water too quickly?

Here’s the deal: What is a water control valve? It’s the unsung hero that keeps your water systems running smoothly, preventing everything from annoying drips to catastrophic pipe bursts.

And trust me, understanding these devices can save you thousands in repairs down the road.

In this post, as a professional water control valve manufacturer, I will break down everything about water control valves for you.

Table of contents

- The Basics: Water Control Valves Explained

- 4 Core Functions Every Water Control Valve Performs

- Types of Water Control Valves (And When to Use Each)

- Real-World Applications That Matter

- How Water Control Valves Actually Work

- Selecting the Right Control Valve (5 Critical Factors)

- Installation Best Practices

- Maintenance That Actually Matters

- Common Problems (And Simple Solutions)

- The Cost Factor

- Advanced Control Valve Tech

- Making the Right Choice

The Basics: Water Control Valves Explained

A water control valve is basically the traffic controller of your plumbing system.

Think about it this way:

Just like traffic lights manage the flow of cars, control valves manage the flow of water through pipes. They can start it, stop it, slow it down, or redirect it entirely.

The bottom line? Without control valves, we’d have water flowing at full blast 24/7. Not exactly practical (or safe).

But here’s where it gets interesting…

4 Core Functions Every Water Control Valve Performs

Control valves aren’t one-trick ponies. They handle multiple critical tasks:

1. Isolation (On/Off Control)

This is your basic shut-off function. Like the main valve to your house that you’d turn off before a vacation.

2. Throttling (Flow Regulation)

Ever adjusted a shower to get the perfect temperature? That’s throttling in action. The valve controls how much water passes through.

3. Directional Control

Some valves ensure water flows one way only. Super important for preventing contamination from backflow.

4. Pressure Management

High water pressure can blow out pipes faster than you can say “plumber.” Pressure control valves keep things in the safe zone.

Types of Water Control Valves (And When to Use Each)

Now, let’s dive into the specific valve types you’ll encounter.

Ball Valves: The Modern Standard

Ball valves dominate modern plumbing for good reason.

Here’s how they work:

A rotating ball with a hole through the center controls flow. Quarter turn = fully open or closed.

Best for: Main shut-offs, quick isolation needs

Pro tip: I’ve found ball valves last 2-3x longer than older gate valves in most applications.

Gate Valves: The Old School Choice

Picture a gate sliding up and down to control water flow. That’s literally what happens inside these valves.

They take multiple turns to open or close, which actually helps prevent water hammer (those annoying banging pipes).

Best for: Large water mains, situations where gradual shut-off matters

Globe Valves: The Precision Players

Globe valves force water to change direction inside the valve body. This design gives you incredibly precise flow control.

Best for: Faucets, outdoor spigots, anywhere you need fine-tuned control

In fact, one study found globe valves can regulate flow within 2% accuracy when properly maintained.

Butterfly Valves: The Space Savers

Lightweight disc that rotates on a central shaft = butterfly valve.

These shine in large industrial applications where space is tight.

Best for: Large diameter pipes, HVAC systems

Check Valves: The One-Way Streets

These automatic valves only allow flow in one direction. No electricity or manual operation needed.

I’ve seen these prevent countless basement floods by stopping sewer backflow.

Real-World Applications That Matter

Let me share where these valves make the biggest impact:

Municipal Water Systems

Cities use massive control valves to:

- Manage water pressure across different elevations

- Isolate sections for repairs

- Prevent contamination through backflow

One water district I worked with reduced water loss by 31% just by upgrading their control valves.

Industrial Operations

From pharmaceutical plants to food processing, control valves ensure:

- Precise temperature control

- Contamination prevention

- Consistent product quality

The stakes? A single valve failure in a pharmaceutical plant can cost millions in lost product.

Residential Applications

Your home probably has 10-20 control valves handling:

- Water heater temperature

- Toilet fill rates

- Irrigation systems

- Main water shut-off

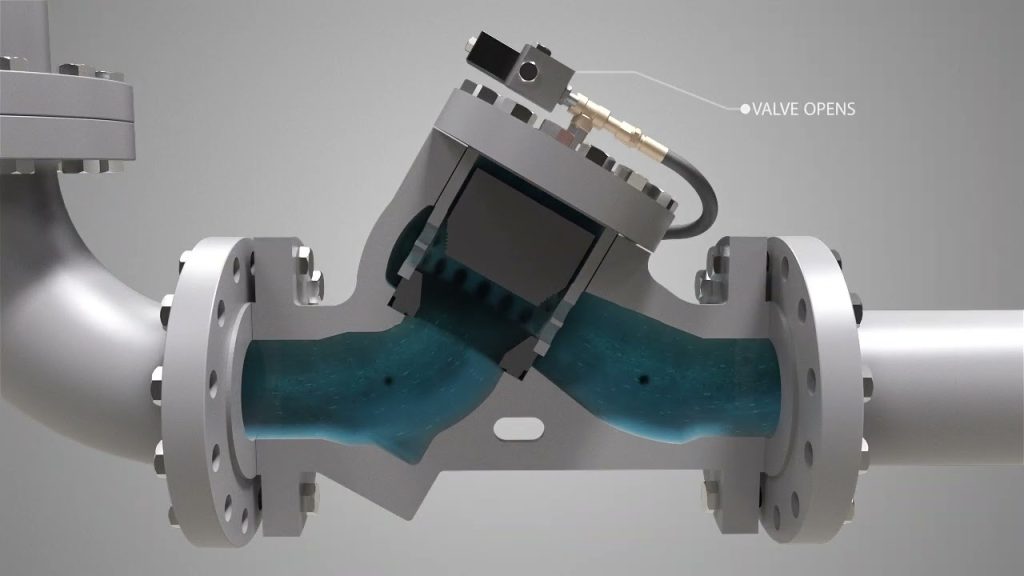

How Water Control Valves Actually Work

Here’s where the magic happens.

Modern control valves use three main components:

1. The Valve Body

This contains the actual flow control mechanism (ball, gate, disc, etc.)

2. The Actuator

The muscle that moves the valve. Can be:

- Manual (hand wheel or lever)

- Electric (motor-driven)

- Pneumatic (air-powered)

- Hydraulic (fluid-powered)

3. The Control System

In automated systems, sensors detect pressure or flow changes. Then they signal the actuator to adjust the valve position.

Pretty clever, right?

Selecting the Right Control Valve (5 Critical Factors)

Choosing the wrong valve is like wearing hiking boots to a marathon. It might work, but you’re in for problems.

Consider these factors:

1. Flow Rate Requirements

Calculate your maximum flow needs. Then add 20% safety margin.

(Trust me, undersizing valves causes more headaches than almost any other mistake.)

2. Pressure Ratings

Match valve pressure ratings to your system. A valve rated for 150 PSI won’t last long in a 300 PSI system.

3. Material Compatibility

Different fluids need different materials:

- Brass for general water use

- Stainless steel for corrosive conditions

- PVC for chemical resistance

4. Temperature Range

Hot water systems need valves rated for those temperatures. Standard valves in hot water lines = early failure.

5. Control Requirements

Ask yourself:

- Do I need simple on/off control?

- Or precise flow modulation?

- Will this be automated?

Your answers determine valve type.

Installation Best Practices

Even the best valve fails if installed wrong.

Here’s what works:

Always install with flow direction arrows

Sounds obvious? You’d be surprised how often this gets missed.

Use proper support

Heavy valves need support brackets. Otherwise, they stress the pipes.

Install isolation valves

Put shut-off valves before and after control valves. Makes maintenance 10x easier.

Add a strainer upstream

Debris destroys valve internals. A $20 strainer protects a $200 valve.

Maintenance That Actually Matters

Want valves that last 20+ years instead of 5?

Follow this routine:

Monthly: Visual inspection for leaks or corrosion

Quarterly: Exercise valves (open and close fully) to prevent sticking

Annually:

- Check and replace seals if needed

- Lubricate moving parts

- Test actuator operation

Pro tip: Keep maintenance logs. Patterns in failures often reveal system issues before they become expensive problems.

Common Problems (And Simple Solutions)

Let’s tackle the issues I see most often:

Valve Won’t Close Completely

Cause: Usually debris or worn seals

Fix: Disassemble and clean, replace seals if needed

Excessive Noise

Cause: Cavitation or high velocity flow

Fix: Check if valve is properly sized, consider adding a pressure reducing valve

Actuator Failure

Cause: Wear, corrosion, or power issues

Fix: Test power supply first, then inspect mechanical components

The Cost Factor

Here’s what nobody talks about:

Quality control valves cost more upfront but save money long-term.

Example from a recent project:

- Cheap valve: $50 (replaced every 3 years)

- Quality valve: $150 (lasts 15+ years)

Total 15-year cost:

- Cheap route: $250 + labor costs

- Quality route: $150 + minimal maintenance

The math is pretty clear.

Advanced Control Valve Tech

The industry is evolving fast.

New innovations include:

Smart valves with IoT sensors

- Real-time flow monitoring

- Predictive maintenance alerts

- Remote control capabilities

Pressure-independent valves

- Maintain constant flow regardless of system pressure

- Huge energy savings in HVAC applications

Electronic actuators with feedback

- Precise positioning

- Diagnostic capabilities

- Integration with building automation

One facility cut energy costs by 23% just by upgrading to smart control valves.

Making the Right Choice

So what’s the bottom line on control valves?

They’re essential for:

- Safety (preventing catastrophic failures)

- Efficiency (optimizing water and energy use)

- Control (getting water where you need it, when you need it)

Start with understanding your specific needs. Then match the valve type to your application.

And remember: investing in quality control valves and proper maintenance pays off every single time.

Because at the end of the day, what is a water control valve? It’s your first line of defense against water system chaos, and choosing the right one makes all the difference in keeping your systems running smoothly for years to come.