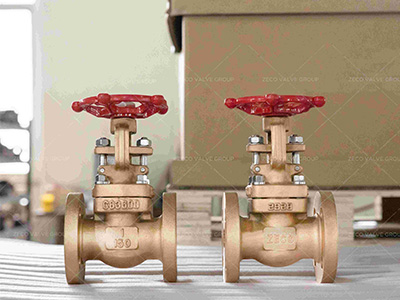

Aluminum Bronze Valves in ASTM B148 C95500, ASTM B150 C63000

Aluminum Bronze ASTM B148 C95500 and ASTM B150 C63000 are suitable for seawater. We manufactured & delivered some check valves, gate valves, and ball valves in special materials to one of our customers in Mexico.

What is ASTM B148 C95500?

Chemical Composition of ASTM B148 C95500

The chemical composition of UNS C95500 copper alloy is given in the following table.

| Element | Content (%) |

| Al, Aluminium/Aluminum | 10.0 – 11.5 |

| Cu, Copper | 78.0 |

| Fe, Iron | 3.0 – 5.0 |

| Mn, Manganese | 3.50 |

| Ni, Nickel | 3.0 – 5.50 |

| Other | 0.50 |

Mechanical Properties of ASTM B148 C95500

| Property | Temperature | Value |

| Elastic modulus | 23.0 °C | 96 – 120 GPa |

| Elongation A50 | 23.0 °C | 5 % |

| Hardness, Brinell | 23.0 °C | 200 [-] |

| Poisson’s ratio | 23.0 °C | 0.34 [-] |

| Tensile strength | 23.0 °C | 760 MPa |

| Yield strength Rp0.5 | 23.0 °C | 415 MPa |

Physical Properties of ASTM B148 C95500

| US Customary | Metric | |

|---|---|---|

| Melting Point – Liquidus | 1930 °F | 1054 °C |

| Melting Point – Solidus | 1900 °F | 1038 °C |

| Density | 0.272 lb/in3 at 68 °F | 7.53 gm/cm3 at 20 °C |

| Specific Gravity | 7.53 | 7.53 |

| Electrical Conductivity | 8% IACS at 68 °F | 0.049 MegaSiemens/cm at 20 °C |

| Thermal Conductivity | 24.2 Btu/sq ft/ft hr/°F at 68 °F | 41.9 W/m at 20 °C |

| Coefficient of Thermal Expansion 68-572 | 9 · 10-6 per °F (68-572 °F) | 15.5 · 10-6 per °C (20-300 °C) |

| Specific Heat Capacity | 0.1 Btu/lb/°F at 68 °F | 419 J/kg at 20 °C |

| Modulus of Elasticity in Tension | 16000 ksi | 110000 MPa |

| Magnetic Permeability* | 1.32 | 1.32 |

| Magnetic Permeability** | 1.2 | 1.2 |

| Poisson’s Ratio | 0.32 | 0.32 |

What is ASTM B150 C63000?

C63000 Aluminum-Bronze Alloy ASTM B 150 is a medium-duty wrought-strengthened product widely used in aerospace, oil and gas, marine, defense, and performance racing.

Applications for C63000 aluminum nickel bronze include hydraulic bushings for earth-moving equipment, aircraft bushings and bearings, heat exchanger flanges and headers, valve balls, sub-sea actuators, pump shafts, valve guides, plunger tips, gears, cams, pump parts, condenser tubes for power station desalting units, and valve seats.

Chemical Composition of ASTM B150 C63000

| Element | Cu | Al | Ni+Co | Fe | Mn | Si | Sn | Zn |

|---|---|---|---|---|---|---|---|---|

| % | Bal | 9.0-11.0 | 4.0-5.5 | 2.0-4.0 | 1.5max | 0.25max | 0.2max | 0.3max |

Mechanical Properties of ASTM B150 C63000

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 760 MPa | 110000 psi |

| Yield strength | 470 MPa | 68200 psi |

| Elongation at break (in 50 mm, 10% reduction in area) | 10% | 10% |

| Elastic modulus | 117 GPA | 17000 ksi |

| Poisson’s ratio | 0.34 | 0.34 |

| Reduction of area (at 316°C/601°F, cold finished) | 9% | 9% |

| Shear modulus | 44.0 GPA | 6380 ksi |

| Fatigue strength (at the number of cycles 1.00e+8, reverse bending) | 255 MPa | 37000 psi |

| Hardness, Rockwell B | 94 | 94 |

| Machinability (UNS C36000 (free-cutting brass) = 100) | 30 | 30 |

Related Tags :

Ten articles before and after

DIN Small Size Globe Valves in Forging Materials – Zeco Valve | Industrial valve manufacturer

API 600 Gate Valves – Zeco Valve | Industrial valve manufacturer

DIN Globe Valves with Small Sizes in Casting Materials – Zeco Valve | Industrial valve manufacturer

News – 5 Electric Ball Valve Manufacturers In USA | API approved valve manufacturer

News – Top 5 Solenoid Valve Manufacturers | API approved valve manufacturer

News – 5 Gate Valve Manufacturers In Europe | API approved valve manufacturer