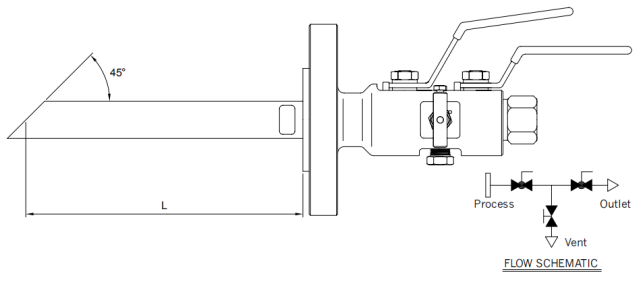

Double block and bleed single flanged valve manifold utilizing soft seated ball valves and a metal seated valve with bonnet to body connection for superior, bubble tight sealing capabilities at both extreme pressures and temperatures.

What is a Sampling Valve?

Sampling DBB valves are used for sampling-injection purposes and further analysis of the process. The valves are designed both with an integral body and sampling probe (not welded). Probe length is defined in accordance with the application requirements and the pipeline diameter.

Technical Specifications of Sampling DBB Valves

| Design | API 6D, API 6DSS, ASME B16.34, ISO 14313, ISO 17292 |

| Design pressure | ASME B16.34, EN 1092-1, ISO 17292 |

| Body wall thickness | ASME B16.34, ASME VIII Div. I, ISO 17292 |

| Face to Face | API 6D, ASME B16.10 Long pattern |

| Temperature range | -50° to 200°C (-58° to 392°F) |

| Pressures range | PN20 (ANSI 150) to PN420 (ANSI 2500) |

| Size range | DN15 (1/2″) to DN150 (6″) |

| End connections | ASME B16.5 Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW ASME B16.11 Socket-Weld SW ASME B36.10 Plain-End PE ASME B1.20.1 Threaded NPT (F/M)) |

How does a Sampling DBB Valve work?

Sampling the process stream can be accomplished with this valve design, where sampling can be taken even at full system pressure directly from the process line. The product allows double isolations from the process for safety.

Features of Sampling DBB Valve?

- Through bore ball-needle-ball configuration

- Reduced and full bore sizes are available

- Flange x thread or flange x flange configurations

- Sampling and chemical injection versions are available

- Handle locking option available

- Fire tested in accordance with BS6755 part II

Applications of Sampling DBB Valve

DBB ball type valve with sampling probe. The probe’s length is normally defined by the customer during the design phase of the application.