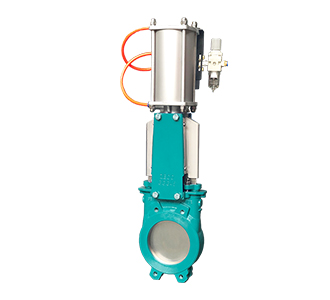

What is a Knife Gate Valve?

Knife gate valve As the name suggests it should be a knife structure with the gate valve equipment, which is a cut off the function of the product, the purpose is to achieve the closure of the valve from the media when the block, knife gate valve with easy operation, open freedom, flexible and reliable, Simple maintenance, excellent sealing performance, and other advantages. So now the knife gate valve is mainly used in what place? How can it work? The next will be for you with a knife-type gate valve which is the main purpose of the relevant content of the introduction.

Knife gate valve main purposes:

- Mine power plant coal preparation, slagging, oil field connected or cut off the pipeline in the ore, slag, slime;

- Food, paper, medicine, urban sewage treatment pipeline in the fiber, wood pulp, pulp, dust, and other media connected or cut off;

- Chemical and other oil, water, and steam pipe, connected or cut off the pipeline in the chemical treatment of sewage, sedimentation tanks, asphalt, silo exports, fruit, grain, slaughterhouse wastewater, and other media;

The use of a knife gate valve, makes up for the traditional, ordinary gate valve deficiency. Knife gate valve into the Chinese market is less than 30 years, during this time, it from the general field of use gradually extended to a wider range of industries, from the use of coal to food and other living industries, knife gate valve These uses not only changed the industrial production but also changed our lives.

How does a Knife Gate Valve work?

Knife gate valve, also known as knife gate valve, knife type slurry valve, it’s opening, and closing parts is the gate, the direction of movement of the gate and the fluid direction perpendicular to the fiber can be cut by cutting the blade to cut the media, Two sealing surfaces, the most commonly used mode gate valve two sealing surface to form a wedge, wedge angle with the valve parameters vary, usually 50, wedge knife gate valve can be made as a whole, called the rigid gate; Can also be made to produce trace deformation of the gate, in order to improve its craft, to make up the sealing surface angle in the processing of the deviation, this gate is called the elastic gate. The valve body does not actually exist in the chamber, the gate in the side of the guide groove lift, and by the bottom of the lug pressed in the valve seat, for a higher media seal, the choice of O-shaped seal seat to achieve Two-way seal. The knife gate valve has a small installation space, low working pressure, easy to accumulate debris, and the price is low.

When the knife gate is closed, the sealing surface can be sealed only by the medium pressure, that is, by means of the medium pressure to press the sealing surface of the gate to the other side of the valve seat to ensure that the sealing surface seal, which is self-sealing. The gate valve is forced to seal, that is, when the valve is closed, it is necessary to rely on external force forced to push the valve seat to ensure that the sealing surface sealing. This type of valve in the pipeline should generally be installed horizontally.

Specifications of Knife Gate Valves

Size Range: 1 1/2″-48″/DN40-DN1200

Temperature: (-)29℃ to (+) 120℃

Allowable Operating Pressure: PN10/PN16

Manual, electric, pneumatic, hydraulic, bevel gear, electro-hydraulic, and gas-liquid drive, and other driving methods. Knife gate valve shape: Ming rod, dark rod two. Knife gate material: cast iron, cast steel, carbon steel, stainless steel, lining fluorine and so on. Knife gate valve seal: hard seal, soft seal, single-sided seal, double-sided seal, and other materials sealed.

Where are Knife Gate Valves Used?

- Mining, coal washing, iron and steel industry-used for coal washing pipelines, filter slurry pipelines, etc., ash discharge pipelines;

- Purification device used for waste water, mud, dirt, and clarified water with suspended matter;

- Paper industry-used for any consistency of pulp, material, and water mixture;

- Deashing of power station used for ash slurry.

Performance Of Knife Gate Valves

- For remote control, but also in accordance with the requirements of users to achieve remote location display and remote control.

- Lightweight: the body is made of carbon steel, the weight of the traditional valve weight reduced by about 20% -30%, easy to installation, and maintenance.

- The use of the valve can improve the delivery line system closed sealing performance, maximize the leakage, improve production efficiency, and protect the environment will play a positive role in promoting.

- Sealing surface with high wear-resistant, corrosion-resistant ceramic materials, the use of mosaic technology, high corrosion resistance, wear resistance, which makes the valve long life, cost more ordinary valve 10 times.

Features Of Knife Gate Valves

- Lift the gate seal surface, can scrape the sealing surface of the adhesive, and automatic cleaning debris.

- The stainless steel gate prevents corrosion caused by leakage of the seal.

- The hard gold seal surface ensures the seal’s wear resistance and requirements.

- The valve body sealing surface without grooves does not produce accumulated objects, to ensure flexibility to open.

- Short structure length can save raw materials, and installation space is also effective to support the pipeline strength.

- The scientific seal on the stuffing box is designed so that the seal is safe and effective, durable.

- Triangular stent to save raw materials, to ensure the required mechanical properties.

- The valve body on the guide block so that the correct movement of the gate and four compression blocks to ensure an effective sealing plate.

- The valve body is designed to improve the strength of the valve body.

- Stainless steel stems are durable, and double-headed bolts make the opening and closing more quickly.

- Can be an arbitrarily selected drive mechanism.

- 150 or more caliber, the use of a fully enclosed structure, is more effective to open and prevent leakage.

- Fluorine rubber sealing surface to achieve the sealing effect, and improve the use of temperature.

- The rubber sealing surface directly in the body of the vulcanization, will not fall off.

Related Tags :

Ten articles before and after

Ball Valve Attention To Fire And Fire – News – Zeco Valve | Professional valve manufacturer

The Electric Valve Can Not Be Closed – News – Zeco Valve | Professional valve manufacturer

Central Air Conditioning Electric Valve Which – News – Zeco Valve | Professional valve manufacturer