Pipeline maintenance is a critical task for industries across the globe, ensuring the smooth operation and longevity of their pipeline systems. A key player in this process is the pigging ball valve, a specially designed component that facilitates efficient cleaning, inspection, and overall maintenance of pipelines. So, what exactly are pigging ball valves and how do they function within different applications? Let’s dive right in!

What are Pigging Ball Valves?

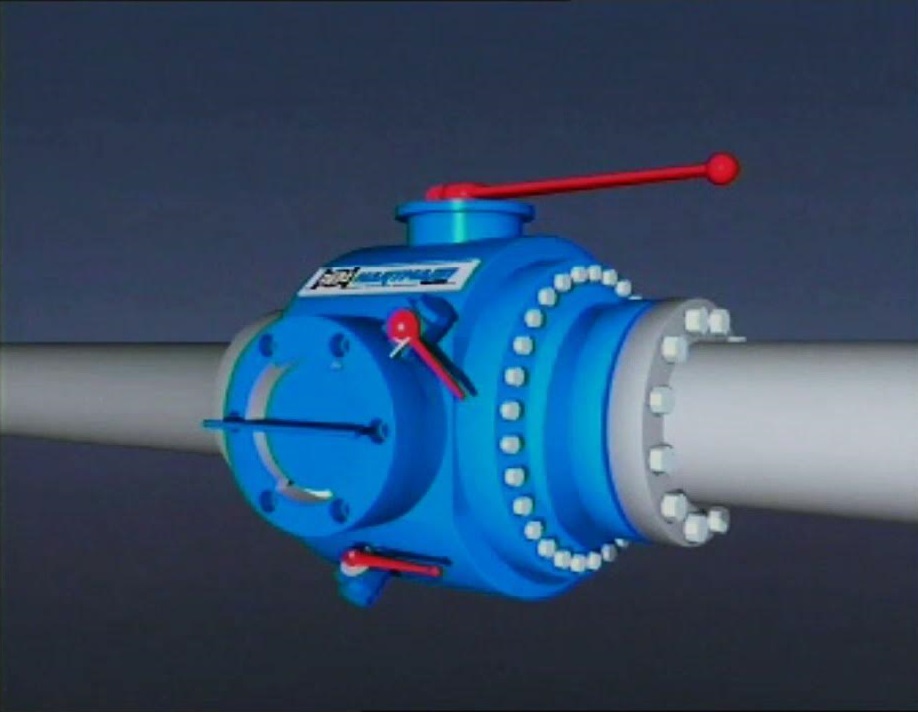

Pigging ball valves get their name from the device they accommodate – the ‘pig’. This device is inserted into a pipeline to clean or perform other maintenance tasks. The pigging ball valve allows this device to move freely through the pipeline while also providing a tight seal when closed to prevent leaks or blockages.

The real magic of these valves lies in their various designs, each offering unique features catering to different applications. Some common types we’ll explore include Full Port, Reduced Port, V-Port, and Trunnion-Mounted Pigging Ball Valves.

What are the Different Types and Applications of Pigging Ball Valves?

Full Port Pigging Ball Valves: Unrestricted Flow

Full port pigging ball valves offer an unrestricted flow due to their full-sized bore matching the diameter of the pipe. They facilitate easy passage for pigs through pipelines which makes them popular in industries like oil & gas or chemical & petrochemical where regular maintenance and cleaning are paramount.

Reduced Port Pigging Ball Valves: Versatility at Its Best

Reduced port variants have a smaller opening than full-port ones but still provide an effective flow control solution and allow passage of pig devices. Their versatile nature enables them to be used across industries like food & beverage, pharmaceuticals, etc., where efficient removal of contaminants/sediments plays a significant role.

V-Port Pigging Ball Valves: Precision in Control

V-Port pigging ball valves stand out with their distinct V-shaped orifice design that offers precise control over fluid flow while accommodating pigs’ movement. These valves find favor in industries like water treatment, chemical processing, etc., where accurate flow regulation is needed.

Trunnion-Mounted Pigging Ball Valves: The Reliable Choice

Featuring additional mechanical anchoring on top and bottom of the ball for a secure connection between ball and stem, trunnion-mounted pigging ball valves provide reliable sealing even under high pressure and temperature conditions making them perfect for demanding applications such as those found in the oil & gas industry.

Conclusion

In conclusion, exploring different types of pigging ball valves help make informed decisions about what’s best suited for specific applications contributing towards enhanced efficiency and integrity and overall lifespan pipelines next time you plan to maintain/upgrade your pipeline remember to choose right because little knowledge goes a long way! From high-pressure setups needing trunnion-mounted variants precision controlled operations preferring v-port designs choosing the right one can make a massive difference in process outcome ensuring optimal performance lifetime pipeline system.

FAQs

Pigging ball valves play an instrumental role by letting pigs move through pipelines smoothly for efficient cleaning, inspection, or other routine tasks while maintaining a tight seal preventing leakages/blockages thus enhancing the efficiency & lifespan of pipelines.

No, every type offers unique features catering to different requirements. For instance, full port ones offer unrestricted fluid flow making them ideal where regular cleaning/inspection is needed; reduced port ones offer versatility being functional across many industries; v-port ones offer precision control suited to specific industries needing accurate flow regulation; trunnion-mounted ones can withstand high pressures/temperatures making them suitable for demanding applications.

It depends on your specific requirements – factors like design size and materials compatibility with pig operations need consideration before you select any particular type as a replacement.

Primarily stainless steel resistant to corrosion/wear ensures longevity and durability especially under demanding environments though material choice may vary based on specific application demands.

Any visible signs of wear tear leakage disruption in smooth functioning might indicate the need for repair/replacement best course would be consulting experts timely manner avoiding potential system failures.