Description

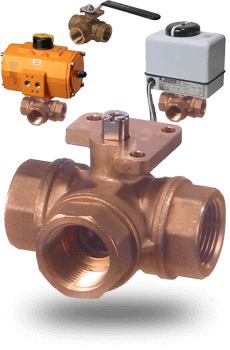

3 way brass ball valves are used in applications with more than one source of media or to divert media in two different directions.

What is a 3 Way Brass Ball Valve?

3 Way Brass Ball Valves are designed to divert flow in different directions as needed. All valves are “L” style, but “T” style are also available. These valves are ideal for use in a variety of chemical and liquid applications. Locking handles and female FPT ports are standard. All valves are manually operated, but include mounting pads for actuators or position indicators if required.

What are 3 Way Brass Ball Valve Used For?

Three way brass ball valves have three ports and can be manually operated or automated with an electric or pneumatic actuator. The bore through the ball comes in two varieties: “L” and “T” port. Three way valves can:

- Cut off or shut off flow

- Switch flow between two different sources

- Combine the flow from two different sources

- Alternate flow between two different destinations

- Divert flow coming from one source to another destination

- Split flow coming from one source between two outgoing destinations

Technical Specifications of 3 Way Brass Ball Valves

| Body Material | Brass |

| Stem Material | Brass |

| Ball Material | Chrome Plated Brass |

| Seat Material | PTFE |

| Stem Seals Material | PTFE, with Viton® O-ring, or RPTFE |

| End Connections | NPT Threaded (1/4″ to 3″) |

| Temperature Range: | -30 to 320°F |

| Pressure Range: | up to 400 PSIG |

Advantages of 3 Way Brass Ball Valves

- Standard port

- Blow-out proof stem

- Live-loaded Pyramidal stem seal design

- Integrated mounting pad for actuators

- Compact assembly

- Complete line of accessories

Applications of 3 Way Brass Ball Valves

- Air Drying Equipment

- Pollution Control Equipment

- Process Control Applications

- Laundry Equipment

- Textile Dyeing & Drying

- Bottling & Dispensing Equipment