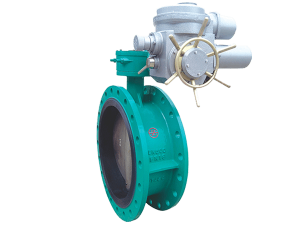

Flanged Butterfly Valve

Description

Flanged Butterfly Valve

Festures of Flanged Butterfly Valve

- Bidirectional sealing, no flow direction of the medium;

- Valve body vulcanized EPDM, reliable sealing;

- A dial with an opening indication showing the position of the disc switch;

- Flow characteristics straight line, good regulation performance.

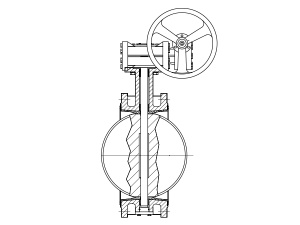

Flanged Butterfly Valve Working Principle

The rotary center of the flanged butterfly disc (that is, the center of the stem) is located on the centerline of the valve body and the sealing surface section of the disc. When the disc is closed, the disc’s circular sealing surface squeezes the synthetic rubber seat so that the seat produces elastic deformation and forms the elastic force to seal the butterfly valve. If the remote control is required, different types of electric devices can be equipped according to different working conditions.

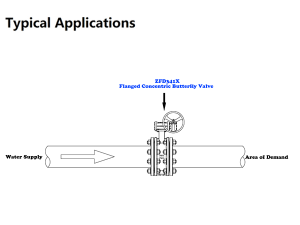

Flanged Butterfly Valve Installation and Commissioning

Clean the inner cavity and sealing cover of the valve before installation. This butterfly valve can be installed on the horizontal, vertical and any Angle pipe, and can be used in both directions. The butterfly valve must be in the closed position during installation to ensure that the disc does not collide with the pipe flange. Make sure the flange welding is correct. After the butterfly valve is installed, it is not allowed to weld the flange again, so as not to burn the rubber parts and the anti-corrosion coating. For specific use, please consult ZECO Valve Group.

Flanged Butterfly Valve Material and Standard

Size Range: 2″~48″

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

| Part | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Disc | Ductile Iron | EN 1563/DIN 1693 |

| Seat | EPDM / NBR | ISO 4633 |

| Stem | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Bolt | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Worm Actuator | Ductile Iron | EN 1563/DIN 1693 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||