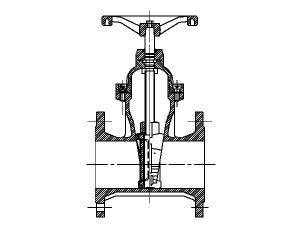

Description

Features of Resilient Seated Gate Valve

- Full diameter flat – bottom runner, no debris pooling;

- Fully covered EPDM disc, no corrosion;

- Movable disc’s nut, adaptive offset;

- The variable pressure change O-Ring.

Resilient Seated Gate Valve Working Principle

The main seal is entirely rubber covered gate, under the action of operating force and hydraulic pressure produced a small amount of adaptive elastic deformation, and precision casting of the seating stroke excellent sealing effect.

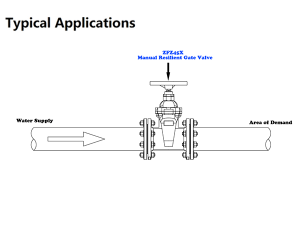

Resilient Seated Gate Valve Installation and Commissioning

If maintenance is required, the o-ring can be replaced online directly on the pipe. When installed, pay attention to the use of temperature and corrosivity, can be used to replace rubber parts suitable for the use of temperature. For specific use, please consult ZECO Valve Group.

Resilient Seated Gate Valve Material and Standard

Size Range: 2″~48″

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

| Part | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Bonnet | Ductile Iron | EN 1563/DIN 1693 |

| Stem | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Wedge | Ductile Iron + EPDM / NBR | EN 1563/ISO 4633 |

| Nut | CuZn39Pb1 / C37000 | EN12167/ASTM B135 |

| Handwheel | Ductile Iron | EN 1563/DIN 1693 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||