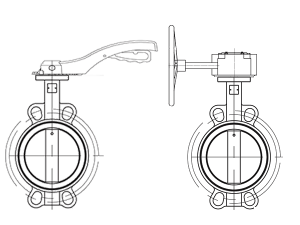

Wafer Butterfly Valve

Description

Wafer Butterfly Valve

Festures of Wafer Butterfly Valve

- simple and compact in structure, light in weight, easy to assemble and repair;

- Small operation torque, turn 90° portable rapid opening and closing;

- Small flow resistance, the energy saving effect is good;

- Reliable sealing, leakage is zero, long service life.

Wafer Butterfly Valve Working Principle

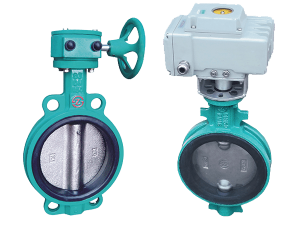

Large diameter can be increased due to the increase of torque, which can be increased by adding a turbine head or electric actuator. Electric actuators can be equipped with common type, household type, explosion-proof type and regulating type according to different working conditions, which can realize remote control and computer networking.

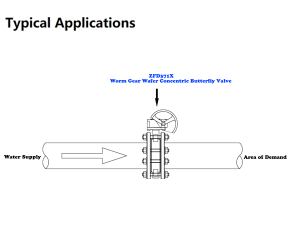

Wafer Butterfly Valve Installation and Commissioning

This valve must be equipped with butterfly flange. Put the butterfly valve into the middle of the special flange at both ends of the pipeline, and use the double head bolt through the pipeline flange and clamp butterfly valve to lock tightly, then it can be used normally. For specific use, please consult ZECO Valve Group.

Wafer Butterfly Valve Material and Standard

Size Range: 2″~48″

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: EN 558-2008

Flange End Dimension: EN1092-2, ISO 7005-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: EN 1074-1 and 2, EN 12266

| Part | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Disc | Ductile Iron | EN 1563/DIN 1693 |

| Stem | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Handle | Ductile Iron | EN 1563/DIN 1693 |

| Seat | EPDM | ISO 4633 |

| Bushing | CuZn39Pb1 / C37000 | EN12167/ASTM B135 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||