Wafer Type NRV

Description

ZECO Valve is a reputed Check Valve Manufacturer engaged in designing fine-quality industrial valves. We offer a wide range of valves that are robust in their design, user-friendly, modular and extremely durable.

What is NRV Wafer Type?

ZECO wafer type NRV has a shorter face-to-face dimension and dual plate design, the end connection options include wafer type, lug type and double-flange type, and are available in size from 2″ to 60″ and in pressure ratings from ASME class 150 through 2500. A wide range of body and trim materials are optional on customer’s request. Compared to conventional swing check valves, ZECO’s wafer type NRV have the advantage of zero leakage toward outside (no bolted or threaded connections), cost savings, they can be installed in any line orientation, superior seal performance, offer minimal line shock, lower pressure loss and zero seat wear.

NRV Wafer Types

SINGLE DISC CHECK VALVE

Light weight, versatile design – 80% to 90% less than conventional full-body swing check valves Single Disc opening, Single integrated arm/ disc assembly, Spring-loaded disc calculated to increase the responsiveness of the disc, Elastomer o-ring seat secured in body with dove-tail groove, Integrated body seat, Non-blow out shaft design. Optimizes space utilization, Lowers installation costs, Reduces pipe supports, Requires less number of man-hours, Unobstructed flow Stable disc at lower flow velocities, No shearing of disc from arm, Non-rotating disc for longer life.

NON SLAM CHECK VALVE

Disc Check Valve is advanced designs which gives full flow and occupy very less space than other type of Non Return Valve. DCVs are simple to fit between two pipe flanges. Spring loaded disc to prevent reverse flow in pipe lines. Stronger, lighter and smaller than conventional swing check valves, hence less expensive to install and maintain. Compact Design of valves flexibly accommodates various types of flange selection. The valves can be fitted in any direction in pipelines. Zero leakage for soft seated valves.

DUAL PLATE CHECK VALVE

The dual Plate Check Valve is an all purpose non return valve that is much stronger, lighter in weight and smaller in size compared to a conventional swing check valve or life check valve. Dual Plate Check Valve has cylindrical body which makes the valve look like any other pipe fitting. A cylindrical body has much more uniform distribution of stress compared to a conventional swing check valve. A cylindrical body of the pressure containing part of the Dual Plate Check Valve can be designed to withstand extreme much to the weight (thickness) of valve. Thus for severe/ rugged loading conditions, these valves have a distinct edge over the conventional valves both in terms of safety and economics besides general versatility. The Dual Plate Check Valve employs two spring-loaded plates hinged on a central hinge pin. When the flow decreases, the plates close by torsion spring action without requiring reverse flow. This design offers the twin advantages of No Water Hammer and Non Slam simultaneously. All features put together make the Dual Plate Check Valve one of the most efficient design. Dual Plat Check Valves are available in wafer design, flanged wafer design and extended design with flanged ends having face to face dimensions as that of a swing check valve.

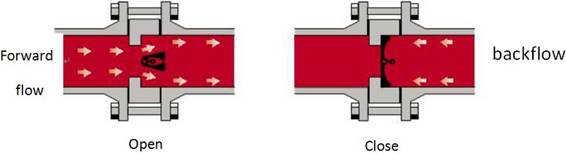

How does a Wafer Type NRV work?

A wafer-type non-return valve operates based on pressure differential. This is a difference in pressure between the inlet and outlet ports of the wafer-type NRV. The valve disc opens when the inlet pressure is more than the outlet pressure. This pressure provides the force needed to flap the valve discs. When the discs are flapped they leave space for the fluid to flow through the valve. The discs remain open provided there is high suction pressure than the outlet side. When the suction pressure reduces or fluid attempts to reverse flow, the spring gains energy to revert the valve plates to their seating position thus helping in preventing reverse fluid flow.

Features of Wafer Type NRV

- The dual plate design of ZECO wafer type NRV incorporates an internal retention fitting. The fitting does not encroach the gasket sealing surface, to ensure the effective seal between valve and pipeline;

- The dual plate wafer design of ZECO wafer type NRV makes this check valve lighter, which is only 10~25% of the weight of conventional swing check valve, to saves money in initial valve cost and provides lower installation cost;

- The spring feature of ZECO wafer type NRV aids in keeping the valve closed and the lighter weight in eliminating pipeline bending loads make the valve flexible installed in any position, to allow you to design your piping layout in the most efficient and least expensive method;

- When the valve opens, the heel of the dual plate is lifted in the direction of the flow, to avoid that the heel drag across the seating surface and cause wear. When closing the valve, both the two high torsion springs and the back pressure will force disc toe and heel back in turn to the flat seat to complete the seal.

- Wafer-type non-return valves operate on their own without the use of a handwheel or valve actuator.

- These valves do not allow reverse fluid flow. The fluid flows in the forward direction and any attempt to reverse is restricted as the valve closes immediately.

- These valves have high efficiency relative to other valves because their pressure drop is minimal.

- Wafer-type non-return valves are designed to maintain working fluid pressure.

- Wafer-type NRV is versatile as they are used in various applications from household to industrial applications.

- These valves are easy to install, repair, and clean.

- They are free from fluid leakage.

- Wafer-type non-return valves alleviate water hammer and related effects.

- They are light in weight relative to other non-return valves.

- These valves are can be installed in either horizontal or vertical positions since they do not depend only on gravity to prevent reverse fluid flow.

- Wafer type NRV are fasting acting relative to other valves such as globe valves.

Applications of Wafer Type NRV

- Steam

- Hot & cold water

- Power & heat engineering

- Pressurized Air

- Industrial technologies

- Fluids without acidity or alkalinity properties

Specification of NRV Wafer Type

| Single Disc Check Valve | API 594 / API 6D |

| Non Slam Check Valve | API 594 |

| Dual Plate Check Valve | API 594 |

| Flanged End Dimensions | ASME B16.5, ASME B16.47 A & B |

| Valve Inspection & Testing | API 598 |

| Visual Inspection | MSS SP 55 |

| Non Destructive Test (RT, UT, MT, PT) | ASME B16.34 |

| Pressure – Temperature Rating | ASME B16.34 |

| BODY | CI IS 210 GR FG 200/220/CS ASTMA 216 GR WCB /SG IRON/ CF8/SS 304 / CF8M/SS 316 /CF3/CF3M/GUN METAL/ALUMINIUM |

| PIN | MS/AISI 304/ AISI 316 |

| RINGS | NBR/NEOPRENE /NITRILE /SILICON/ VITON/PTFE/STL/INTREGAL |

| SIZE RANGE | 25NB TO 1200 NB (1″ TO 48″) |

| PRESSURE CLASS | 150# to 1500# |