Wastewater Air Release Valve

Description

Wastewater Air Release Valve

Festures of Wastewater Air Release Valve

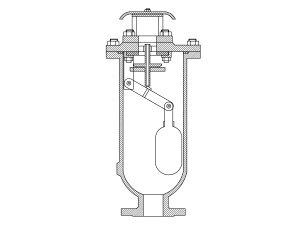

This valve principle is the same as the clean water air release valve, but the structure is slightly changed, valve body lengthened, the lever structure slightly changed. This will reduce the control part, so that the dirt only in the lower part of the body, will not wind the upper exhaust part of the structure, will not affect the exhaust, will not leak water.

Wastewater Air Release Valve Working Principle

- Dirt can only be on the lower part of the body without winding the upper vent;

- Can remove the gas in the pipe, reduce the resistance and save energy;

- When the tube is under negative pressure, it can inhale quickly and automatically;

- Float ball is stainless steel, long service life, safe and reliable.

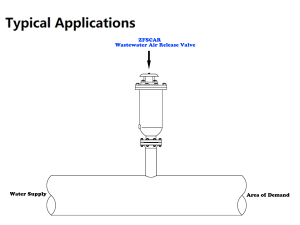

Wastewater Air Release Valve Installation and Commissioning

If the discharge valve is not installed, the pipe will be blocked at any time, resulting in the outlet water capacity of the pipe is not up to the design requirements. For specific use, please consult ZECO Valve Group.

Wastewater Air Release Valve Material and Standard

Size Range: 2″~10″

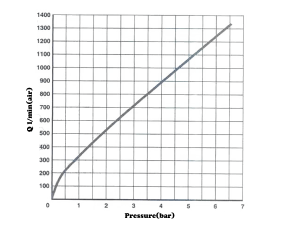

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

| art | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Bonnet | Ductile Iron | EN 1563/DIN 1693 |

| Exhaust Hood | Ductile Iron | EN 1563/DIN 1693 |

| Float Ball | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Strainer | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Seal | EPDM / NBR | ISO 4633 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||