Only by fully understanding single seat and cage-guided globe control valves can they be used correctly. This article helps you understand them better.

What is Globe Control Valve?

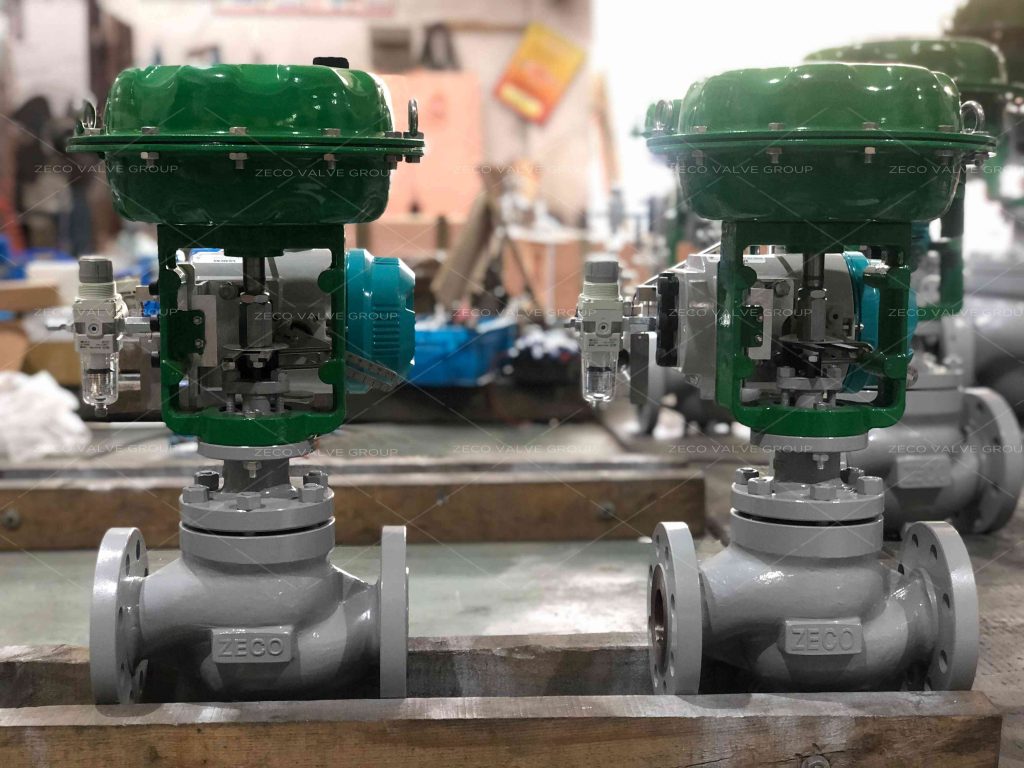

A globe control valve uses a linear motion to move a closure member into and out of a seating surface. They have a body distinguished by a globular-shaped cavity around the port region and are designed to regulate process flow when used in conjunction with an actuator assembly. Many single-seated valve bodies use a cage or retainer-style construction to retain the seat-ring, provide valve plug guiding, and provide a means for establishing particular valve flow characteristics. Cage or retainer-style single-seated valve bodies can also be easily modified by change of trim parts to change the flow characteristic or provide reduced-capacity flow, noise attenuation, or reduction or elimination of cavitation.

Excellent Accuracy with Globe Control Valve

- Accuracy and precision

- Globe control valves provide superior control performance and high reliability in a wide range of applications. They are designed to provide accuracy, precision, and reliability in both general and more demanding services. They can be found in service in a wide range of customer industries, from oil & gas, chemical, and petrochemical to power plants and pulp & paper mills.

- Safety and sustainability

- Globe control valves are engineered, built, and tested to be both safe and sustainable. They ensure the lowest possible emissions in accordance with ISO 15848 and in most cases certified fire safety according to API 607. Our globe valves are also SIL 3 certified. Special cleaning options are also available for oxygen and cryogenic services for example.

Single Seat Globe Control Valve

Definition

Single Seat Globe Control Valve, the trim is interchangeable in the body. It’s content to various technics liquid process by replacing the different trim assembled.

Tehnical Specification

| SIZES | 0.5” to 12” (15mm to 300mm) |

| RATINGS | ASME 150-600 |

Application

The single-seat globe control valve is the furthest common control valve type, a simple structure, is used for the strict sealed close situation. A single-seat globe control valve can be controlled the maximum flow rate by changing the size of the plug and seat ring. setting fluid characteristics by changing the curved surface. They are applicable in a wide scope of liquid services as well as steam services.

Structure

Among different types of valve bodies, single-seated valves have trim structures with the easiest collocation, for example, angle valves. As a result of high-pressure fluid is generally held the load to add the whole area of the bottom seat, making the single plug to be endured huge unbalanced force from fluid, relative to the control valve with balanced trim, the allowable pressure drops are much less for the single-seated valve on the process control.

Trim Options

| CONTOURED TRIM | The contoured tip option is used on most applications and is suited to low-pressure drops. It includes a plug with a contoured head, the profile of which permits a high-pressure recovery. |

| SOFT-FACED | This version offers bubble-tight shutoff, thanks to a different plug design, which features a clamped-on shroud. This ensures a high degree of closure, by locking the soft-faced ring in position. |

Cage Guided Control Valve

Definition

Cage Guided Control Valve, cage structure, straight stroke control valve. the trim is interchangeable in the body Its content to various technics liquid processes by replacing the different trim assembled.is designed focused on high-pressure drops, effectively reducing the effects of cavitation and the noise in the high-pressure drops services. favorable Interchangeability, be reached different flow characteristics by replacing different cages, to get much higher precision of control. Can be reduced noise, and dispelled the effects of cavitation by replacing trim.

Tehnical Specification

| SIZES | 1” to 24” (25mm to 600mm) |

| RATINGS | ANSI 150-4500; API 5,000 – 15,000 |

| BODY MATERIALS | Carbon Steel / Low Temperature Carbon Steel / Alloy Steel / Stainless Steels / Duplex & Super Duplex / Inconels |

| TRIM THROTTLING MATERIALS | Carbon Steel / Low Temperature Carbon Steel / Alloy Steel / Stainless Steels / Duplex & Super Duplex / Inconels |

Application

Cage Guided control valve size is in common use for 1-12, an actuator for standard diaphragm type. On a metal seat, the suitable temperature range is -196 +538, and on a soft seat, the suitable temperature range is -45 +200. It’s content with most industrial process control.

Structure

The most excellent cage-guided structure control valve is balance characteristic, for plug balance ports function, fluid pressure acted on static unbalance force of plug, it reduced unbalance force, then the valve can be configured actuator smaller than conventional single seat valve.

The most simple structure of a cage-guided control valve is twin-seat, the twin-seat structure is applicable to situations the requirement of leakage is not high. The cage-guided single-seat control valve has a sliding seal between the plugs top of the cage. by seals function, dispelling the leak that upriver fluid entered the low-pressure downriver system. So it has the tightly closed characteristic as a conventional single seat valve, moreover has balance characteristic.

Trim Options

| MICRO / MULTI-SPLINE | The Microspline and multi-spline trim is designed for high-pressure-drop liquid services on applications with low flow rate requirements. These trims are supplied in valve sizes up to 2” (50mm) in diameter. The flow sleeve and plug are constructed as an insertable cartridge, with up to five stages of pressure drop to ensure that cavitation does not occur throughout the stated flow range. The multi-spline trim option can achieve rangeabilities in excess of 100 to 1, due to the very precise fit of the plug within the seat. The standard material is full stellite Grade 6. However, there are also tungsten carbide and advanced ceramic options for pressure drops greater than 100 bar (1450 psi). |

| ‘HF’ HIGH FRICTION | The ‘HF’ High Friction trim is suited to most process-control applications and helps reduce cavitation and noise in a low-pressure recovery application. For more severe applications it can include stellite or tungsten carbide inserts. |

| MULTI-STAGE HIGH FRICTION | This trim helps reduce the likelihood of cavitation in high friction liquid or reduce noise in large pressure drop gas applications. Two or more concentric sleeves have many grooves incorporating radial holes. This creates a tortuous radial flow which dissipates energy within the cage by splitting and impinging the flows, meaning that the final stage of letdown has a smaller pressure drop. The main features are: Divides the main flow into many small streams, increasing turbulence and noise peak frequency and maximizing the pipe wall transmission loss. High energy levels, pressure, and velocity are dissipated within the trim – avoiding erosion damage. The design of the final stage ensures low-velocity non-interacting jets, avoiding unnecessary noise generation in the valve outlet. Various sizes can be used on different control valve body sizes, to suit a wide range of process control parameters. |

ZECO Valve offers high-quality Single Seat and Cage Guided Globe Control Valves, please feel free to contact us if you need them.

Related Tags :

Ten articles before and after

A Guide to Ball Valves(1) | API 6D ball valve manufacturer

A Guide to Ball Valves(2) | API 6D ball valve manufacturer

When Is a Butterfly Valve Used? | API 6D ball valve manufacturer

Why Choose Butterfly Valve? | API 6D ball valve manufacturer

How to Choose a Globe Valve, and How does It Work? | API 6D ball valve manufacturer

Features of the Cage guided valve | API 6D ball valve manufacturer

Knife Gate Valve VS Gate Valve | API 6D ball valve manufacturer

Are the valves closed clockwise and opened counterclockwise? | API 6D ball valve manufacturer

Should We Use a Soft Seal or a Hard Seal for the Butterfly Valve? | API 6D ball valve manufacturer

Factors Affecting the Sealing Performance of Globe Control Valves | API 6D ball valve manufacturer